18

6. Maintenance

The maintenance must be considered a set of procedures that aims to keep the equipment

in opmum operang condions, resulng in increased service life and safety.

* Cleaning – Check item 3.3 of this manual Cleaning.

* Wiring-Check all the cables on the decay and all contacts (terminals) on the grip and

electric corrosion.

* Contacts – on/offswitch, emergency stop buon, reset buon, electronic circuits,

etc. Check the equipment so that all components are funconing properly and that the

operaon of the appliance is normal.

* Installaon – check the installaon of your equipment according to item 2.1, Installaon

of this manual.

* Product life-2 years, to a nomal working turrno.

1-items to check and perform monthly:

-Check the wiring;

-Measure the voltage from the socket;

-Measure the operang current and compare with the nominal;

-Check ghtness of all electrical terminals of the unit, to avoid possible bad contacts;

-Check possible furloughs electric motor sha;

-Check the wiring and electrical cable for signs of overheang, poor insulaon or

mechanical failure.

2-checking Items or perform every 3 months:

-Check electrical components like power switch, emergency stop buon, reset buon and

electronic circuit for signs of overheang, poor insulaon or mechanical failure.

-Check possible clearances in bearings and bearings.

-Check seals, rings o’rings, v rings rings and other fencing systems.

3

1. Introducon

1.1 Security

This equipment is suitable for grinding meat boneless and unfrozen, and is potenally

dangerous when used improperly. It is necessary to perform maintenance, cleaning and/or

any service by a qualified person and with the equipment disconnected from the electrical

network.

The instrucons below should be followed to avoid injury:

1.1.1 read all instrucons.

1.1.2 to protect against risk of electrical shock and equipment damage, never use the same

with: clothes or wet feet and/or in damp or wet surface, do not immerse in water or any

other liquid and do not use water jet directly on the equipment.

1.1.3 should always be supervised when using any equipment, especially when it is being

used near children.

1.1.4 Disconnect the equipment from power when: it’s not in use, before cleaning,

removing accessories, introducon of accessories, maintenance and any other type of

service.

1.1.5 do not use the equipment if you are with damaged cord or plug. Make sure that the

power cord does not remain on the edge of the table/counter or touch hot surfaces.

1.1.6 when the equipment suffer a fall, is damaged in any way or does not work it is

necessary to take it to an authorized service center for examinaon, repair, electrical or

mechanical adjustment.

1.1.7 the use of accessory aachments not recommended by the appliance manufacturer

may cause injury.

1.1.8 keep hands and any utensil away from moving parts of the appliance while it is

running to prevent personal injury or damage to equipment.

1.1.9 Never wear with wide sleeves, especially on the wrists during the operaon.

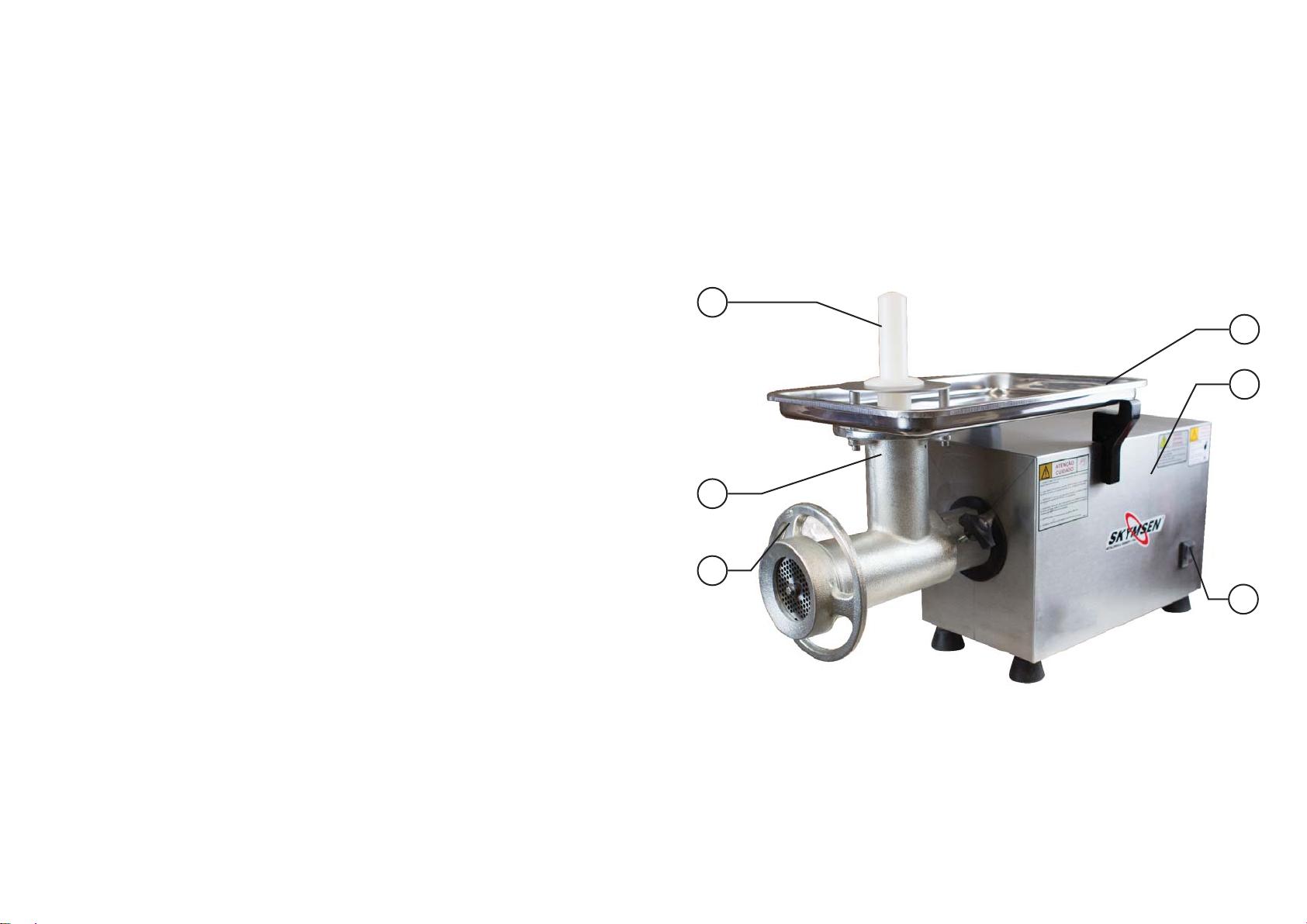

1.1.10 before connecng the equipment, check if the mouth N° 02 (fig. 01) is firm in its

posion, and if all its internal components are mounted correctly as shown in Figure 03.

1.1.11 this product was developed for use in commercial kitchens. Is used, for example, in

restaurants, canteens, hospitals, bakeries, butchers and similar.

The use of this equipment is not recommended when:

-The producon process is connuously on an industrial scale;

-The workplace is an environment with corrosive atmosphere, explosive, contaminated

with steam, dust or gas.