3

1. Introducon

1.1 Safety

This equipment is suitable to grind meat without bones and defrosted and if not correctly

used it may be potenally DANGEREOUS. Maintenance, cleaning or any other service are

to be done by a qualied person with the machine unpluged.

To avoid accidents, injures and damages to the equipment, follow the below instrucons :

1.1.1 Read carefully the complete instrucons.

1.1.2 To avoid the risk of electric shock and damage to the equipment never use the

equipment with wet clothes or wet feet, nor on a wet oor, never dip the equipment or

spray water or any other liquid on it.

1.1.3 When in use the equipment must always be watched, specially when children might

be near.

1.1.4 Unplug the equipment from electric network when not in use, before to clean it,

before to place or remove any accessory,, during maintenance or any other kind of service

1.1.5 Do not use any equipment having a damaged cord or plug.

Make sure the cord not to lean on a table edge, nor to touch a hot surface.

1.1.6 If the equipment has fall, is damaged or do not switch on take it to a Technical

Assistance to be checked, repaired or adjusted.

1.1.7 Do not use accessories not recommended by the manufacturer.

1.1.8 Keep your hands or any tool away from the parts in movement to avoid corporal

injures or equipment damage.

1.1.9 Never use clothes with wide sleeves during operaon.

1.1.10 Make sure the equipment voltage is the same as the network voltage and that the

equipment is duly grounded.

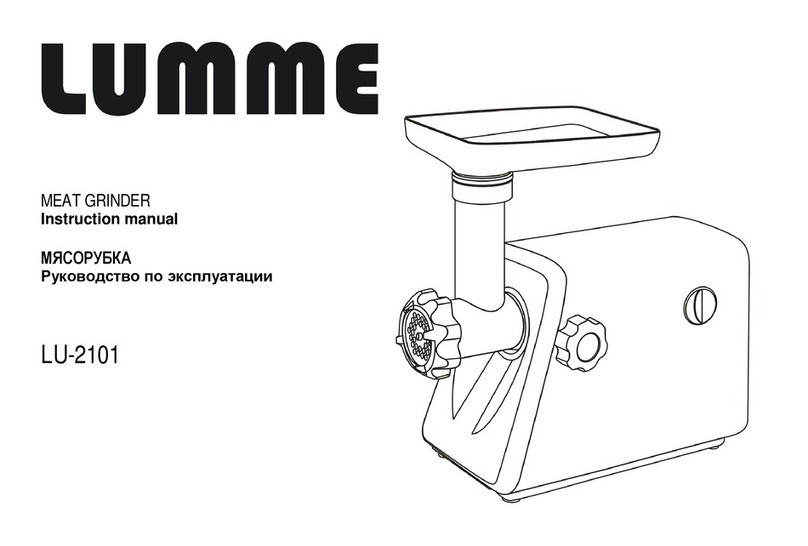

1.1.11 Before to start the equipment, make sure the Barrel.# 02 (Pic 01) Is rm in its

posion and all its internal components are correctly assembled, see Picture 02.

1.1.12 This equipment has been developed for commercial operaon, it is used for instance

in restaurants, fast foods, hospitals, bakeries, butchers and similar.