NA2-N Series

Slim Body Area Sensor

This product is not a safety sensor. Its use is not intended or

designed to protect life and prevent body injury or property

damage from dangerous parts of machinery. It is a normal

object detection sensor.

This sensor is not for press machine safeguard. Do not use this

sensor for any press machine. For area sensors conforming to

safety standards, please contact our office.

Thank you very much for using SUNX sensors. Please read this Instruction

Manual carefully and thoroughly for the correct and optimum use of this

sensor. Kindly keep this manual in a convenient place for quick reference.

INSTRUCTION MANUAL

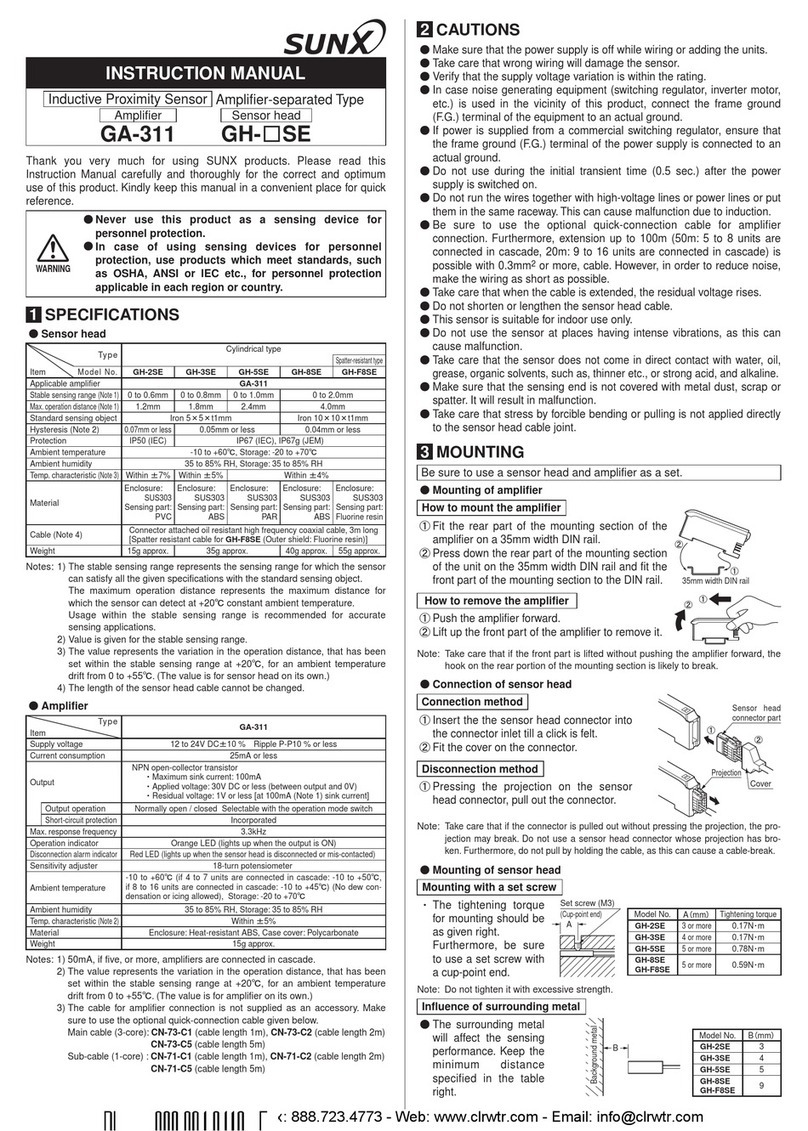

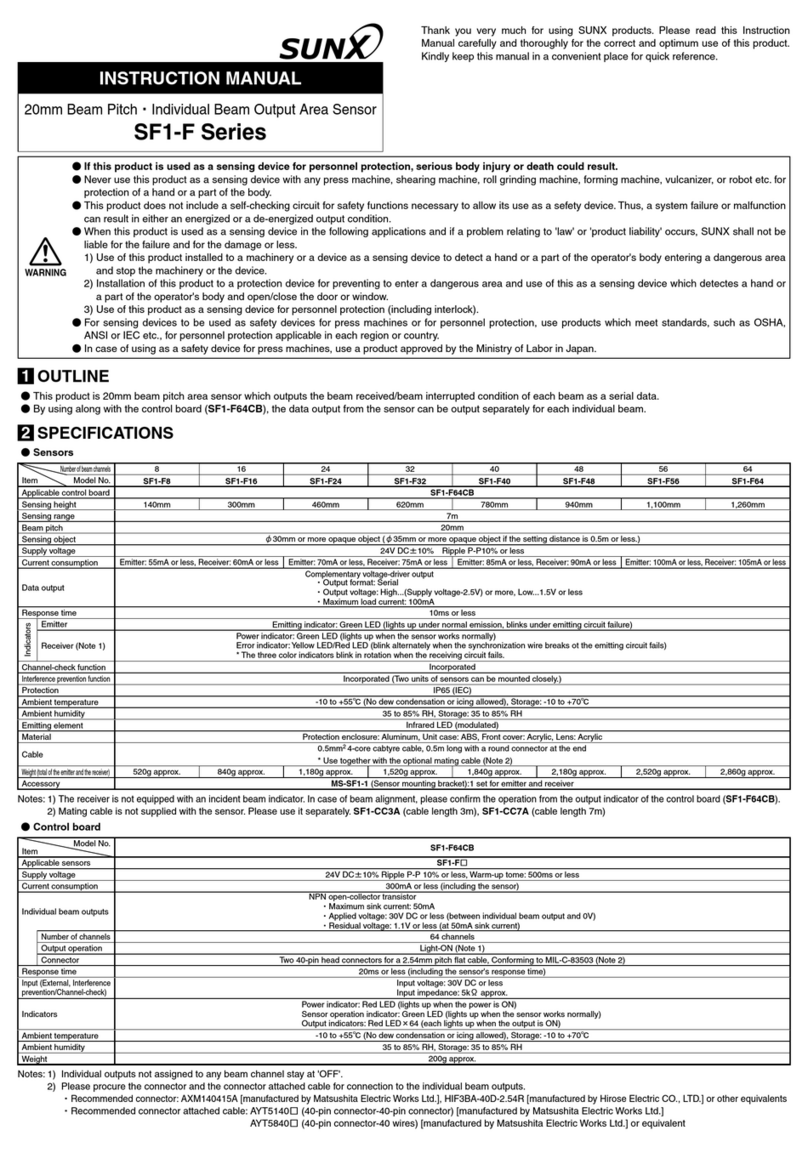

Number of

beam channels

Item

Model No.

PNP output

NPN output

8

NA2-N8-PN

NA2-N8

12

NA2-N12-PN

NA2-N12

16

NA2-N16-PN

NA2-N16

20

NA2-N20-PN

NA2-N20

24

NA2-N24-PN

NA2-N24

28

140mm

Power consumption

Indicators

Emitter

Receiver

220mm 300mm 380mm

5m

20mm

30mm or more opaque object

NPN open-collector transistor

Maximum sink current: 100mA

Applied voltage: 30V DC or less

(between output and 0V)

Residual voltage: 1V or less

(at 100mA sink current)

0.4V or less

(at 16mA sink current)

PNP open-collector transistor

Maximum source current: 100mA

Applied voltage: 30V DC or less

(between output and +V)

Residual voltage: 1V or less

(at 100mA source current)

0.4V or less

(at 16mA source current)

12 to 24V DC 10% Ripple P-P 10% or less

460mm 540mm

0.5W or less 0.5W or less 0.6W or less 0.6W or less 0.7W or less 0.7W or less

0.4W or less 0.4W or less 0.5W or less 0.5W or less 0.6W or less 0.6W or less

0.7W or less 0.8W or less 0.9W or less 1.0W or less 1.1W or less 1.2W or less

