ST STM32WL Series User manual

Other ST Computer Hardware manuals

ST

ST STM32Cube User manual

ST

ST X-NUCLEO-53L5A1 User manual

ST

ST STEVAL-C34KAT1 User manual

ST

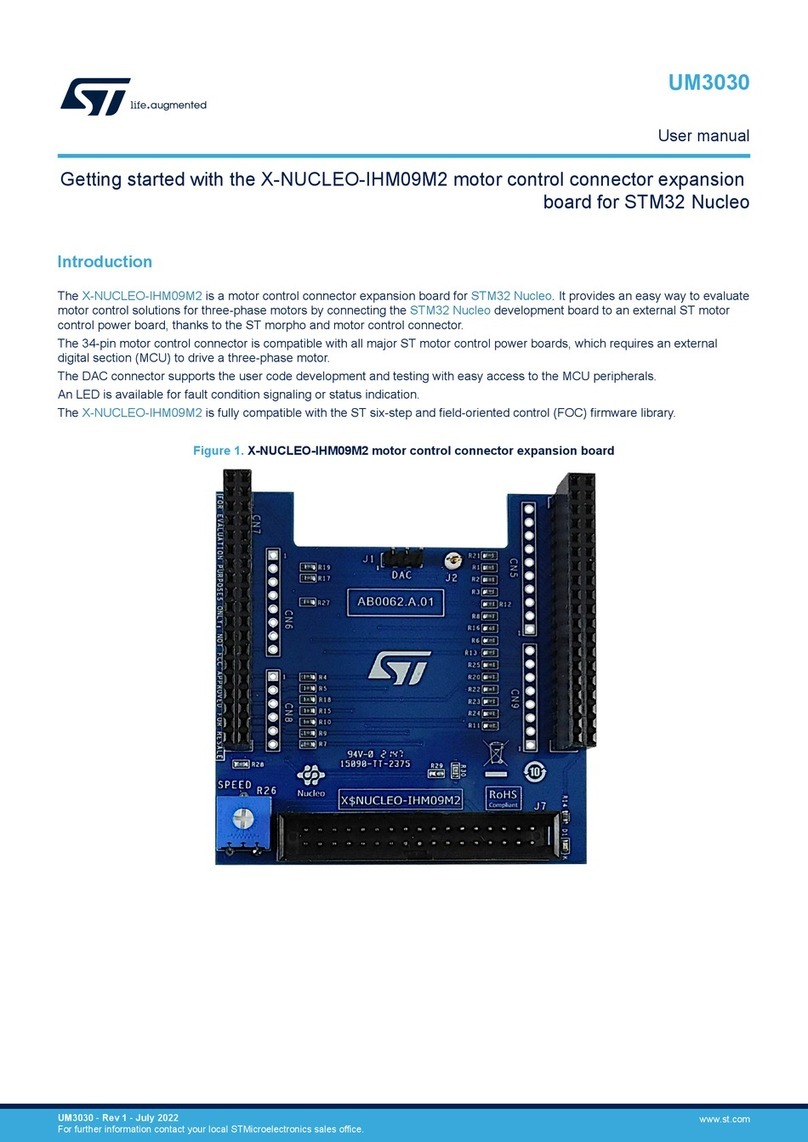

ST X-NUCLEO-IHM09M2 User manual

ST

ST STEVAL-IFP044V1 User manual

ST

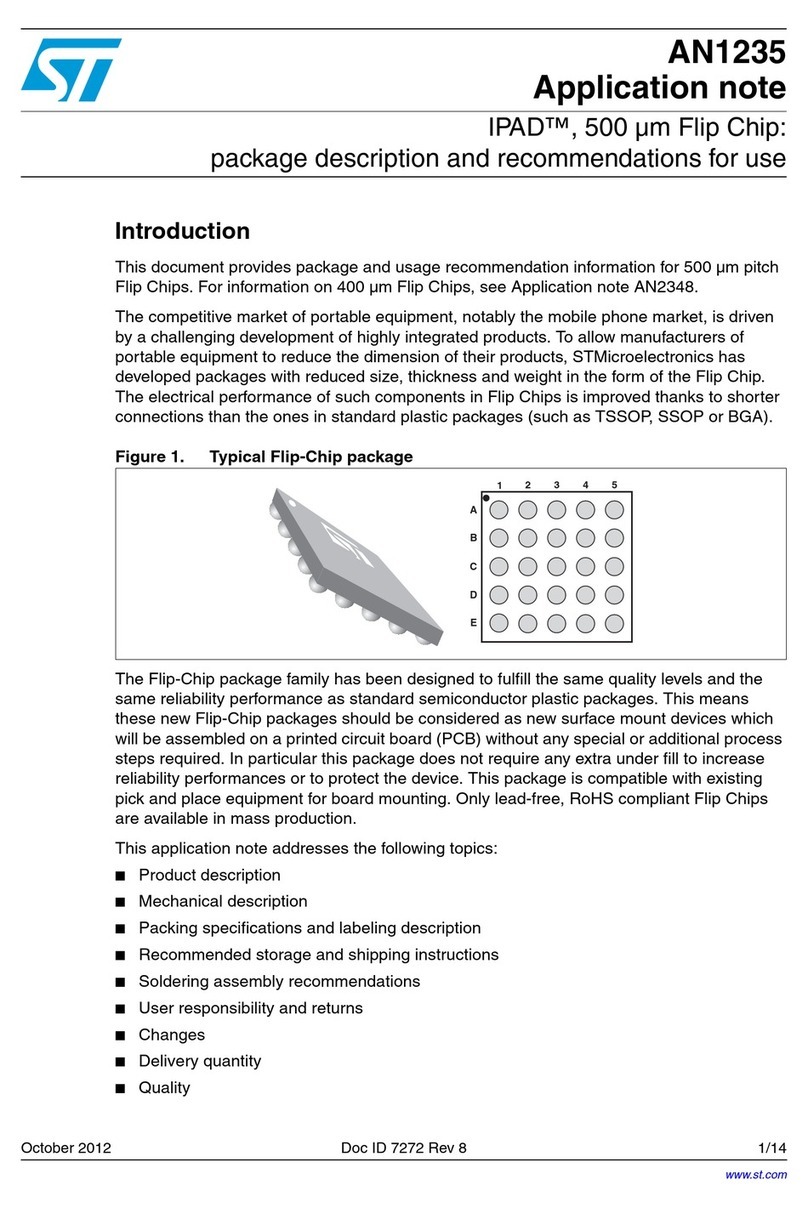

ST AN1235 Installation and operating instructions

ST

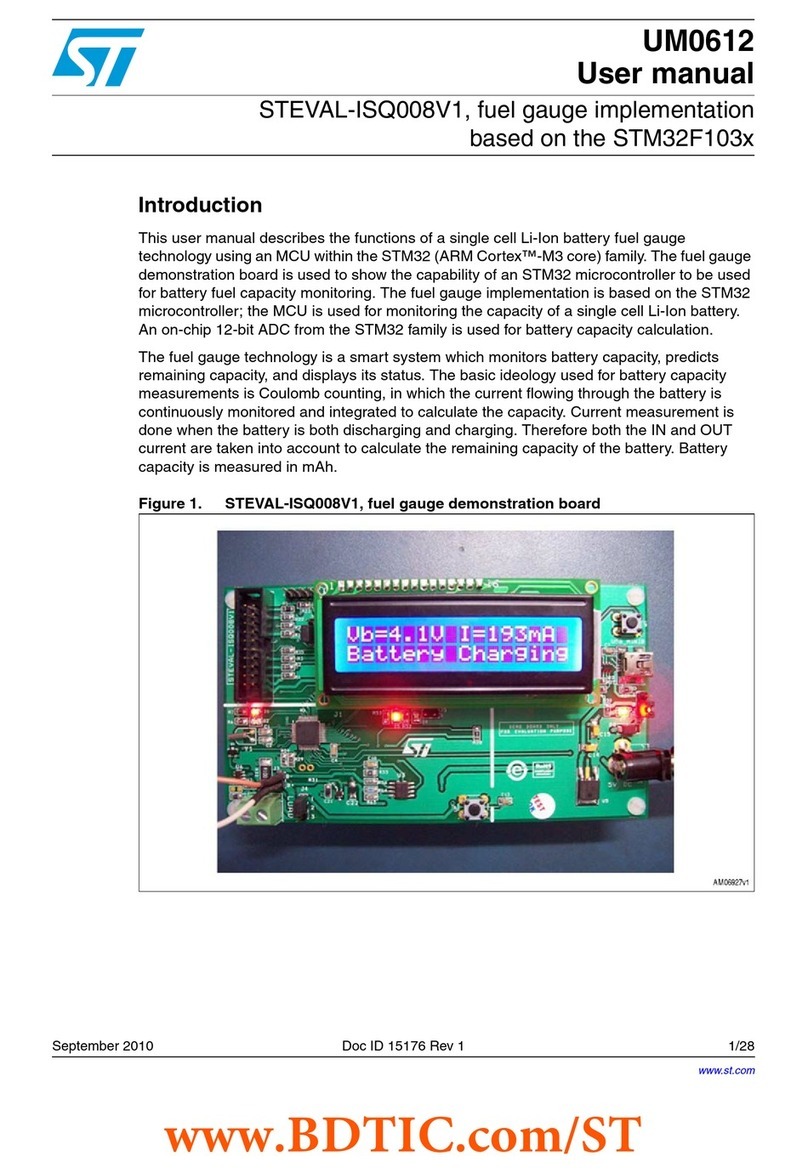

