Thank you very much for using SUNX products.

Please read this Instruction Manual carefully and

thoroughly for the correct and optimum use of this

product. Kindly keep this manual in a convenient

place for quick reference.

CAUTIONS

2

٨

٨

٨

٨

٨

٨

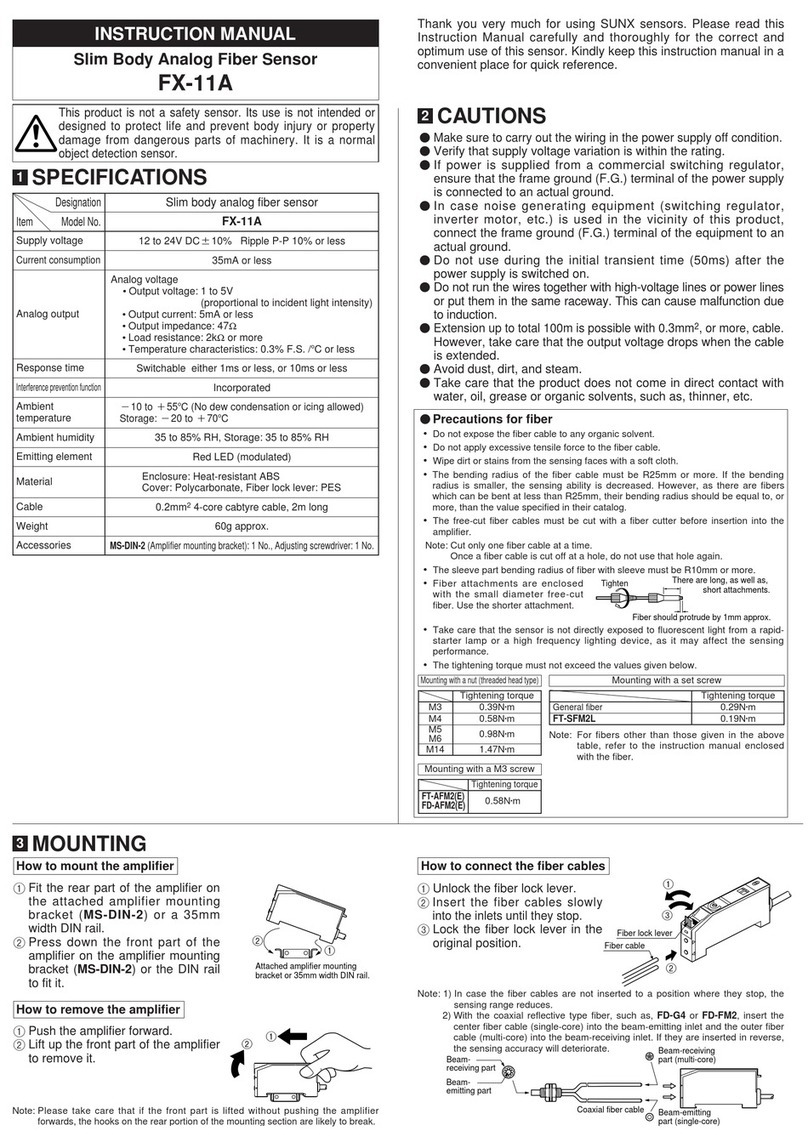

Make sure to carry out wiring in the power sup-

ply off condition.

Take care that wrong wiring will damage the sensor.

Verify that the supply voltage variation is within

the rating.

If power is supplied from a commercial switching

regulator, ensure that the frame ground (F.G.)

terminal of the power supply is connected to an

actual ground.

In case noise generating equipment (switching

regulator, inverter motor, etc.) is used in the vicini-

ty of this product, connect the frame ground (F.G.)

terminal of the equipment to an actual ground.

Do not run the wires together with high-voltage

lines or power lines or put them in the same race-

way. This can cause malfunction due to induction.

٨

٨

٨

٨

٨

٨

٨

٨

Take care that the sensor is not directly exposed to fluo-

rescent lamp from a rapid-starter lamp or a high frequency

lighting device, as it may affect the sensing performance.

