CAUTION

1. If the electrical supply fails, settings are ‘held’ for a short period.

2. If the air pressure fails with power ‘on’ the solenoid will ‘flutter’.

3. If the monitor output functions is not used, ensure that the wire is

totally insulated.

Fig 5

PNP Circuit

Note: If the supply exceeds 30mA the sensor will output to the LED

display (Fig 1) and show ‘Er 5’.

CAUTION

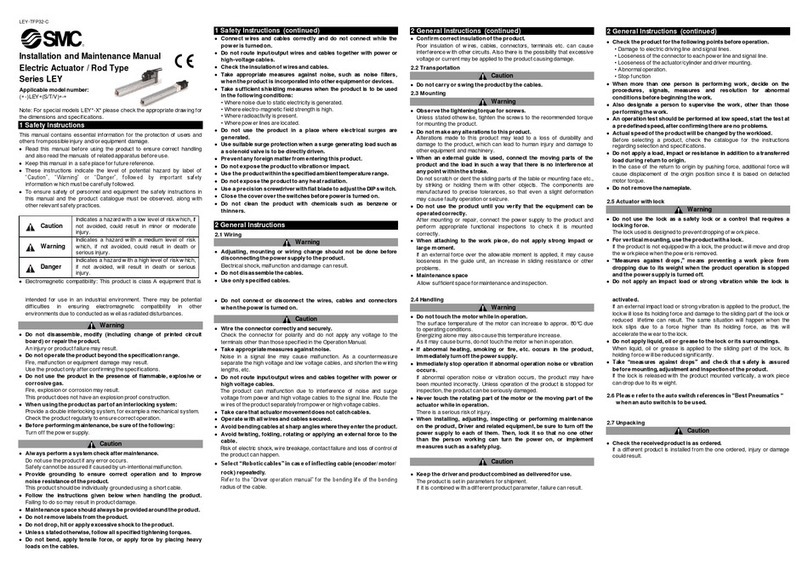

Wiring

Connect the cable to the connector on the main unit as shown in the

following diagram. Take precautions as incorrect wiring will damage the

unit. Use a DC power supply capable of supplying the necessary power

requirements with minimal ripple.

Note: The right angle type connector extends to the left side (over the

supply port side).

Wiring diagram

Setting the Regulator

CAUTION

As soon as the ‘set’ key is operated minimum/maximum pressure will be

present at the outlet port.

CAUTION

As soon as primary pressure is applied to the regulator minimum pressure

will be present at the outlet port.

・Release ‘lock key’ (Fig 1) as explained in section ‘Function of key-lock’

・To set minimum pressure (display shows F-1 Fig 1) use up/down keys

(Fig 1) to set minimum pressure, press ‘set’ key(Fig 1) to ‘lock ’

setting.

・To set maximum pressure(display shows F-2 Fig 1) use up/down keys

(Fig 1) to set maximum pressure, press ‘set’ key(Fig 1) to ‘lock’

setting.

・To set switch output 1 (display shows P-1 Fig 1) use up/down keys to set

switch output, press ‘set’ key(Fig 1) to ‘lock’ setting.

・To set switch output 2 (display shows P-2 Fig 1) use up/down keys to set

switch output.

Note 1:If the above sequence of events has been followed correctly, the

settings will complete automatically.

Note 2:If only setting minimum pressure, when pressure is ‘set’, pressing

the set button once more will ‘skip’ to the next step.

Current signal type Voltage signal type

Vs : Power supply 24VDC

12VDC

A : Input Signal 4 to 20mADC

O to 20mADC

Vs : Power supply 24VDC

12VDC

Vin : Input Signal 0 to 5VDC

O to 10VDC

Fig 6

Function of Key-Lock

With input signal applied

▽Push ‘down’ key (Fig 1) for larger than 2 seconds. Display (a)

flashes ’lock’.

1. Push ‘set’ key (Fig 1) lock automatically releases.

Note: Push ‘down’ key (Fig 1) again to cancel operation.

2. Key Lock Release

1. Push down on ’unlock’ (Fig 1) key for longer than 2 seconds.

2. Key-lock will release.

Note: To cancel push ‘lock’ key (Fig 1).

3. To Lock

1. Push down on ‘up’ △(Fig 1) for longer than 2 seconds.

2. Led will flash ‘unL’ (unlock).

3. Push ‘set’ key (Fig 1) to lock.

Note: To cancel push ‘down’ key (Fig 1).

Function of the ‘Error’ Display

If an abnormality is detected by the ITV2000, 3000, 2090, the LED display

(Fig 1) will show ‘Er’ followed by a code number. Isolate the power supply

and ascertain and solve the problem. Re-instate power supply after

correcting fault.

Error codes are as follows:

Straight Type Connector Right Angle Type Connector

Fig 7

Reset Function

Push up and down keys (Fig 1) together for longer than 3 seconds. Display

(Fig 1) shows ‘RES’. Release keys, minimum, maximum pressures, switch

outputs P1 and P2 are reset to start condition.

CAUTIONS

1. This product (ITV2000, 3000, 2090) is pre-set at the factory and

must not be dismantled by the user. Contact your local SMC office

for advice.

2. Ensure, when installing this product, that is kept clear of power

lines to avoid noise interference.

3. Ensure that load surge protection is fitted when inductive loads are

present (i.e. solenoid, relay etc.).

4. Ensure precautions are in place if the product is used in a ‘free flow

output ’ condition. All will continue to flow continuously.

5. Do not use a lubricator on the input side of this product. If

lubrication is necessary, place the lubricator on the ‘output’ side.

6. Ensure all air is exhausted form the product before maintenance.

7. Length of connector cable shall be 10m or less.

When you enquire about the product, please contact the following

SMC Corporation:

In

B

Blue

load

Black

White

sensor

Brown

M

a

i

n

c

i

r

c

u

i

t

a

PHONE PHONE

ENGLAND 01908-563888 TURKEY 212-2211512

ITALY 02-92711 GERMANY 6103-402-0

HOLLAND 020-5318888 FRANCE 01-64-76-10-00

SWITZERLAND 052-34-0022 SWEDEN 08-603 07 00

SPAIN 945-184100 AUSTRIA 02262-62-280

902-255255 IRELAND 01-4501822

GREECE 01-3426076 DENMARK 87 38 87 00

FINLAND 09-68 10 21 NORWAY 67-12 90 20

BELGUIM 03-3551464 POLAND 48-22-6131847

No Content Display

1 Input Signal Outside Spec. Er 1

2 EEProm Reading / Writing Error Er 2

3 Memory Reading / writing Error Er 3

4 Solenoid Valve Fault Er 4

5 Switch Output Over-Current Er 5