䢇

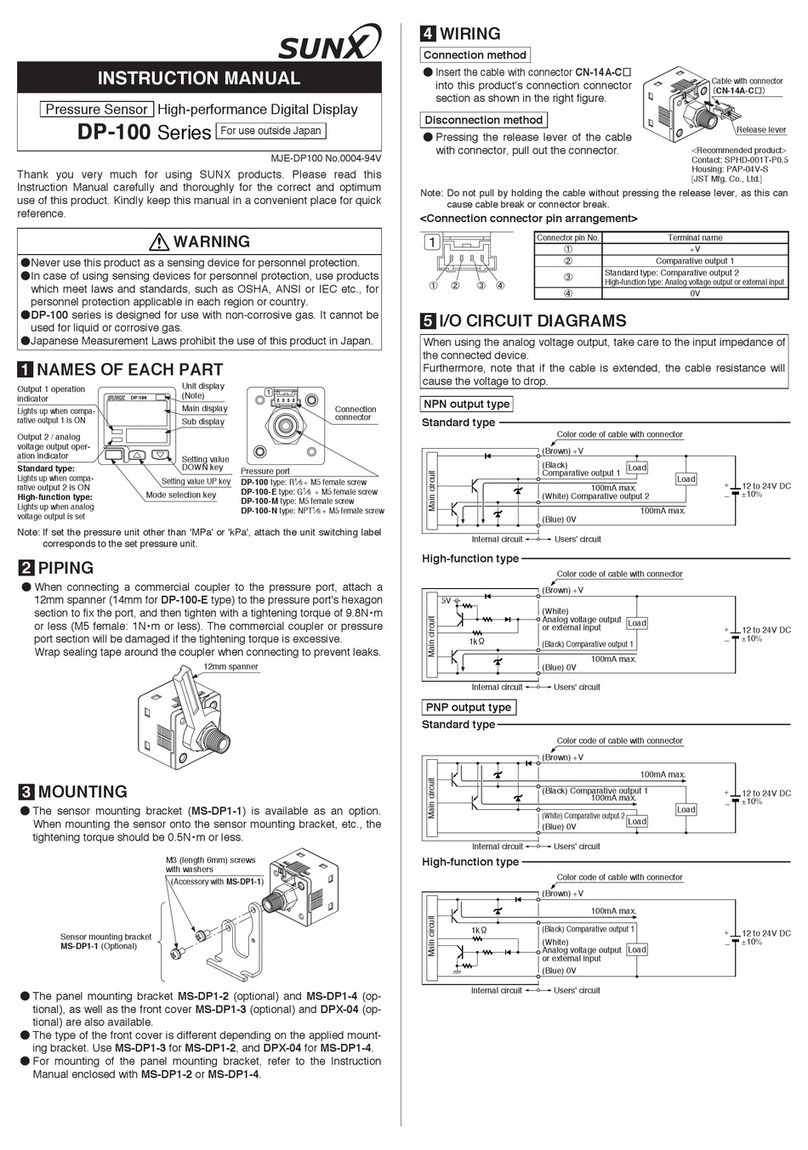

Make sure to carry out the wiring in the power supply off condition.

䢇 Verify that supply voltage variation is within the rating.

䢇 If power is supplied from a commercial switching regulator,

ensure that the frame ground (F.G.) terminal of the power supply

is connected to an actual ground.

䢇 In case noise generating equipment (switching regulator,

inverter motor, etc.) is used in the vicinity of this product,

connect the frame ground (F.G.) terminal of the equipment to an

actual ground.

䢇 Do not use during the initial transient time (50ms) after the

power supply is switched on.

䢇 Do not run the wires together with high-voltage lines or power lines

or put them in the same raceway. This can cause malfunction due

to induction.

䢇

Extension up to total 100m is possible with 0.3mm

2

, or more, cable.

However, take care that the output voltage drops when the cable

is extended.

䢇 Avoid dust, dirt, and steam.

䢇 Take care that the product does not come in direct contact with

water, oil, grease or organic solvents, such as, thinner, etc.

