10 - D

DEUTSCH (original)

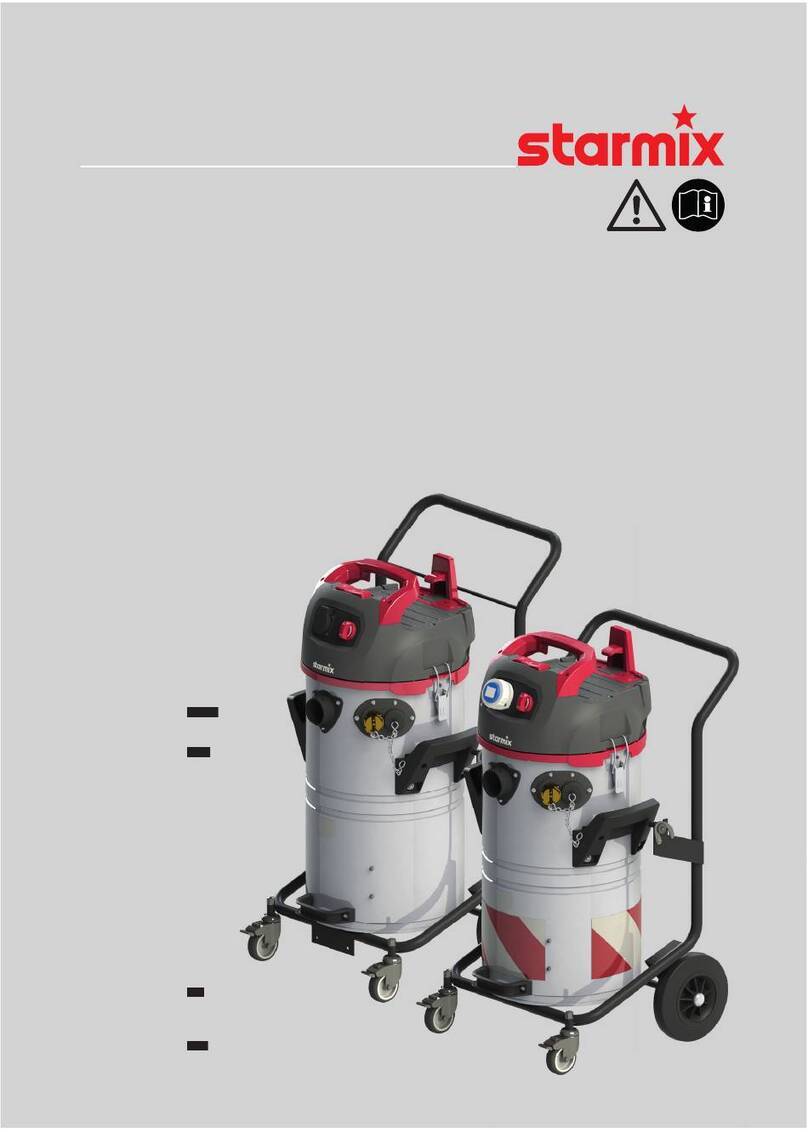

Erzeugnis: Sauger für Nass- und

Trockeneinsatz

Typ:

AS+

Lesen Sie vor der Inbetriebnahme des Saugers die Bedienungsan-

leitung sorgfältig durch. Sie gibt wichtige Hinweise zur Bedienung,

Sicherheit sowie Wartung und Pege. Bewahren Sie die Bedie-

nungsanleitung sorgfältig auf und geben Sie diese bei Veräußerung

an den Nachbesitzer weiter.

Der Hersteller behält sich Konstruktions- und Ausstattungsände-

rungen vor.

Andere Arbeiten, als in dieser Bedienungsanleitung beschrieben,

dürfen Sie nicht ausführen.

Elektrotechnische Prüfungen sind nach den Vorschriften der

Unfallverhütungsvorschrift (BGV A3) und nach DIN VDE 0701 Teil

1 und Teil 3 durchzuführen. Diese Prüfungen sind gemäß DIN VDE

0702 in regelmäßigen Abständen und nach Instandsetzung oder

Änderung erforderlich.

