2

SUMMARY

1. Introducon ...................................................................................... 3

1.1 Safety .................................................................................................................... 3

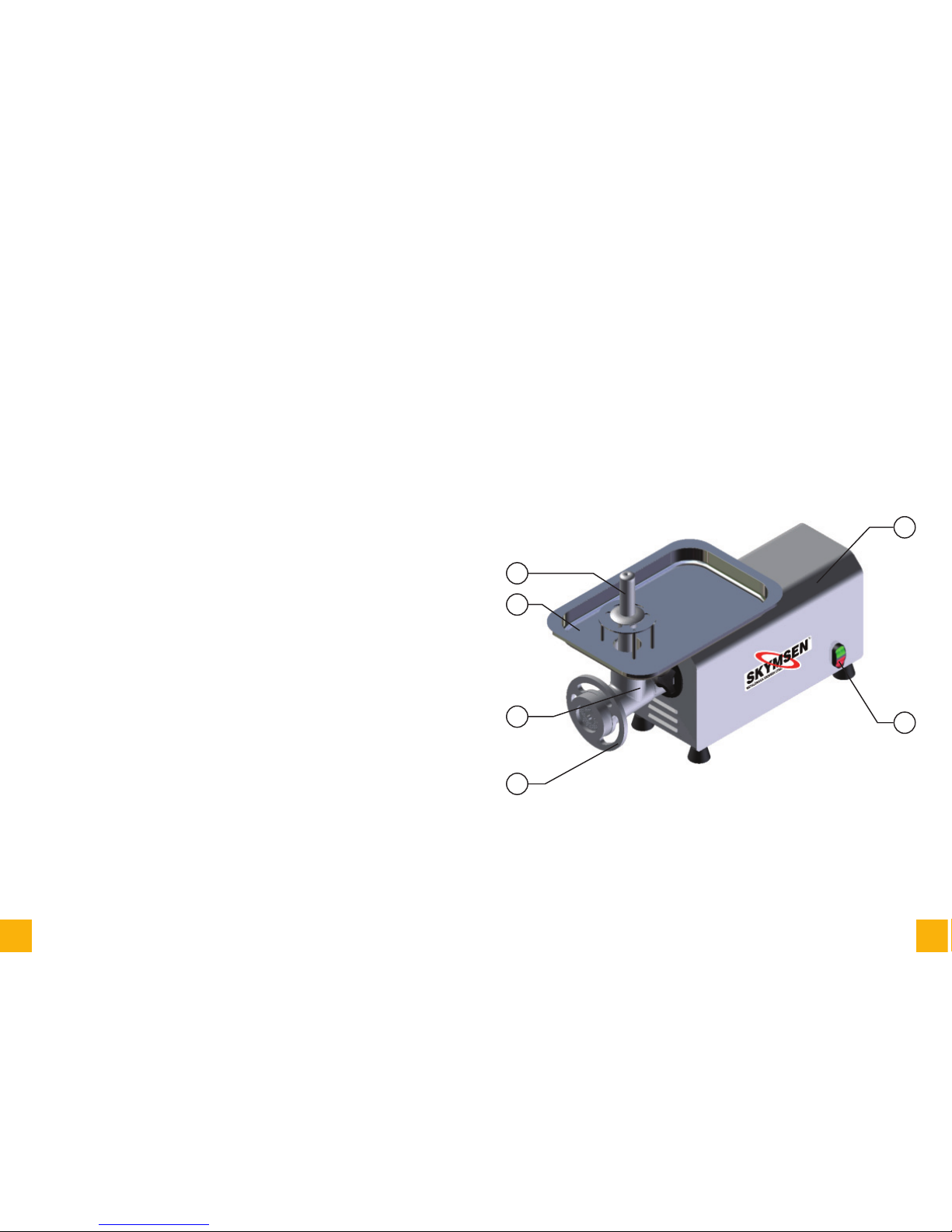

1.2 Main Components ................................................................................................. 5

1.3 Technical Characteriscs ........................................................................................ 6

1.4 Labels .................................................................................................................... 6