Do not use during the initial transient time (50ms)

after the power supply is switched on.

Extension up to total 100m, or less, is possible with

0.3mm2, or more, cable. However, in order to re-

duce noise, make the wiring as short as possible.

Make sure that stress by forcible bend or pulling is

not applied directly to the sensor cable joint.

This sensor is suitable for indoor use only.

Do not use this sensor in places having excessive

vapor, dust, etc., or where it may come in direct

contact with water, or corrosive gas.

Take care that the sensor does not come in direct contact with

water, oil, grease, or organic solvents, such as, thinner, etc.

When connecting the mating cable to the connector type

sensor, the tightening torque should be 0.4N㨯m or less.

INSTRUCTION MANUAL

CX-400 Series

Amplifier Built-in

Photoelectric Sensor

٨

٨

Never use this product as a sensing

device for personnel protection.

In case of using sensing devices for personnel

protection, use products which meet standards,

such as OSHA, ANSI or IEC etc., for personnel

protection applicable in each region or country.

WARNING

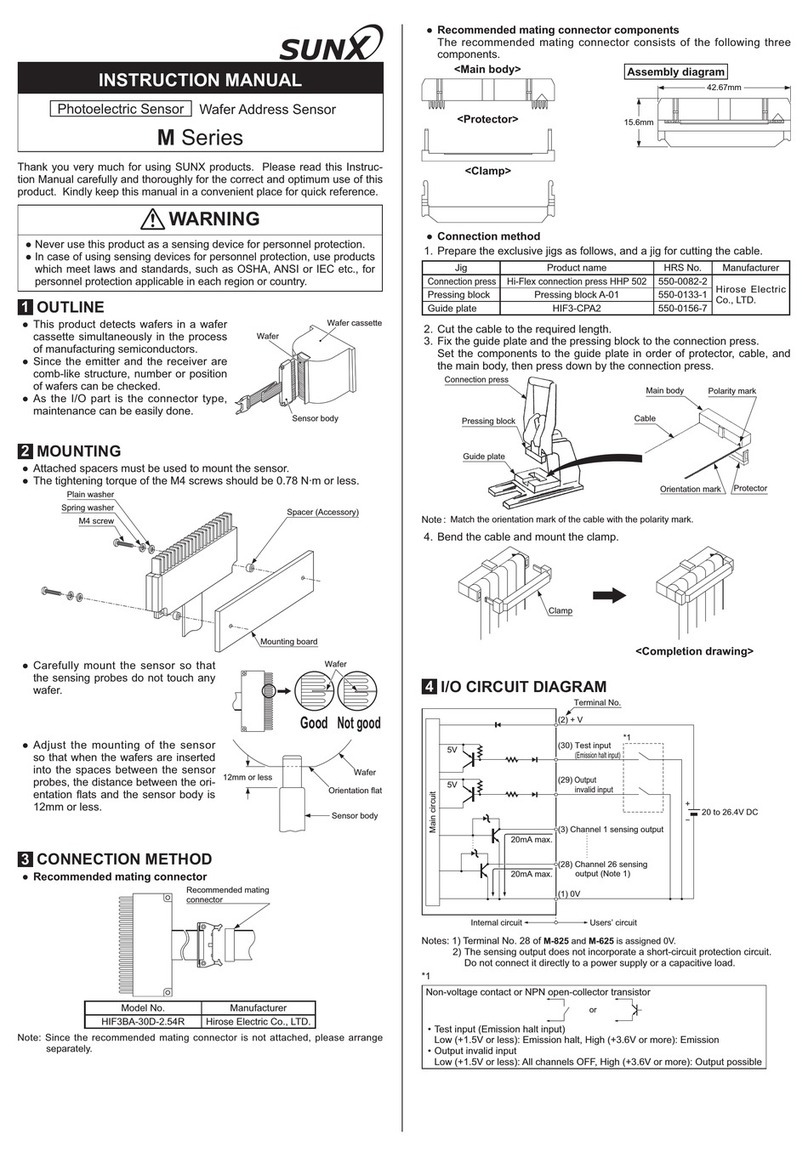

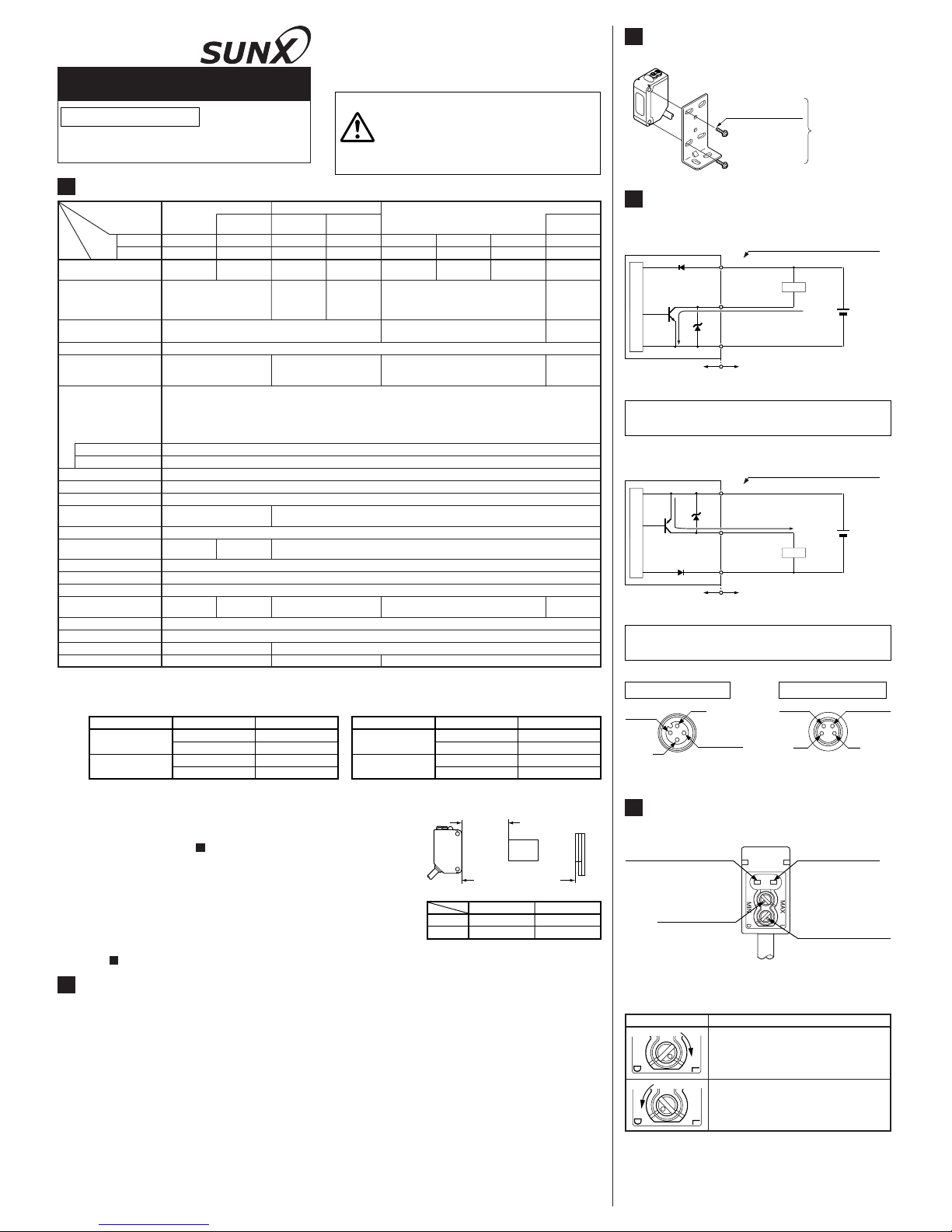

I/O CIRCUIT DIAGRAMS

4

٨Connector pin position of the connector type

M12 pigtailed type

Not con-

nected

2

Output (Note)

㧠

V

1

0V

3

M8 connector type

Not con-

nected

2

Output (Note)

㧠

V

1

0V

3

Note: The thru-beam type sensor emitter does not incorporate the

output.