0.6W or less 0.7W or less 0.8W or less 0.9W or less

ON when all beams are received (OFF when one or more beams are interrupted)

Incorporated

10 to 55 (No dew condensation or icing allowed), Storage: 10 to 60

10ms or less (12ms or less when the interference prevention function is used)

1.0W or less 1.1W or less

350g approx. 400g approx. 450g approx. 500g approx. 550g approx. 600g approx.

NA2-N28-PN

NA2-N28

Sensing height

Sensing range

Beam pitch

Sensing object

Supply voltage

Output

Response time

Ambient temperature

35 to 85% RH, Storage: 35 to 85% RH

Ambient humidity

Infrared LED (modulated)

Emitting element

Enclosure: Heat-resistant ABS, Front cover: Polyacetal, Indicator cover: Acrylic

Material

0.2mm24-core oil-resistant cabtyre cable, 3m long

Cable

Weight

Output operation

Emitter

Receiver

Short-circuit protection

Job indicator ON

Job indicator OFF

Job indicator ON

Job indicator OFF

Emitting indicator: Green LED 2 (light up when the power is ON;

one LED lights up for Frequency A setting,

both LEDs light up for Frequency B setting)

Job indicator: Red LED (lights up, blinks or lights off when the job indicator

input is applied, selected by operation mode switch)

NPN output type PNP output type

Operation indicator:

Stable incident beam indicator:

Job indicator:

Red LED (lights up when one or more beams are interrupted)

Green LED (lights up when all beams

are stably received)

Red LED (lights up, blinks or lights off when the job indicator

input is applied, selected by operation mode switch)

When an excess current flows through the output, the stable

incident beam indicator and the operation indicator on the

receiver blink simultaneously due to the operation of the short-

circuit protection circuit.

