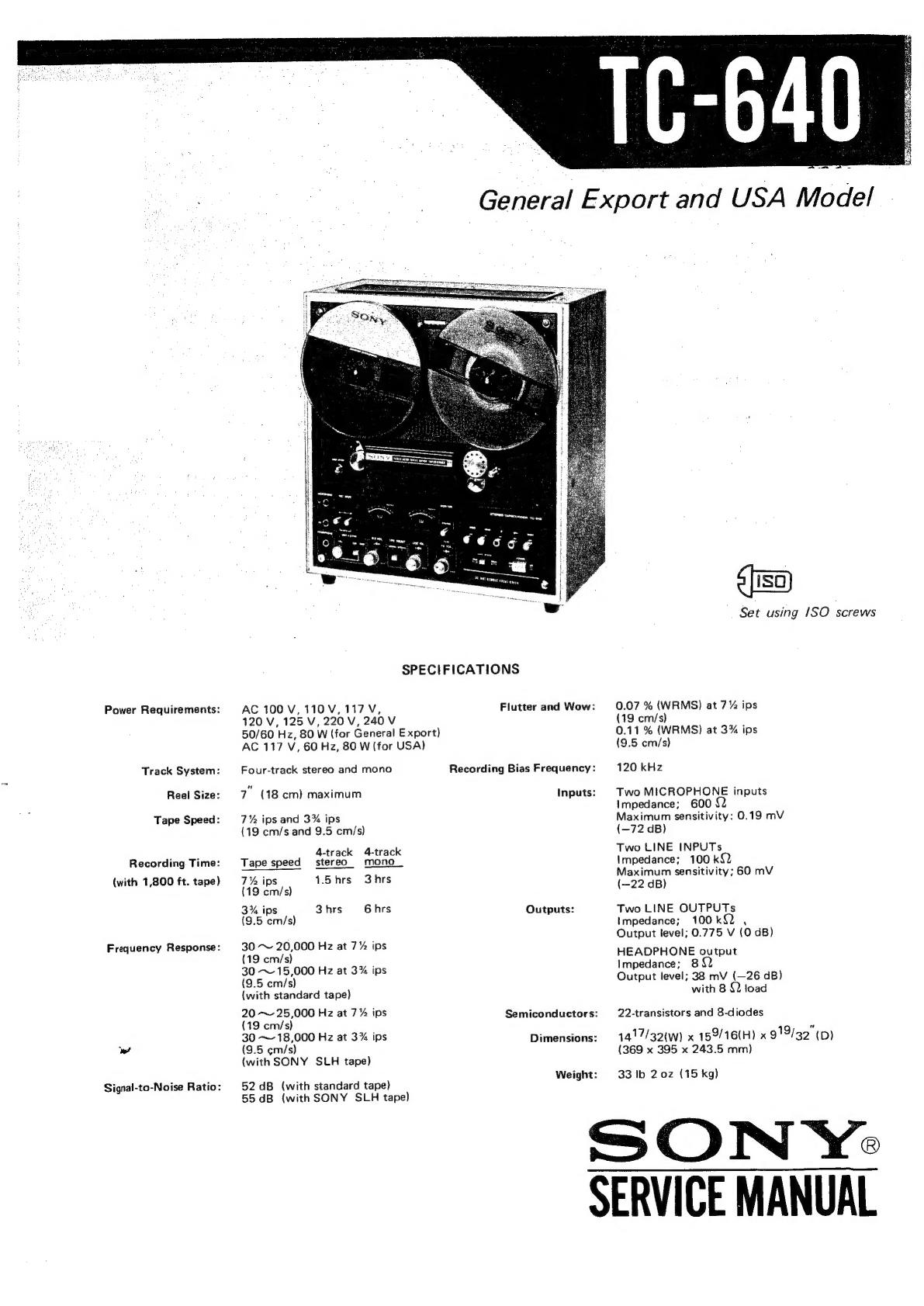

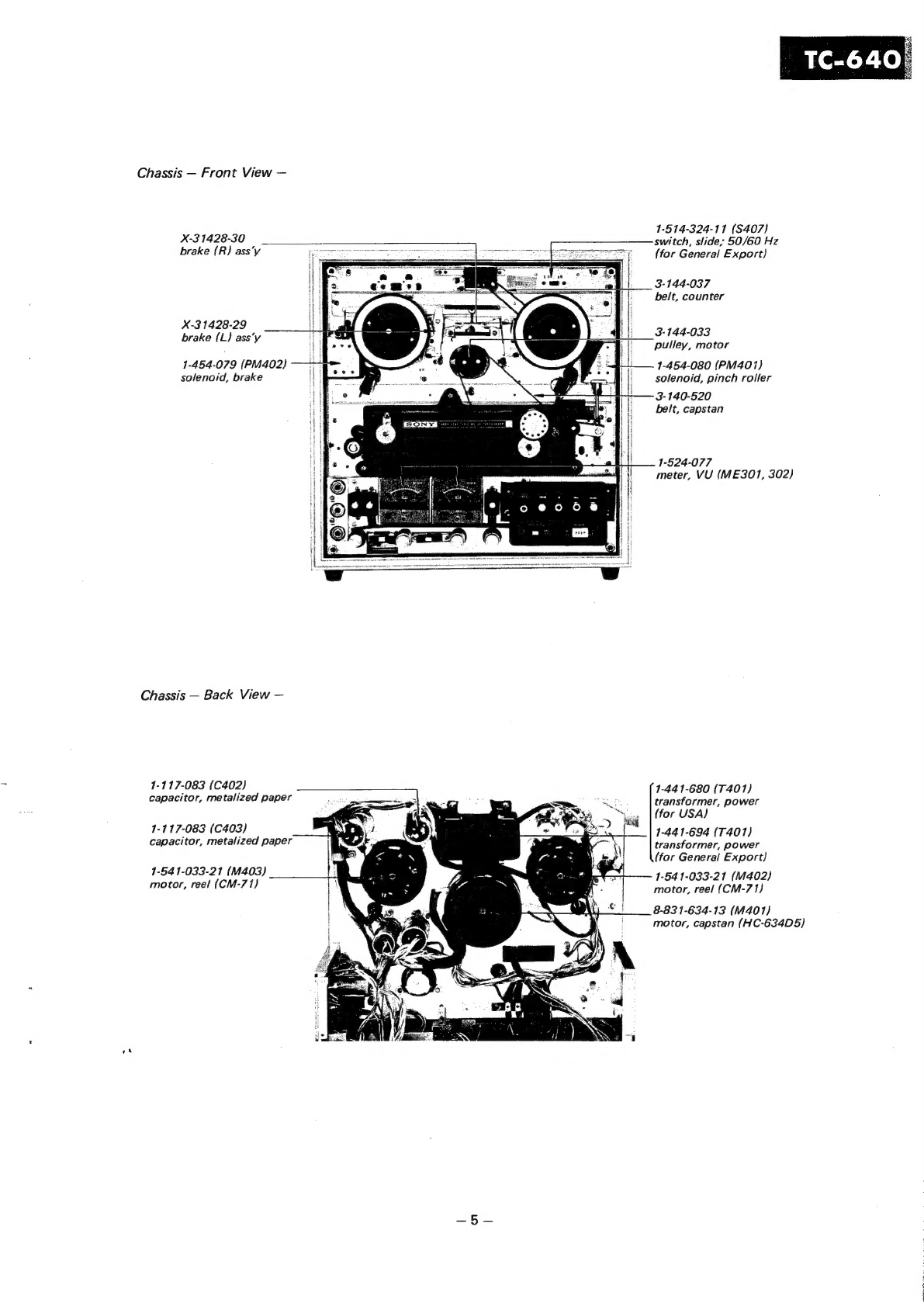

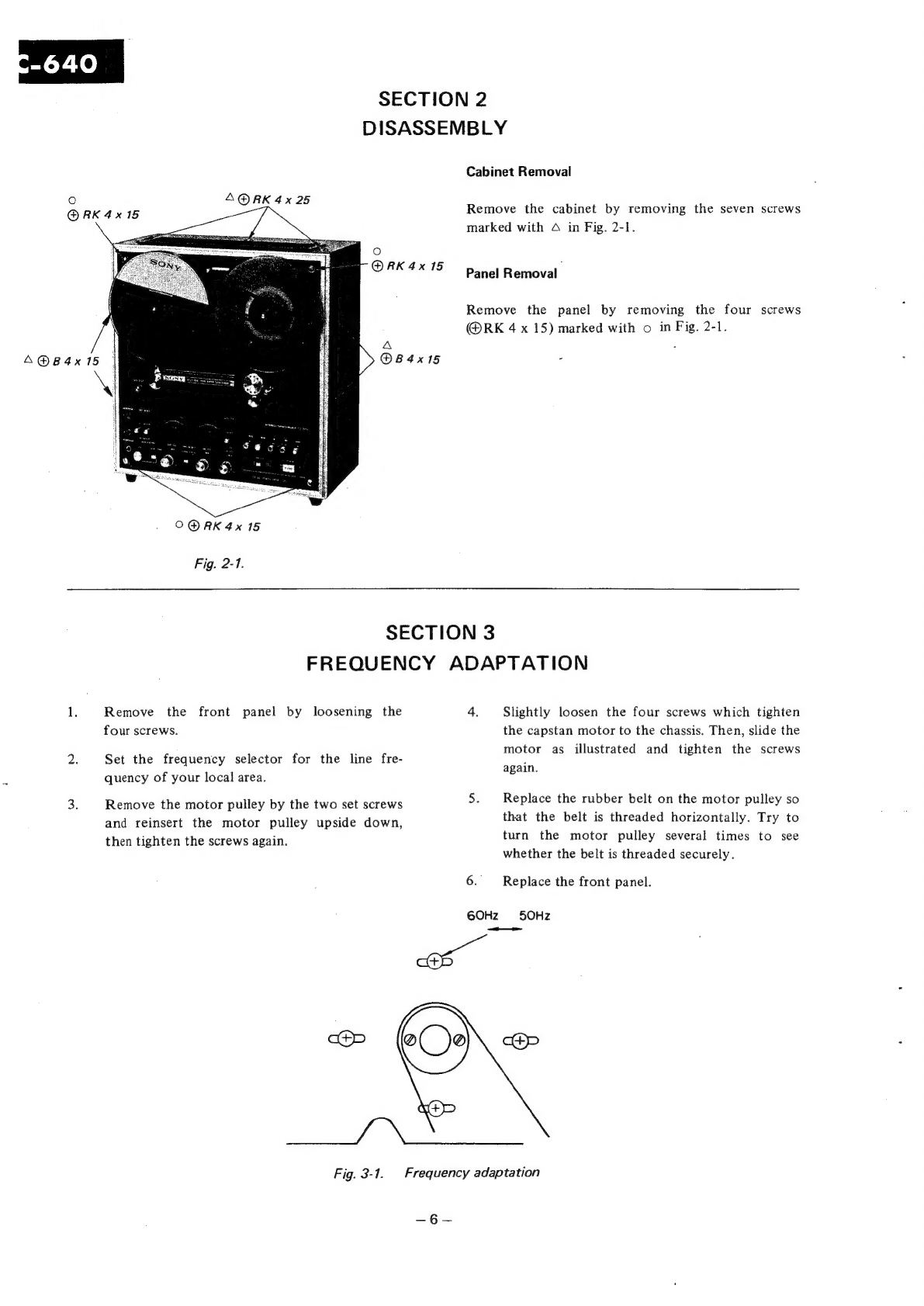

Sony TC-640 User manual

Other Sony Tape Deck manuals

Sony

