13

© 2011 Somfy SAS. All rights reserved. 09/2011

EN

Please read this installation guide carefully and in full in order to use the products functionalities

to their full extent. Somfy accepts no responsibility for any faults or damage resulting from failure

to adhere to the installation guide (use other than for the intended purpose, incorrect installation,

operating error etc.).

The J4 motor is designed for the electrical control of exterior Venetian blinds.

It is important to follow these instructions for the safety of all persons. Incorrect

assembly can lead to serious injury. These safety instructions must be retained.

The motor, torque and operating time must be adjusted according to the whole installation.

Only original Somfy accessories should be used (adaptors, brackets, same type of cable, etc.).

Fitting, testing, commissioning and repair of the installation must only be carried out by

qualified personnel.

Correct operation of the installation is only guaranteed if the installation and assembly

have been carried out according to best practices, if the power supply is adequate and if

maintenance is carried out.

The moving parts of the motors must be protected if operating below 2.50 m from ground level.

The installation must not be used if it shows any signs of damage (for example wear, damaged

cables/springs or misadjusted end limits).

The installation must be protected from all unauthorised use. Take preventive measures to

avoid any unwanted operation.

Children are not permitted to play with the wired controls. Keep the remote control out of the

reach of children.

Disconnect all connected cables from the power supply before working on the installation.

The permanently installed control points must be visible.

Do not use the installation if work (cleaning windows for example) is being carried out nearby.

Comply with the assembly and operating guides, in particular the safety instructions of the

manufacturer of the device to be used.

Subject to technical modifications.

SOMFY hereby declares that the device complies with the applicable directives.

A declaration of conformity is available at www.somfy.com/ce.

2. General

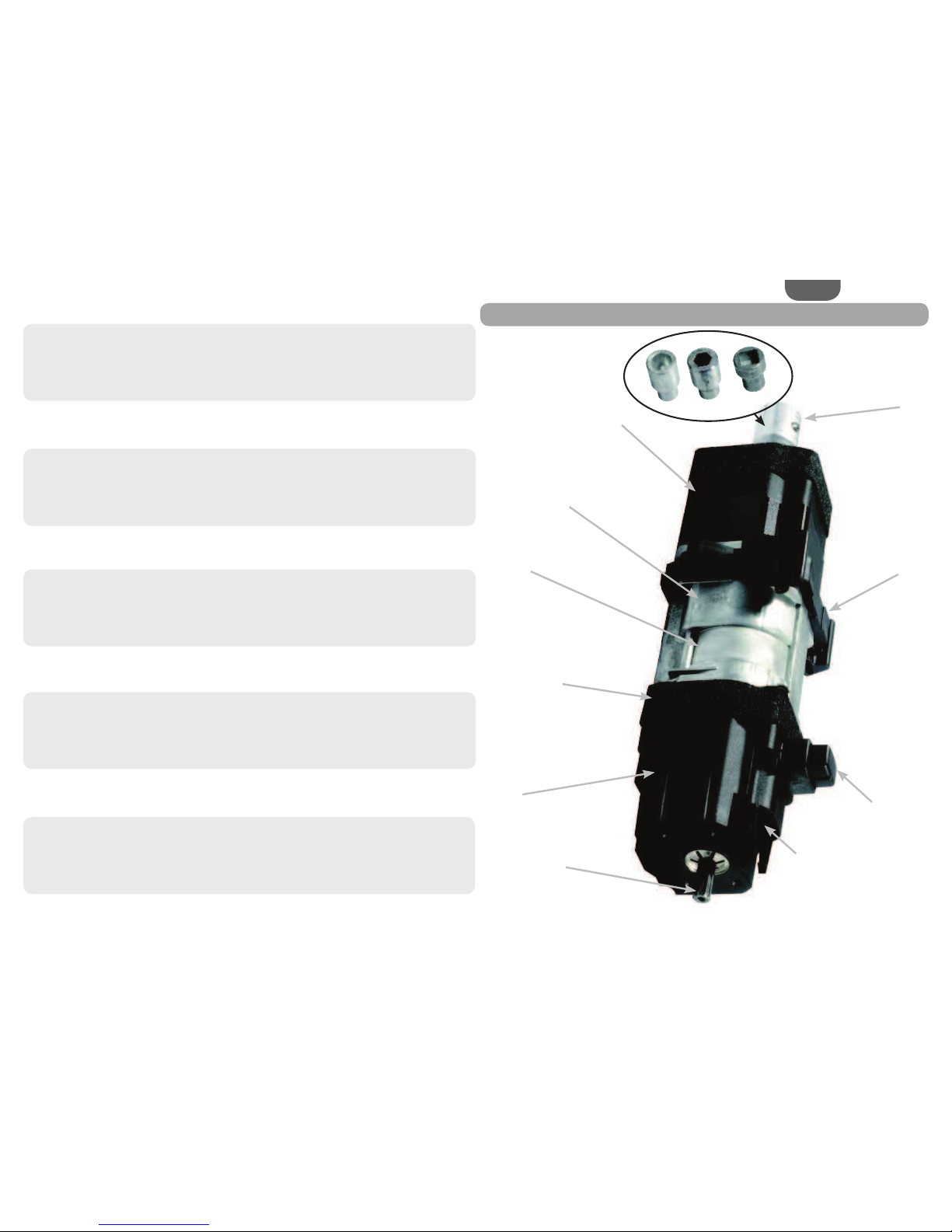

2.3.1. General information

The main function of the mushroom is to ensure the safety of the installer and the end user, by

protecting the motor and the product on which it is installed.

For J4 1TN and J4 2TN motors, the mushroom must be used as an upper end limit.

For J4 HTM and J4 WT motors, the mushroom can be used as an upper end limit if the installer

does not want to adjust this position.

Be sure that during the operation, no slat of the end product exerts radial effort on the mus-

hroom, or the guide tube (if used).

7KHSXOOLQJRXWRIWKHDGMXVWDEOHH[WHQVLRQPDNHVWKHPRWRUXQXVDEOHGH¿QLWLYHO\2.3.2. Options

1TN / 2TN

HTM

2.1. General safety instructions

2.2. Declaration of conformity

2.3. Mushrooms