٨NPN output type

D

TrZD

+

-

12 to 24V DC

r10%

Internal circuit Users' circuit

Load

(Black / 4)

Output(Note)

(Blue / 3)0V

(Brown / 1) +V

Color code / Connector pin No. of

the connector type

100mA max.

Sensor circuit

Note: The thru-beam type sensor emitter does not incorporate the

output.

Symbols...D

ZD

Tr

: Reverse supply polarity protection diode

: Surge absorption zener diode

: NPN output transistor

Note: The thru-beam type sensor emitter does not incorporate the

output.

٨PNP output type

Internal circuit Users' circuit

Color code / Connector pin No. of

the connector type

D

Tr

ZD+

-

12 to 24V DC

r10%

Load

(Black/4)

Output (Note)

(Blue / 3) 0V

(Brown / 1) +V

100mA max.

Sensor circuit

Symbols...D

ZD

Tr

: Reverse supply polarity protection diode

: Surge absorption zener diode

: PNP output transistor

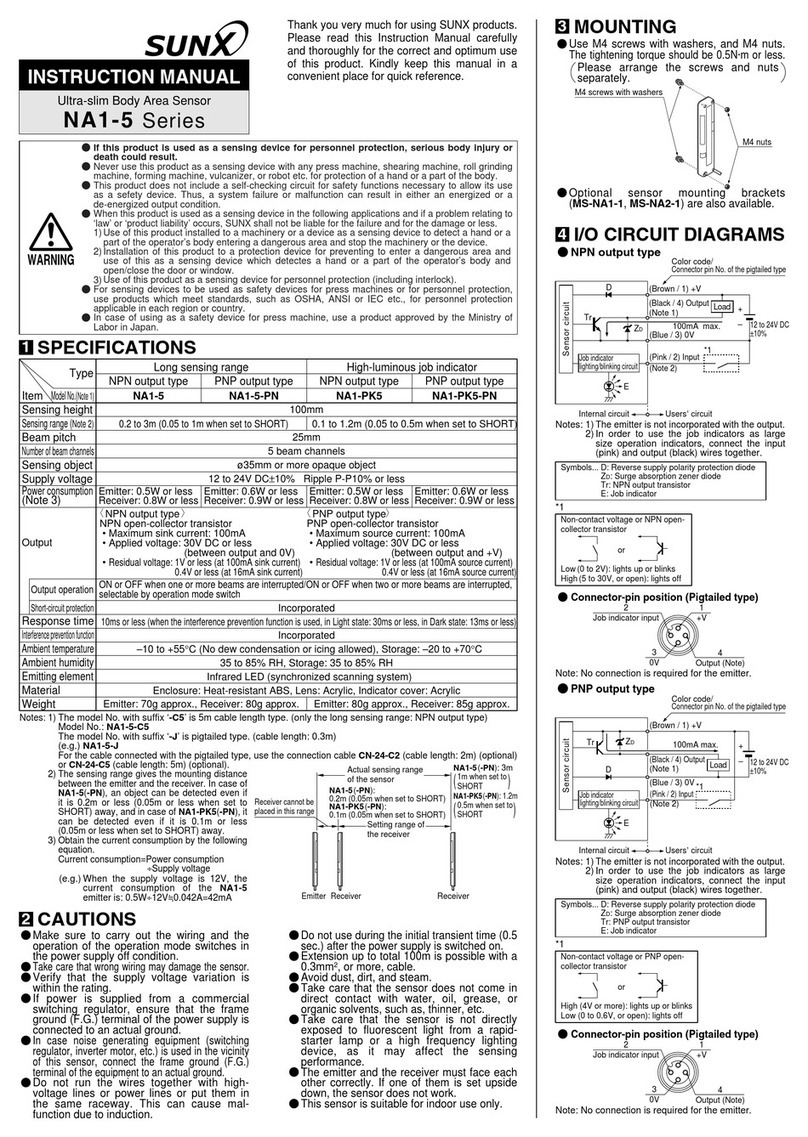

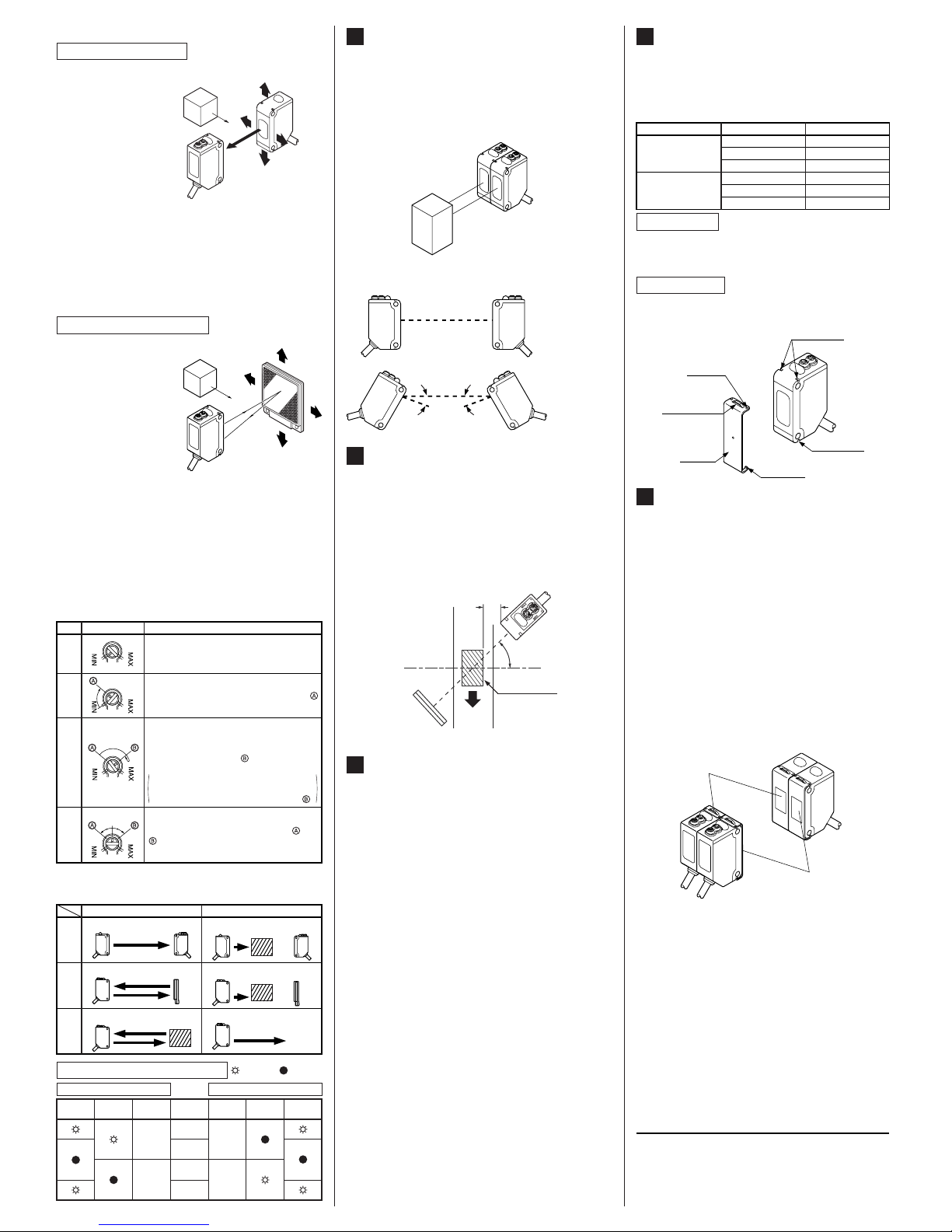

ADJUSTMENTS

5

٨Operation mode switch

Operation mode switch

Description

Light-ON mode is obtained when the opera-

tion mode switch (located on the receiver) is

turned fully clockwise (L side).

Dark-ON mode is obtained when the opera-

tion mode switch (located on the receiver) is

turned fully counterclockwise (D side).