Sony DTC-57ES User manual

Sony

Sony DTC-ZA5ES User manual

Sony

Sony TC-765 Setup guide

Sony

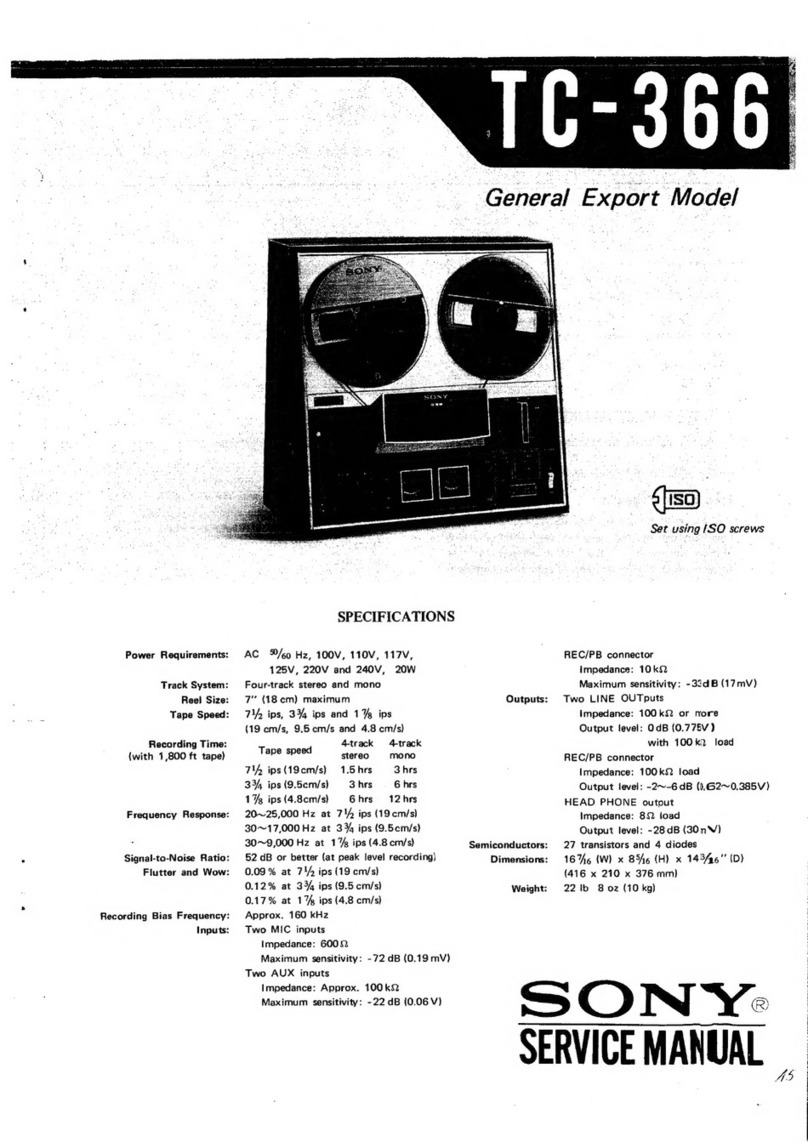

Sony TC-366 User manual

Sony

Sony DTC-77ES User manual

Sony

Sony PCM-R500 - Dat Recorder User manual

Sony

Sony DTC-87ES User manual

Sony

Sony TC-560D Setup guide

Sony

Sony DTC-A6 User manual

Sony

Sony DAT DTC-690 User manual