6

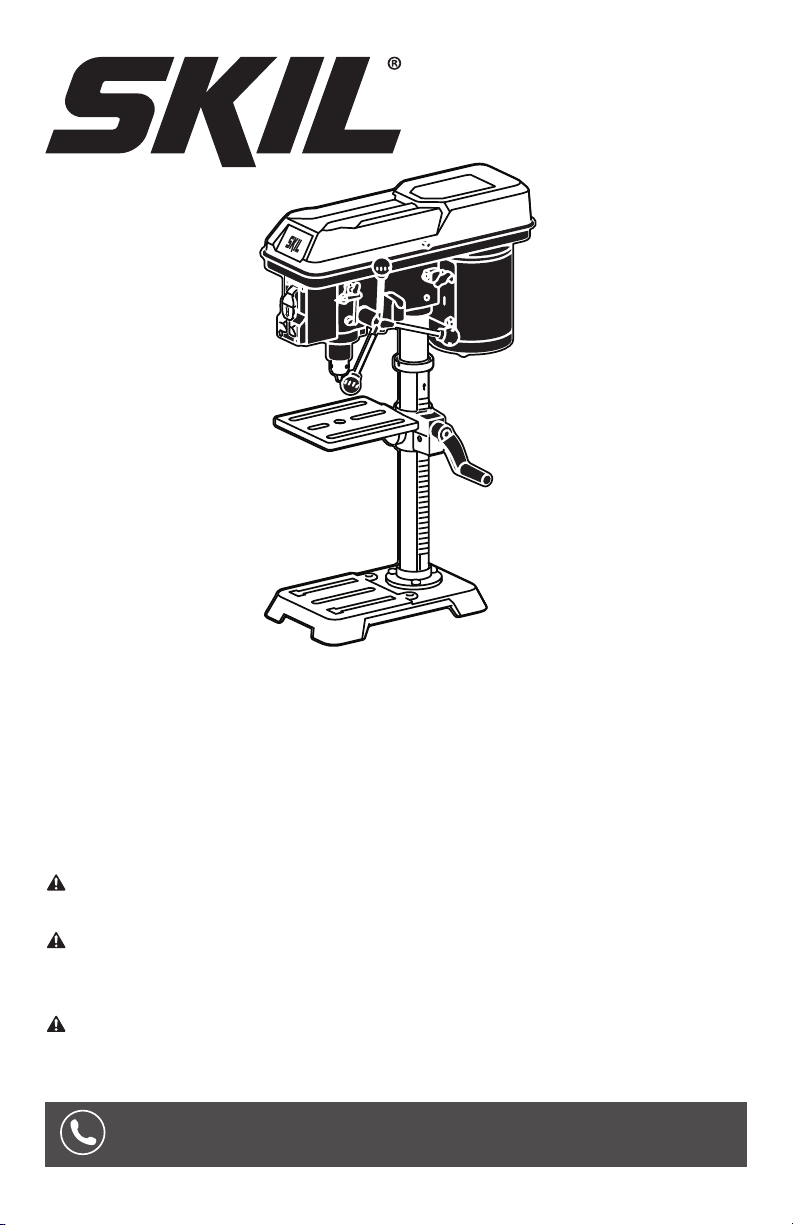

• Never move the head or table support while the tool is running.

• Before starting the operation, jog the motor switch to make sure the drill bit or other cutting

tool does not wobble or cause vibration.

• If a workpiece overhangs the table such that it will fall or tip if not held, clamp it to the table

or provide auxiliary support.

• Use xtures for unusual operations to adequately hold, guide and position the workpiece.

• Use the SPINDLE SPEED recommended for the specic operation and workpiece material—

check the panel inside the pulley housing cover for drilling information; for accessories, refer

to the instructions provided with the accessories.

e. Never climb on the drill press table; it could break or pull the entire drill press down on you.

f. Turn the motor switch “OFF” and unplug from power source when not in operation.

g. To avoid injury from thrown work or tool contact, DO NOT perform layout, assembly, or

setup work on the table while the cutting tool is rotating.

h. Clamp workpiece or brace against column to prevent rotation.

i. Before starting, be certain chuck key is removed from chuck and that motor head and table

are locked.

j. Keep pulley housing cover closed when not making belt adjustments.

k. Do not expose to rain or use in damp locations.

USE ONLY ACCESSORIES DESIGNED FOR THIS DRILL PRESS TO AVOID SERIOUS

INJURY FROM THROWN, BROKEN PARTS OR WORKPIECES.

a. WHEN CUTTING LARGE DIAMETER HOLES: Clamp the workpiece rmly to the table.

Otherwise the cutter may grab and spin at high speed. Use only one-piece, cup-type, hole

cutters. DO NOT use y cutters or multi-part hole cutters as they come apart or become

unbalanced in use.

b.Drum sanders must NEVER be operated on this drill press at a speed greater than the

speed rating of the drum sander.

c. Do not install or use any drill bit that exceeds 7” (17.8 cm) in length or extends 6”

(15.2 cm) below the chuck jaws. They can suddenly bend outward or break.

d. Do not use wire wheels, router bits, shaper cutters, circle (y) cutters, or rotary

planers on this drill press.

e. Use recommended speed for drill accessory and workpiece material.

f. Accessories must be rated for at least the spindle speed setting of the drill press.

This drill press has 5 spindle speeds. Check spindle speed setting of the drill press based

on pulley speed chart located inside the pulley housing cover. Ensure accessories used has

a higher speed rating than the current spindle speed setting of the drill press. Accessories

running over their rated speed can y apart and cause injury.

DIRECTION OF FEED FOR DRUM SANDING

WARNING Feed workpiece into a sanding drum (or other approved accessory)

against the direction of rotation.

WARNING A kickback occurs when workpiece suddenly binds on the cutting edge of

the cutter and the workpiece is thrown by the cutter in the direction of the

cutter’s rotation. This can cause serious injury.

THIS DRILL PRESS HAS 5 SPEEDS: 610 RPM, 950 RPM, 1500 RPM, 2050 RPM AND

2800 RPM.

See inside of pulley housing cover for specic placement of belt on pulleys.