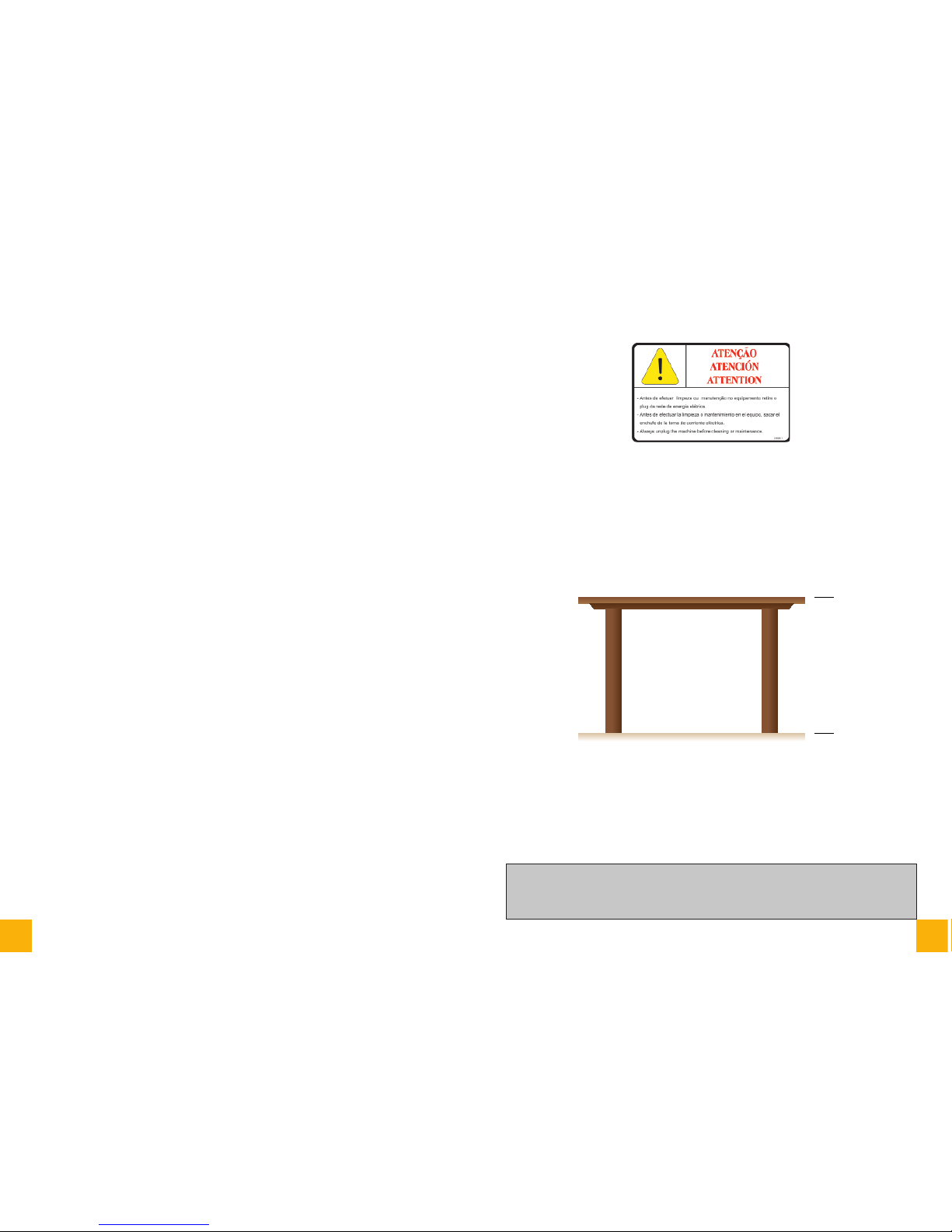

2. Installaon and Pre Operaon ........................................................... 7

2.1 Installaon ............................................................................................................ 7

2.2 Pre Operaon ........................................................................................................ 8

3. Operaon ......................................................................................... 8

3.1 Starng ................................................................................................................. 8

3.2 Operaon Procedure ............................................................................................. 8

3.3 Safety System ........................................................................................................ 9