٨Part description

Operation mode switch

(Note 1)

L: Light-ON

D: Dark-ON

Operation indicator

(Orange) (Note 2)

Lights up when the

sensing output is

ON

Sensitivity adjuster

(Note 1)

Sensing range be-

comes longer when

turned clockwise

Stability indicator (Green)

(Note 1)

Lights up under the stable

light condition or the stable

dark condition

Notes: 1)

2)

Not incorporated on the thru-beam type sensor emitter.

It is the power indicator (green: lights up when the power

is ON) for the thru-beam type sensor emitter.

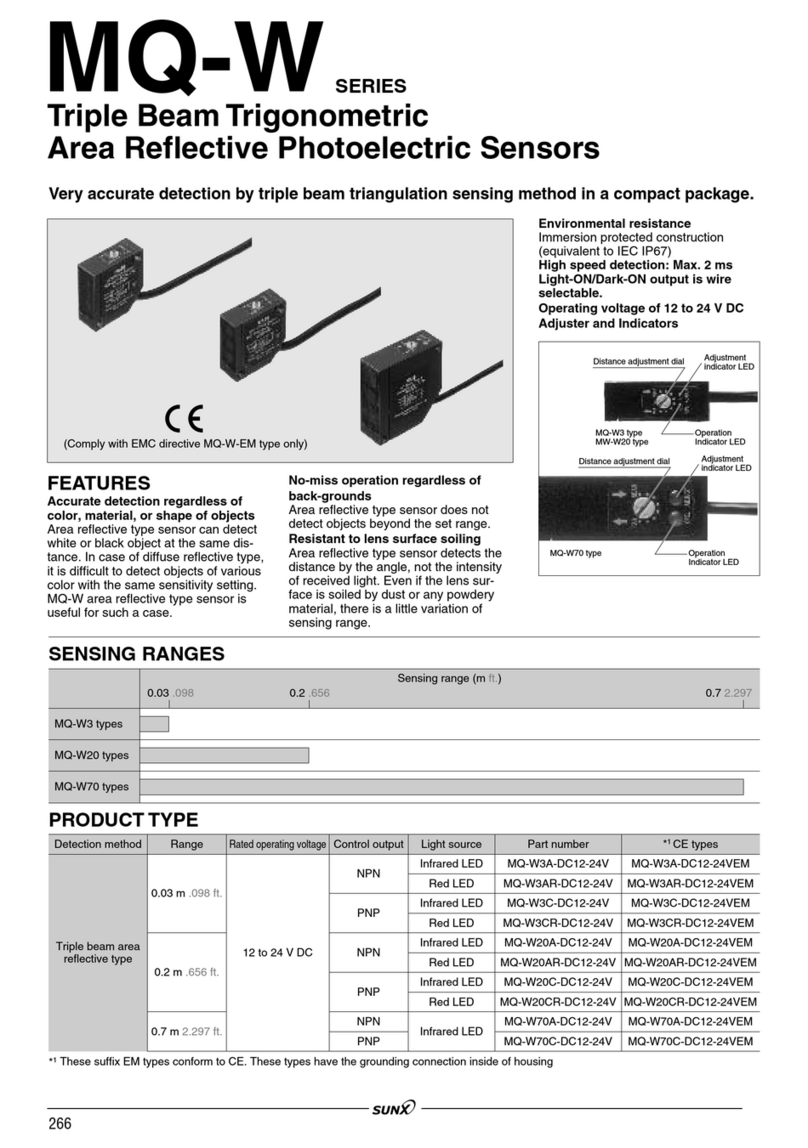

SPECIFICATIONS

1

Automatic interference

prevention function

Long sens-

ing range

70 to 200mm

(Note 4)

800mm

(Note 4)

15m 5m

(Note 3)

300mm

(Note 4)

10m 3m

(Note 3)

100mm

(Note 4)

Sensing range

Narrow-view

CX-422

CX-422-P

CX-423

CX-423-P

CX-412

CX-412-P

CX-491

CX-491-P

CX-493

CX-493-P

CX-424

CX-424-P

CX-421

CX-421-P

CX-411

PNP output

NPN output

Model No.