ST STEVAL-ISQ008V1 User manual

ST

ST STM32MP157D-DK1 User manual

ST

ST X-NUCLEO-GNSS1A1 User manual

ST

ST ST92163 User manual

ST

ST X-NUCLEO-OUT06A1 User manual

ST

ST STM32Cube User manual

ST

ST MotionTL User manual

ST

ST X-NUCLEO-S2868A2 User manual

ST

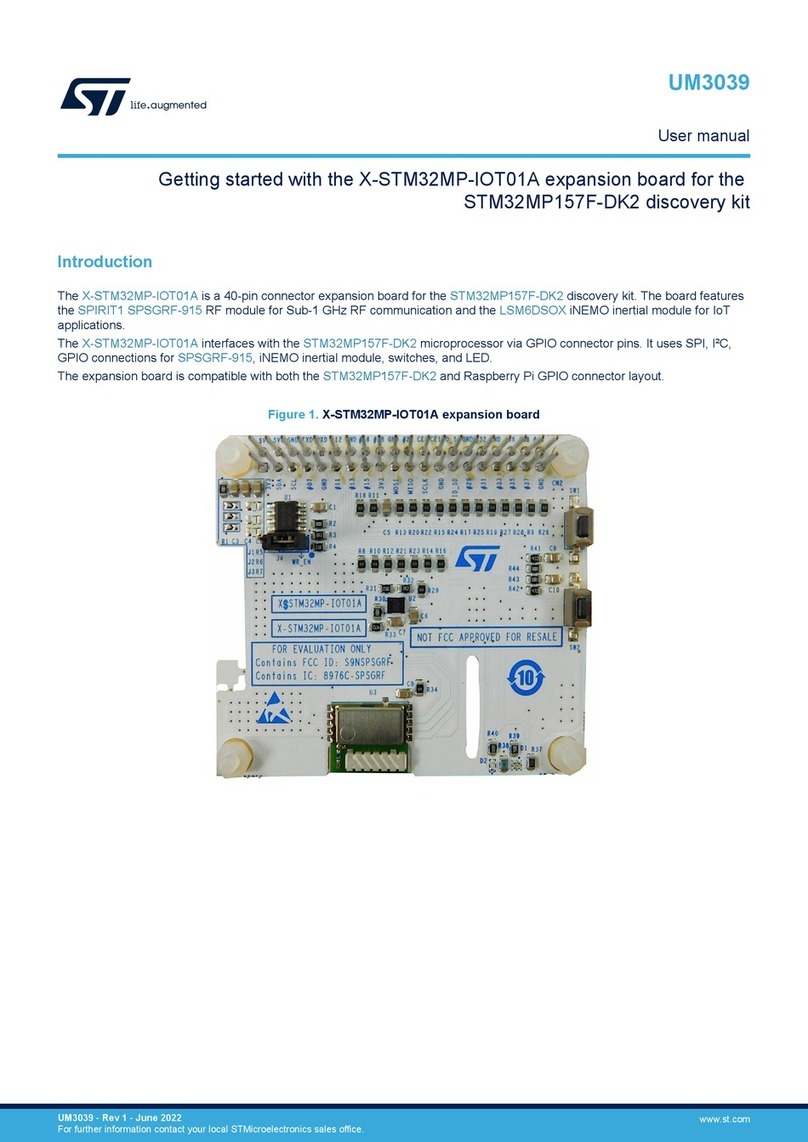

ST UM3039 User manual

ST

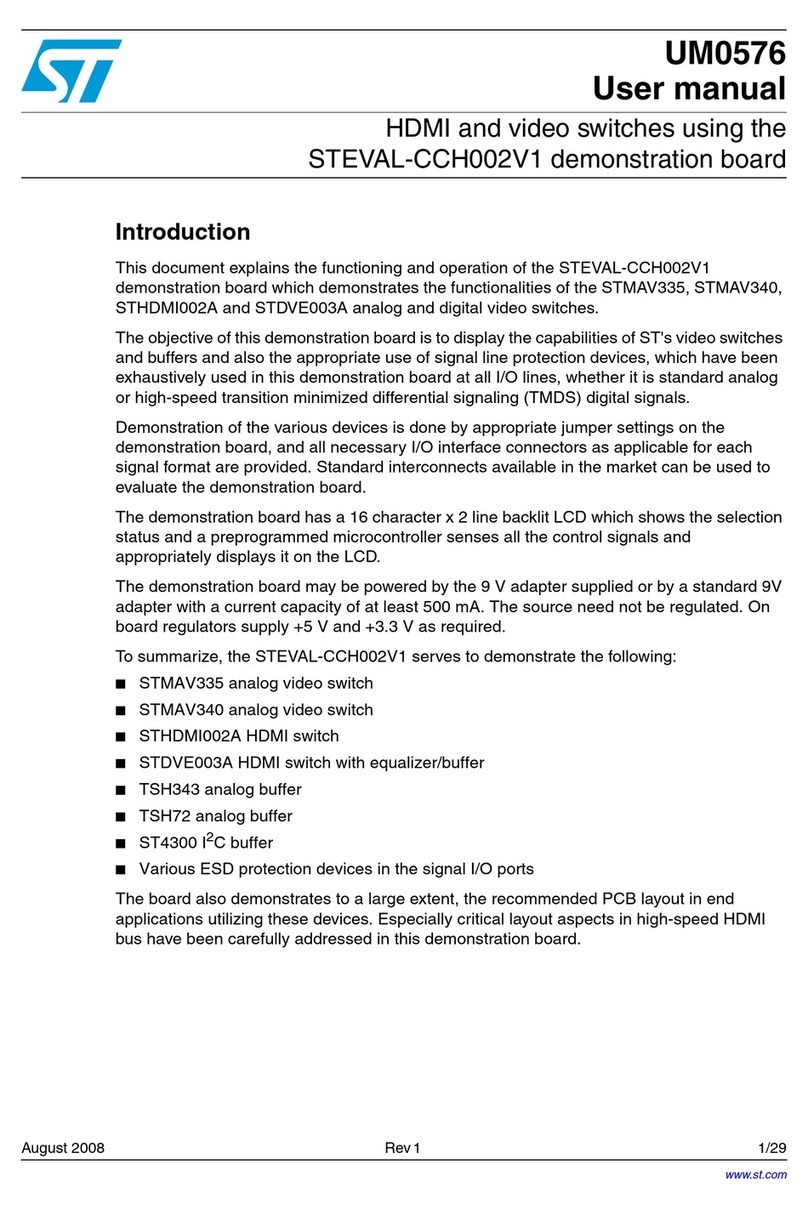

ST STEVAL-CCH002V1 User manual

ST

ST X-NUCLEO-OUT15A1 User manual

ST

ST ZigBee SNDEV-260 User manual

ST

ST X-NUCLEO-53L7A1 User manual

ST

ST METERS AND MORE UM2241 User manual

Popular Computer Hardware manuals by other brands

EMC2

EMC2 VNX Series Hardware Information Guide

Panasonic

Panasonic DV0PM20105 Operation manual

Mitsubishi Electric

Mitsubishi Electric Q81BD-J61BT11 user manual

Gigabyte

Gigabyte B660M DS3H AX DDR4 user manual

Raidon

Raidon iT2300 Quick installation guide

National Instruments

National Instruments PXI-8186 user manual

Intel

Intel AXXRMFBU4 Quick installation user's guide

Kontron

Kontron DIMM-PC/MD product manual

STEINWAY LYNGDORF

STEINWAY LYNGDORF SP-1 installation manual

Advantech

Advantech ASMB-935 Series user manual

Jupiter

Jupiter RAM PACK instructions

Measurement Computing

Measurement Computing CIO-EXP-RTD16 user manual