Use M4 screws with washers and M4 nuts. The

tightening torque should be 0.5N.m or less.

During mounting, do not apply any bending or

twisting force to the sensor. (Please arrange the

screws and nuts separately.)

Sensor mounting brackets (MS-NA2-1, MS-NA1-1)

are also available.

M4 screws with washers

M4 nuts

MS-NA2-1 assembly drawing MS-NA1-1 assembly drawing

In case of rear-side mounting

M4 screw

with washers

Anti-rotation hook

Sensor mounting bracket

nut

M4 screw

with washers

Anti-rotation hook

Sensor mounting bracket

nut

Make sure to carry out the wiring in the power supply off condition.

Verify that the supply voltage variation is within the rating.

If power is supplied from a commercial switching regulator, ensure that

the frame ground (F.G.) terminal of the power supply is connected to an

actual ground.

In case noise generating equipment (switching regulator, inverter motor,

etc.) is used in the vicinity of this product, connect the frame ground

(F.G.) terminal of the equipment to an actual ground.

Do not use during the initial transient time (500ms approx.) after the

power supply is switched on.

Extension up to total 25m is possible, for both emitter and receiver, with

0.2mm2, or more, cable. However, in order to reduce noise, make the

wiring as short as possible.

Do not run the wires together with high-voltage lines or power lines or put

them in the same raceway. This can cause malfunction due to induction.

Take care that the sensor is not directly exposed to fluorescent light from

a rapid-starter lamp or a high frequency lighting device, as it may affect

the sensing performance.

Avoid dust, dirt, and steam.

Take care that the sensor does not come in direct contact with water, oil,

grease, or organic solvents, such as, thinner, etc.

Do not use in an environment containing inflammable or explosive gas.

Make sure to use an isolation transformer for the DC power supply. If an

auto-transformer (single winding transformer) is used, this product or the

power supply may get damaged.

In case a surge is generated in the used power supply, connect a surge

absorber to the supply and absorb the surge.

The emitter and the receiver must face each other with their cable ends on

the same side. If they are set upside down, the sensor will not work correctly.

Receiver

Non-voltage contact or

NPN open-collector transistor

Low

High

: 0 to 2V

: 5 to 30V, or open

or

Internal circuitUsers,circuitInternal circuit Users,circuit

Color code

(Brown) +V

(Blue) 0V

(Orange/Violet)

Synchronization wire

(Orange/Violet)

Synchronization wire

D D

Tr

ZD

EE

(Pink) Input

(Note 1)

(Brown) +V

Load

(Blue) 0V

Job

indicator

Job

indicator

(Black)

Output

(Brown) +V

(Blue) 0V

(Orange/Violet)

Synchronization wire

(Orange/Violet)

Synchronization wire

(Pink) Input

(Note 1)

(Brown) +V

(Blue) 0V

(Black)

Output

Color code

Color code Color code

Emitter

ReceiverEmitter

100mA max.

Notes: 1)

2)

3)

Symbols... :

Reverse supply polarity protection diode

: Surge absorption zener diode

: NPN output transistor

: Job indicator

Input (pink) is the job indicator input when No. 4 of the operation mode switch on the

emitter is set to the OFF side, and it is the test input when the switch is set to the ON side.

In order to use the job indicator as a large operation indicator, connect the input

(pink) of the emitter to the output (black) of the receiver.

When the test input is set, the job indicator does

not light up or blink.

Non-voltage contact or

PNP open-collector transistor

Low

High

: 0 to 2V, or open

: 8V to +V

or

Internal circuitUsers,circuitInternal circuit Users,circuit

D D

Tr

ZD

EE

Load

100mA max.

Sensor circuit

Sensor circuit

Job

indicator

Job

indicator

Sensor circuit

Sensor circuit

D

ZD

Tr

E

Notes: 1)

2)

3)

Symbols... :

Reverse supply polarity protection diode

: Surge absorption zener diode

: PNP output transistor

: Job indicator

Input (pink) is the job indicator input when No. 4 of the operation mode switch on the

emitter is set to the OFF side, and it is the test input when the switch is set to the ON side.

In order to use the job indicator as a large operation indicator, connect the input

(pink) of the emitter to the output (black) of the receiver.

When the test input is set, the job indicator does

not light up or blink.

D

ZD

Tr

E