(Note 1)

CX-411-P

Item

With polarizing

filters (Note 2)

Long sens-

ing range

RetroreflectiveThru-beam Diffuse reflective

Type

20mA or less

25mA or less

12 to 24V DCr10% Ripple P-P 10% or lessSupply voltage

20mA or lessCurrent consumption

Emitter: 20mA or less

(CX-412غ: 25mA or less)

Receiver: 20mA or less

1mmorless

0.5mm or less

0.5mm or less

Repeatability

(perpendicular to sensing axis)

Opaque,

translucent or

transparent

object (Note 5)

Ǿ50mm or

more opaque

or translucent

object (Note 3)

Ǿ12mm or more opaque

object

Ǿ50mm or more

opaque, translu-

cent or specular

object (Note 3)

Opaque, translucent or transparent

object

Sensing object

Infrared LED

(modulated)

0.2mm23-core (thru-beam type sensor emitter: 2-core) cabtyre cable, 2m longCable

Enclosure: PBT, Lens: Acrylic, Indicator cover: Acrylic

Red LED

(modulated)

Red LED

(modulated) Red LED (modulated) Infrared LED (modulated)Emitting element

IP67 (IEC)Protection

-25to+55(No dew condensation or icing allowed), Storage: -30 to +70Ambient temperature

35 to 85% RH, Storage: 35 to 85% RHAmbient humidity

Incorporated (Two units of sensors can be mounted closely.)

Continuously variable adjusterSensitivity adjuster

Green LED (lights up when the

power is ON), located on the emitter

Power indicator

Green LED (lights up under stable light received condition or stable dark condition), thru-beam type sensor: located on the receiver

Stability indicator

Orange LED (lights up when the output is ON), thru-beam type sensor: located on the receiverOperation indicator

1ms or less

㧙

㧙

㧙㧙

㧙

(Note 6)

Response time

Switchable either Light-ON or Dark-ON

Incorporated

Output

Output operation

Short-circuit protection

<NPN output type>

NPN open-collector transistor

Maximum sink current: 100mA

Applied voltage: 30V DC or less (between output and 0V)

Residual voltage: 1V or less (at 100mA sink current)

0.4V or less (at 16mA sink current)

<PNP output type>

PNP open-collector transistor

Maximum source current: 100mA

Applied voltage: 30V DC or less (between output and +V)

Residual voltage: 1V or less (at 100mA source current)

0.4V or less (at 16mA source current)

RF-230 (Reflector): 1 pc.

Material

50g approx.

Emitter: 45g approx., Receiver: 50g approx.

Weight

Accessory

Notes: 1) The model No. with suffix '-J' is the M12 pigtailed type, '-Z' is the M8 connector type.

(e.g.) M12 pigtailed type: CX-411-J, M8 connector type: CX-411-Z

Use the connection cables as shown below. (Two sets are required for the thru-beam type sensor.)

<Connection cable for the M12 pigtailed type>

Type Model No. Cable length

2-core type CN-22-C2 2m

CN-22-C5 5m

4-core type CN-24-C2 2m

CN-24-C5 5m

<Connection cable for the M8 connector type>

Type Model No. Cable length

Straight type CN-24A-C2 2m

CN-24A-C5 5m

Elbow type CN-24AL-C2 2m

CN-24AL-C5 5m

2)

3)

4)

5)

6)

The model No. with suffix 'E' shown on the label affixed to the thru-beam type sensor is the emitter, 'D' shown on the label is the receiver.

Thru-beam type sensor emitter: CX-41غE, Thru-beam type sensor receiver: CX-41غD

The model No. of retroreflective type sensor with the suffix '-Y' is the sensor without the RF-230 reflector.

(e.g.) CX-491-Y

The retroreflective type sensor with polarizing filters may not stably detect specular

or glossy objects through transparent film since light is polarized by the transparent

film. For details, refer to ' RETROREFLECTIVE TYPE SENSOR WITH POLAR-

IZING FILTERS'.