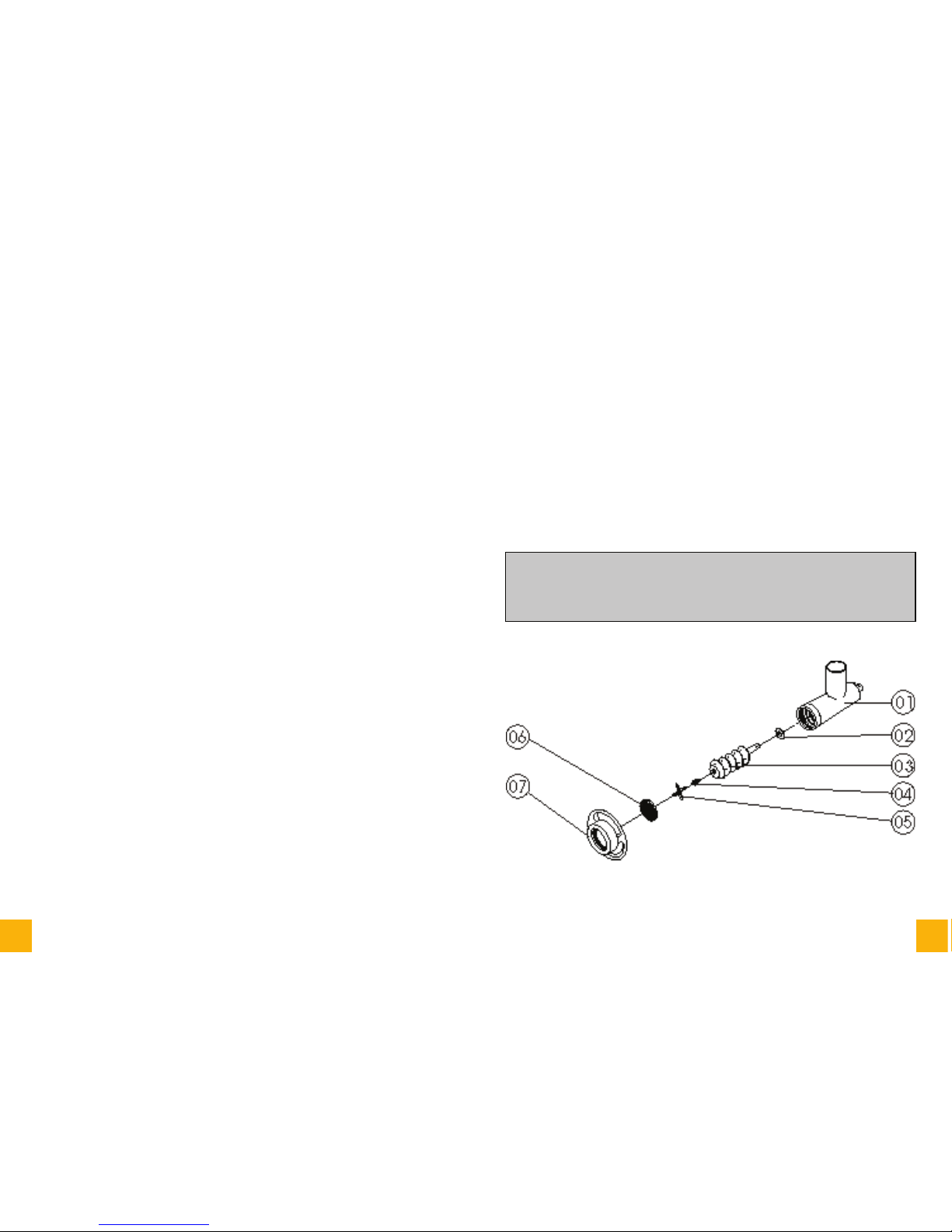

3.4 Assembling the Barrel internal components ......................................................... 9

3.5 Cleaning and Sanizing ........................................................................................10

3.6 Cauons with Stainless Steel ................................................................................10

4. General Safety Pracces .................................................................. 12

4.1 Basic Operaon Procedures ..................................................................................12

4.2 Safety Procedures and Notes Before Switching the Machine On ...........................13

4.3 Roune Inspecon ..............................................................................................14

4.4 Operaon .............................................................................................................14

4.5 Aer Finishing the Work .......................................................................................14

4.6 Maintenance ........................................................................................................15

4.7 Advices ................................................................................................................15

5. Analyses and Problem Solving ......................................................... 16

5.1 Problems, Cause and Soluons .............................................................................16

5.2 Components Adjustment and Replacement .........................................................16

6. Maintenance ................................................................................... 18

7. Electric Diagram .............................................................................. 19 23

___________________________________________________________

___________________________________________________________

___________________________________________________________

___________________________________________________________

___________________________________________________________

___________________________________________________________

___________________________________________________________

___________________________________________________________

___________________________________________________________

___________________________________________________________

___________________________________________________________

___________________________________________________________

___________________________________________________________

___________________________________________________________

___________________________________________________________

___________________________________________________________

___________________________________________________________

___________________________________________________________

___________________________________________________________

___________________________________________________________

___________________________________________________________

___________________________________________________________

___________________________________________________________

___________________________________________________________

___________________________________________________________

___________________________________________________________

___________________________________________________________

___________________________________________________________

___________________________________________________________

___________________________________________________________

___________________________________________________________

___________________________________________________________

___________________________________________________________

___________________________________________________________

___________________________________________________________

___________________________________________________________

___________________________________________________________