Es ist mindestens jährlich vom Hersteller oder einer unterwiesenen

Person eine staubtechnische Überprüfung durchzuführen, z. B. auf

Beschädigung des Filters, Dichtigkeit des Saugers, Funktion der

Kontrolleinrichtungen.

Die Sauger sind erfolgreich geprüft gemäß IEC/EN 60335–2–69.

1 Vor dem Gebrauch

▶Achten Sie beim Auspacken auf Vollständigkeit und Transport-

schäden.

▶Vor dem Gebrauch sollten die Benutzer mit Informationen, An-

weisungen und Schulungen für den Gebrauch des Saugers und

der Substanzen, für die es benutzt werden soll, einschließlich

des sicheren Verfahrens der Beseitigung des aufgenommenen

Materials, versorgt werden.

2 Verwenden Sie nur Originalzubehör

Siehe Beilagebl

att.

Weiteres Zubehö

r ersehen Sie aus der Sonderzubehörliste bzw.

auf Anfrage.

3 Einsatzbereiche

Zum Nass- und Trockensaugen. Zum Aufsaugen gesundheitsge-

fährlicher Stäube nicht geeignet. Der Sauger mit Steckdose und

Ein-/Ausschaltautomatik ist für den Anschluss von Elektrowerkzeu-

gen vorgesehen.

4 Zusammenbau.

Achten Sie beim Auspacken auf Vollständigkeit und Transport-

schäden.

4.1 Behälter ⑫.

Bei den 20 L- und 32 L-Behältern Rastverschlüsse r öffnen,

Oberteil ①abheben. Behälter umkipppen und Lenkrollen

mit Zapfen ⑰eindrücken bis sie einrasten. Große

Räder ⑮an Achsen ⑯anschrauben s. Abb. A.

Bei den 45 L-Behältern wird die beiliegende Stahlachse ⑯

durch die Führung am Behälter geschoben. Danach werden

die Räder ⑮und Lenkrollen ⑰wie in Abb. B montiert.

Bei den Geräten mit 22 L-, 35 L- und 55 L-Edelstahlbehältern

mit Fahrtraverse werden die Lenkrollen ⑰entsprechend

Abb. C montiert.

Saugrohrhalter ⑳(wenn im Lieferumfang enthalten) von

oben in die Führung am Behälter einsetzen und bis zum

Einrasten nach unten schieben.

4.2 Filter ⑧ - ⑪

Filter anbringen; je nach Modell:

-Faltenlter-Patrone ⑩gerade bis zum Anschlag über das

Gehäuse ⑤führen und den Bajonettverschluss ⑪ verriegeln,

s. Abb. D. Der Faltenlter ist zum Nass- und Trockensaugen

geeignet.

-Schaumstofflter

Zum Wassersaugen Faltenlter vorher abnehmen, Schaumstoff-

lter ⑧über Gehäuse ⑤schieben s.Abb. E.

-Papierlterbeutel ⑱am Flansch fassen und senkrecht

von oben in die Führung der Zyklonsaugöffnung ⑬bis zum

Anschlag aufschieben. Beutel muss an Behälterwand anliegen,

s. Abb. F. Bei Edelstahlbehältern Flansch erst unten und dann

oben auf den Saugstutzen aufstecken und bis zum Anschlag

aufschieben.

-Beutel erhöht Staubrückhaltevermögen und dient der

hygienischen Entsorgung. Papierlterbeutel nur zum

Trockensaugen verwenden.

-Filtersack ⑨in Behälter ⑪einlegen bzw. bei Edelstahlbe-

hältern über den Behälterrand stülpen, s. Abb. G. Filter zum

Nasssaugen herausnehmen.

4.3 Oberteil ①

Motorschutzlter ⑦von Zeit zu Zeit oder bei nachlassender

Saugleistung zum Reinigen herausnehmen, s. Abb. I.

Oberteil ①entsprechend Abb. H seitenrichtig auf Behälter setzen.

Verdrehschutz beachten. Papierlterbeutel ⑱darf nicht beschädigt

werden und Rastverschlüsse ⑭müssen sicher einrasten.

Original-Bedienungsanleitung