September 2008 Rev 2 1/40

AN2531

Application note

Generating multicolor light using RGB LEDs

Introduction

The new high power and brightness RGB LEDs are going to be used in many different

lighting applications as backlighting, general lighting systems, traffic signals, automotive

lighting, advertising signs, etc. They are becoming popular mainly because it is possible to

generate an easy multicolor light with special lighting effects and their brightness can be

easy changed. On top of this, their long lifetime and small size make them the light source of

the future.

This document describes how to drive RGB LEDs, how to calculate a power dissipation,

how to design an over temperature protection, how to use a software PWM modulation and

why over voltage protection should be implemented for this kind of application.

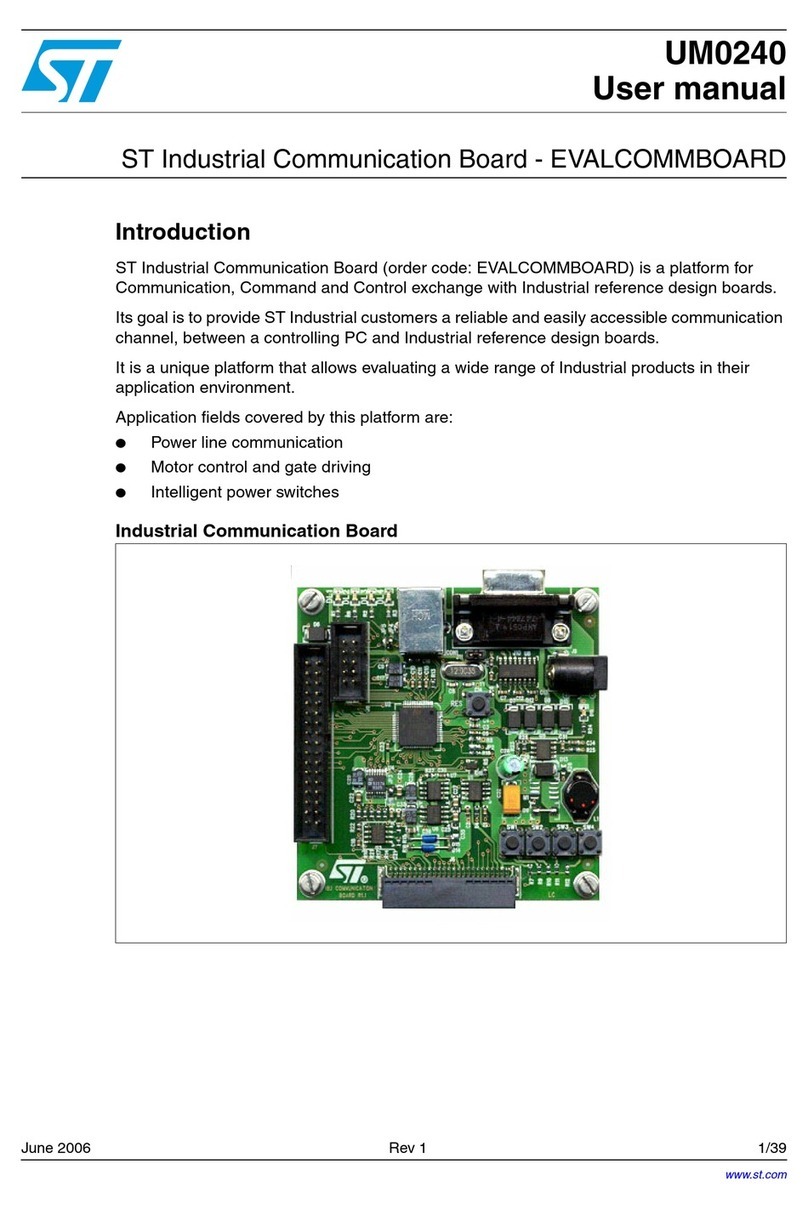

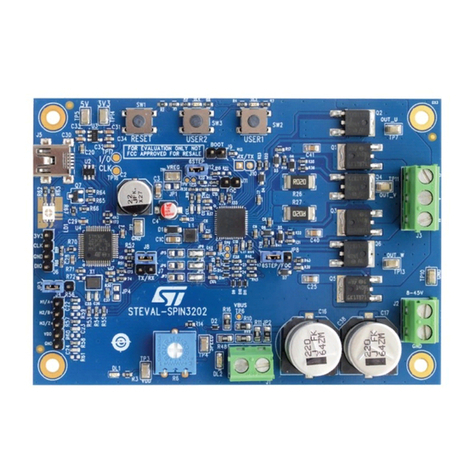

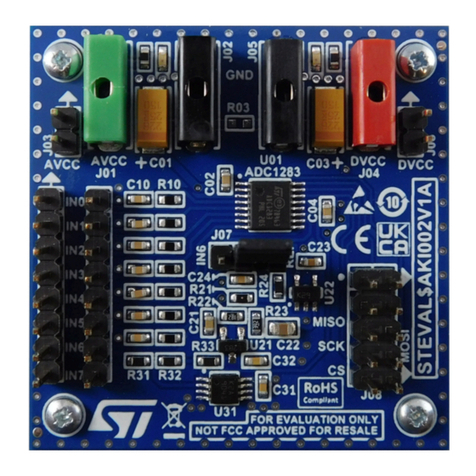

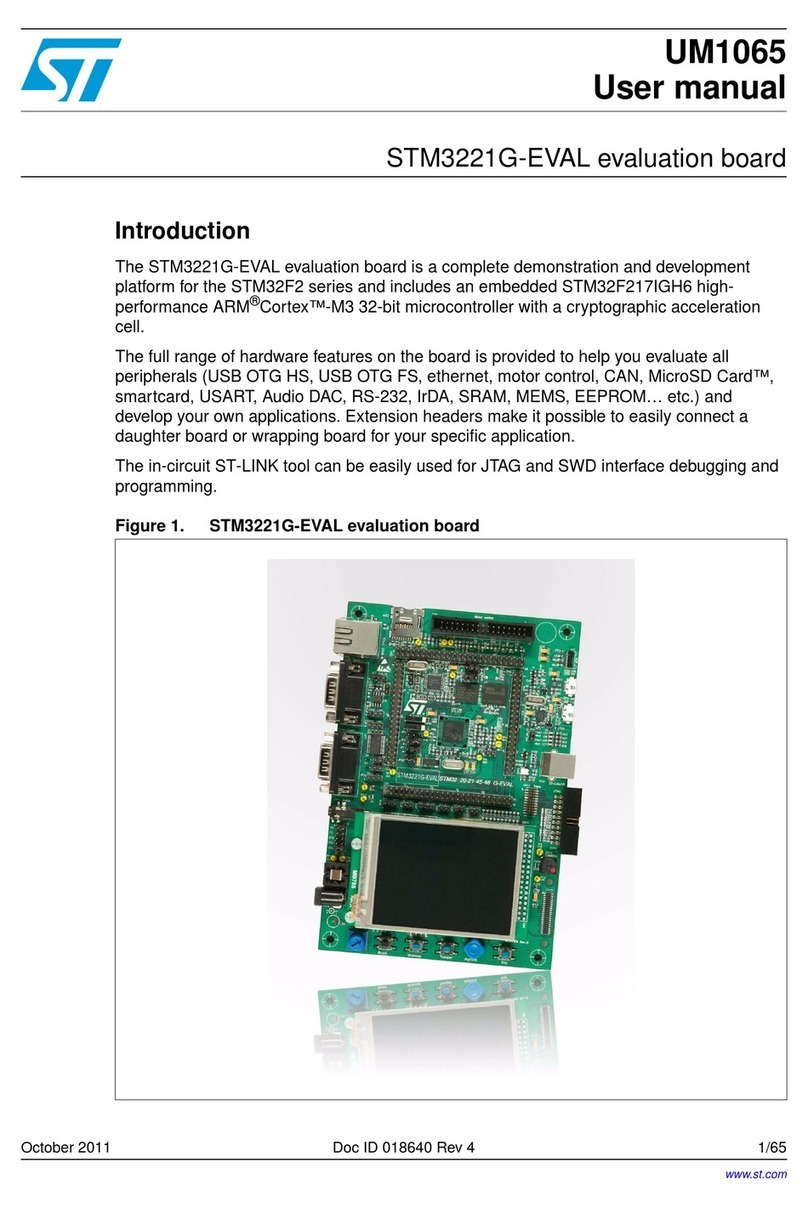

STEVAL-ILL009V1 reference board shown in Figure 1 was developed in order to

demonstrate this design concept. This board was designed for driving super high brightness

multicolor RGB LEDs with current up to 700 mA per LED. The LED brightness and color can

be very easy changed by potentiometers and an automatic color change mode continuously

modulates the color of the LED to generate multicolor light. The LED over temperature

protection is designed on this board and therefore the power delivered to the LED can be

automatically limited to prevent LED overheating.

The STEVAL-ILL009V1 is a mother board assembled without LEDs. To evaluate light effect

features, it is necessary to order a load board (additional board with assembled RGB LEDs).

Two load boards are available for easy performance evaluation. The first one with the

OSTAR

®

Projection Module (refer to Chapter 12, point 1) has ordering code STEVAL-

ILL009V3 and the second one with the Golden DRAGON

®

LEDs (refer to Chapter 12,

point 2) has ordering code STEVAL-ILL009V4. All technical information about these

reference boards such as bill of materials, schematics, software, temperature protection and

so on are described in the sections below.

Note: A new reference board STEVAL-ILL009V5 was designed in order to replace the former

STEVAL-ILL009V1. The main reason why the new board was developed is to demonstrate

a new DC/DC converter capabilities using the ST1S10 and new improved LED drivers

STP04CM05 and STP08CP05. Thanks to the ST1S10 the size of the inductor is extremely

decreased, efficiency improved and board size significantly reduced. The STEVAL-

ILL009V5 reference design is described in Chapter 9.

Figure 1. STEVAL-ILL009V1 reference board

www.st.com