The sensing range and the sensing object of the retroreflective type sensor is specified

fot the RF-230 reflector. The sensing range represents the actual sensing range of the

sensor. The sensing ranges itemized in 'A' of the table below may vary depending of the

shape of sensing object. Be sure to check the operation with the actual sensing object.

The sensing range of the diffuse reflective type sensor is specified for white non-

glossy paper (200 200mm) as the object.

The minimum sensing object of the diffuse reflectivenarrow-view type sensor is

Ǿ0.5mm copper wire.

By mounting interference prevention filters (PF-CX4-غ), two sets of the sensor can be mounted close together. For details, refer

to ' INTERFERENCE PREVENTION FILTER (OPTIONAL)'.

8

10

Sensing range

(A)

Reflector setting range

(B)

Sensor Reflector

Sensing

object

A

B

3m

0.1 to 3m

5m

0.1to5m

CX-491غCX-493غ

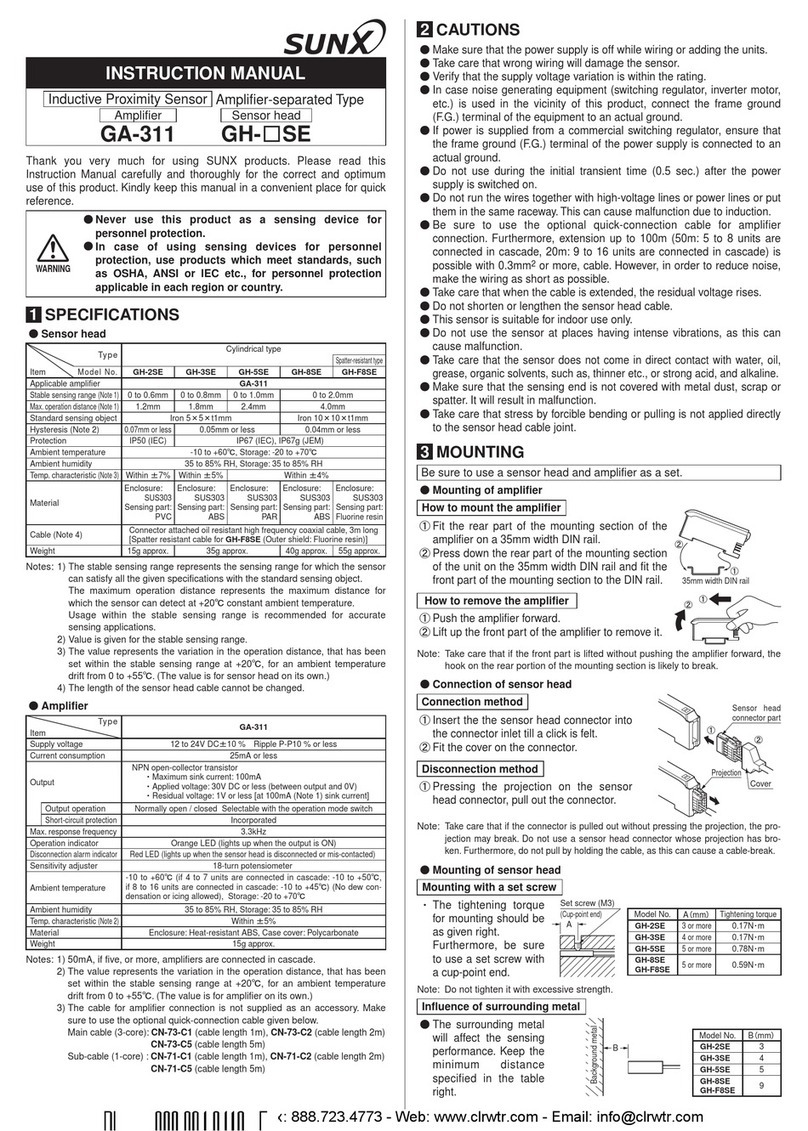

MOUNTING

3

٨The tightening torque should be 0.5N㨯m or less.

Sensor mounting

bracket

(Optional)

M3 (length 12mm)

screw with washers