CAUTIONS

2

SPECIFICATIONS

1

INSTRUCTION MANUAL

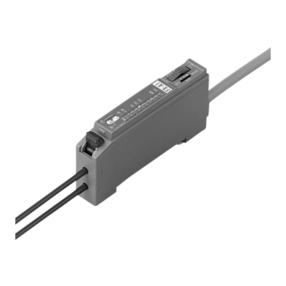

Slim body analog fiber sensor

FX-11A

12 to 24V DCⳲ10% Ripple P-P 10% or less

35mA or less

Analog voltage

• Output voltage: 1 to 5V

(proportional to incident light intensity)

• Output current: 5mA or less

• Output impedance: 47Ω

• Load resistance: 2kΩor more

• Temperature characteristics: 0.3% F.S. /⬚C or less

Switchable either 1ms or less, or 10ms or less

Incorporated

ⳮ

10 to

Ⳮ

55⬚C (No dew condensation or icing allowed)

Storage:

ⳮ

20 to

Ⳮ

70⬚C

35 to 85% RH, Storage: 35 to 85% RH

Red LED (modulated)

Enclosure: Heat-resistant ABS

Cover: Polycarbonate, Fiber lock lever: PES

0.2mm24-core cabtyre cable, 2m long

60g approx.

MS-DIN-2 (Amplifier mounting bracket): 1 No., Adjusting screwdriver: 1 No.

Designation

Item Model No.

Supply voltage

Current consumption

Analog output

Response time

Interference prevention function

Ambient

temperature

Ambient humidity

Emitting element

Material

Cable

Weight

Accessories

Slim Body Analog Fiber Sensor

FX-11A

Thank you very much for using SUNX sensors. Please read this

Instruction Manual carefully and thoroughly for the correct and

optimum use of this sensor. Kindly keep this instruction manual in a

convenient place for quick reference.

MOUNTING

3

Note: 1) In case the fiber cables are not inserted to a position where they stop, the

sensing range reduces.

2) With the coaxial reflective type fiber, such as, FD-G4 or FD-FM2, insert the

center fiber cable (single-core) into the beam-emitting inlet and the outer fiber

cable (multi-core) into the beam-receiving inlet. If they are inserted in reverse,

the sensing accuracy will deteriorate.

This product is not a safety sensor. Its use is not intended or

designed to protect life and prevent body injury or property

damage from dangerous parts of machinery. It is a normal

object detection sensor.

How to mount the amplifier

1 Fit the rear part of the amplifier on

the attached amplifier mounting

bracket (MS-DIN-2) or a 35mm

width DIN rail.

2 Press down the front part of the

amplifier on the amplifier mounting

bracket (MS-DIN-2) or the DIN rail

to fit it.

How to remove the amplifier

1

Push the amplifier forward.

2 Lift up the front part of the amplifier

to remove it.

How to connect the fiber cables

1 Unlock the fiber lock lever.

2

Insert the fiber cables slowly

into the inlets until they stop.

3 Lock the fiber lock lever in the

original position.

䢇Precautions for fiber

•Do not expose the fiber cable to any organic solvent.

•Do not apply excessive tensile force to the fiber cable.

•Wipe dirt or stains from the sensing faces with a soft cloth.

•The bending radius of the fiber cable must be R25mm or more. If the bending

radius is smaller, the sensing ability is decreased. However, as there are fibers

which can be bent at less than R25mm, their bending radius should be equal to, or

more, than the value specified in their catalog.

•The free-cut fiber cables must be cut with a fiber cutter before insertion into the

amplifier.

Note: Cut only one fiber cable at a time.

Once a fiber cable is cut off at a hole, do not use that hole again.

•The sleeve part bending radius of fiber with sleeve must be R10mm or more.

•Fiber attachments are enclosed

with the small diameter free-cut

fiber. Use the shorter attachment.

•Take care that the sensor is not directly exposed to fluorescent light from a rapid-

starter lamp or a high frequency lighting device, as it may affect the sensing

performance.

•The tightening torque must not exceed the values given below.