Important: Water lines MUST be thoroughly ushed BEFORE

and AFTER installing the faucet to prevent foreign matter i.e.

copper chips, sand, stones, etc. from clogging and possibly

damaging the sealing surfaces of the cartridge.

Note: Recommended minimum operating water supply

pressure is 40 psi.

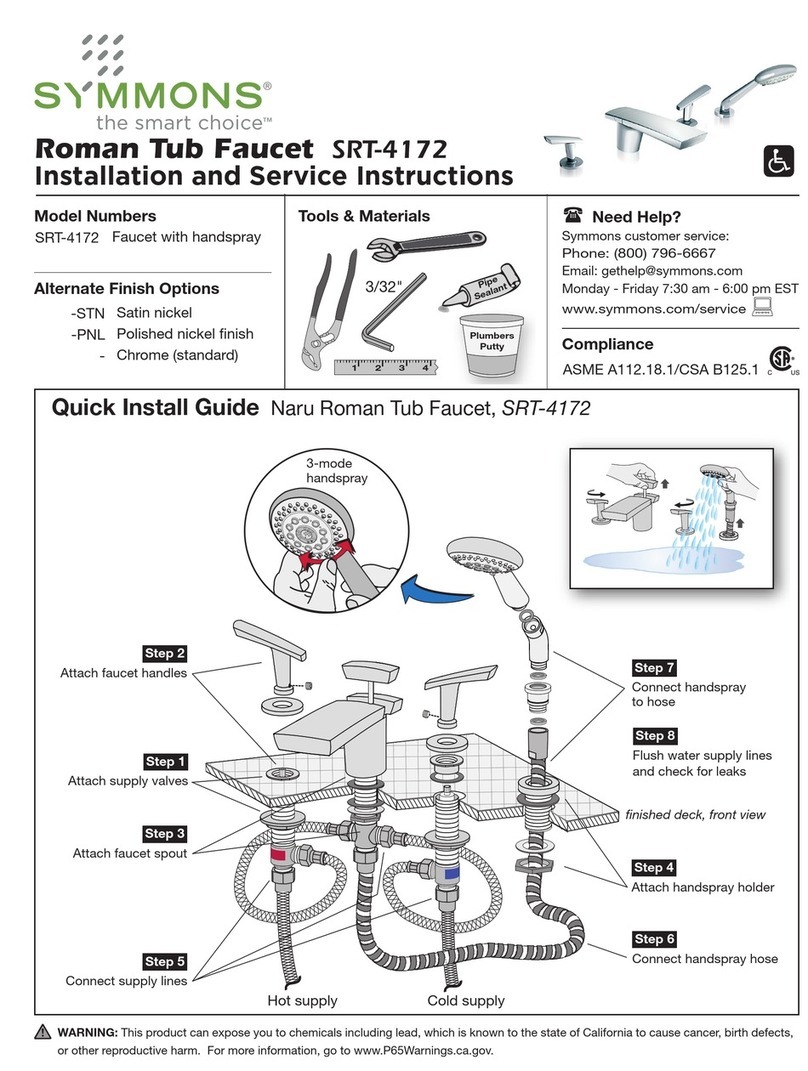

INSTALLATION

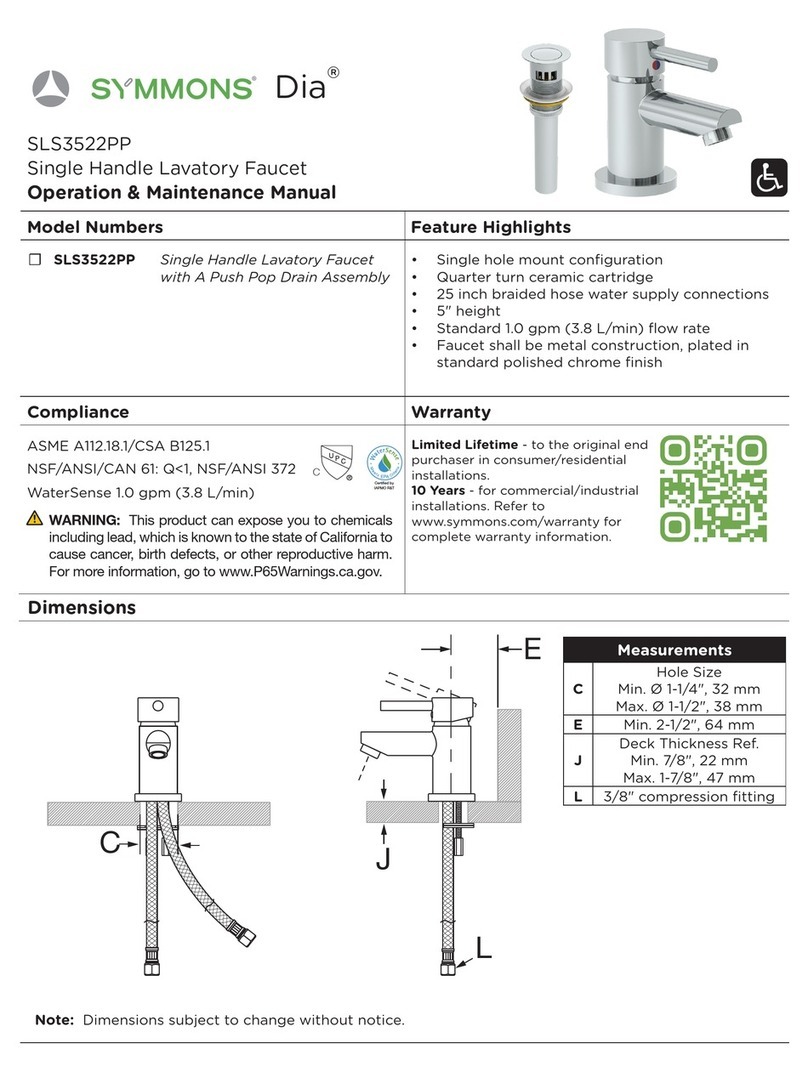

(Supply stop valves must have a 3/8” O.D. compression outlet.)

1. S-60 Series: Remove nut and ferrule from supply stops, install

in-line check/screen assembly (LL-71B) on male outlet of stops.

2. Install SPF-KIT loosely on faucet. Position faucet through sink or

counter with mounting gasket under base. Secure faucet tighten-

ing nuts from under side.

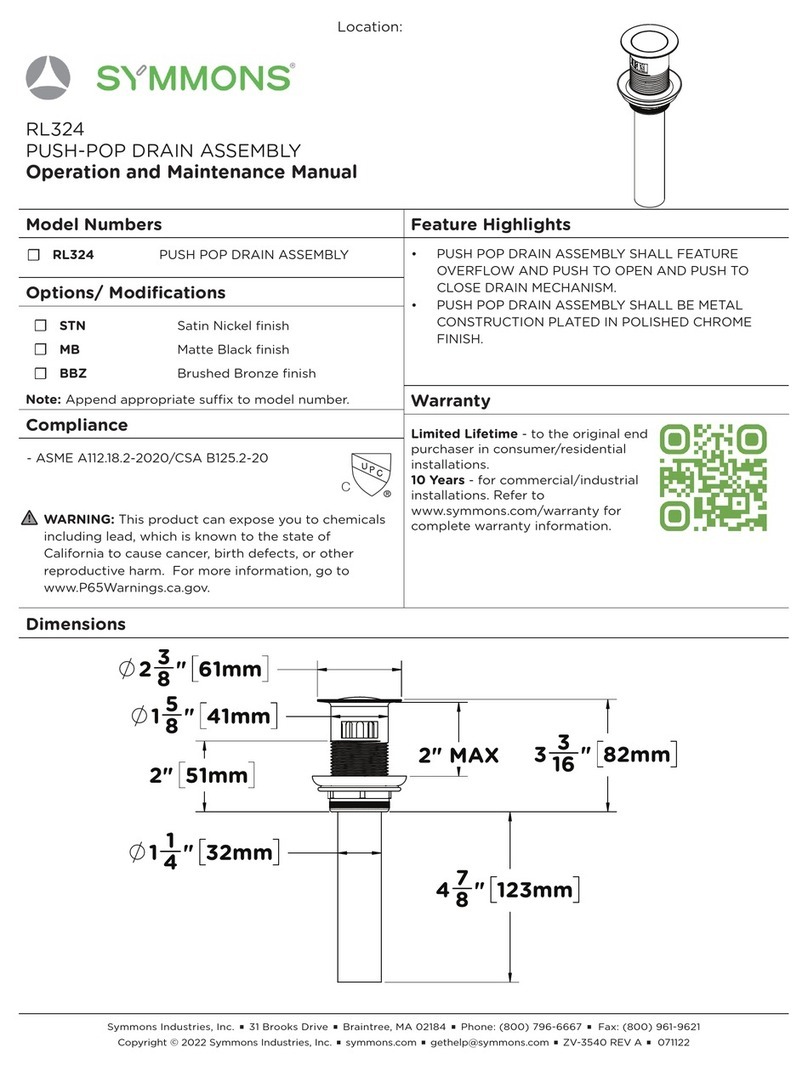

3. Installdrainassembly.Sealunderangewithputty.

4. S-60 Series: Carefully bend copper supplies to meet water

supplies using palms of hands to avoid kinking tubing or fractur-

ing solder joints. DO NOT REMOVE tape on copper supplies.

Connect hot supply to left tube and cold supply to right tube

using appropriate lengths of 3/8” O.D. tubing between faucet

supplies and in-line check/screen assembly.

S-61 Series: Connect cold or tempered supply to faucet supply

using appropriate length of 3/8” O.D. tubing between faucet and

in-line check/screen assembly.

5. S-60 Series:Toushfaucetremoveaerator(LN-100or

LN-101)andturnvalvehandletofullcoldposition.Opensupply

anddepresshandleholdingdownfor10seconds,rotatehandleto

hot position, open supply and repeat above procedure. Hold down

handleandrotatefromlefttorighttoushlinesthoroughly.

Allow faucet to shut off and replace aerator.

S-61 Series:Toushfaucetremoveaerator(LN-100or

LN-101)andopensupplystopdepresshandleandholddownfor

10seconds.Repeatseveraltimesandallowfaucettoshutoff.

Replace aerator.

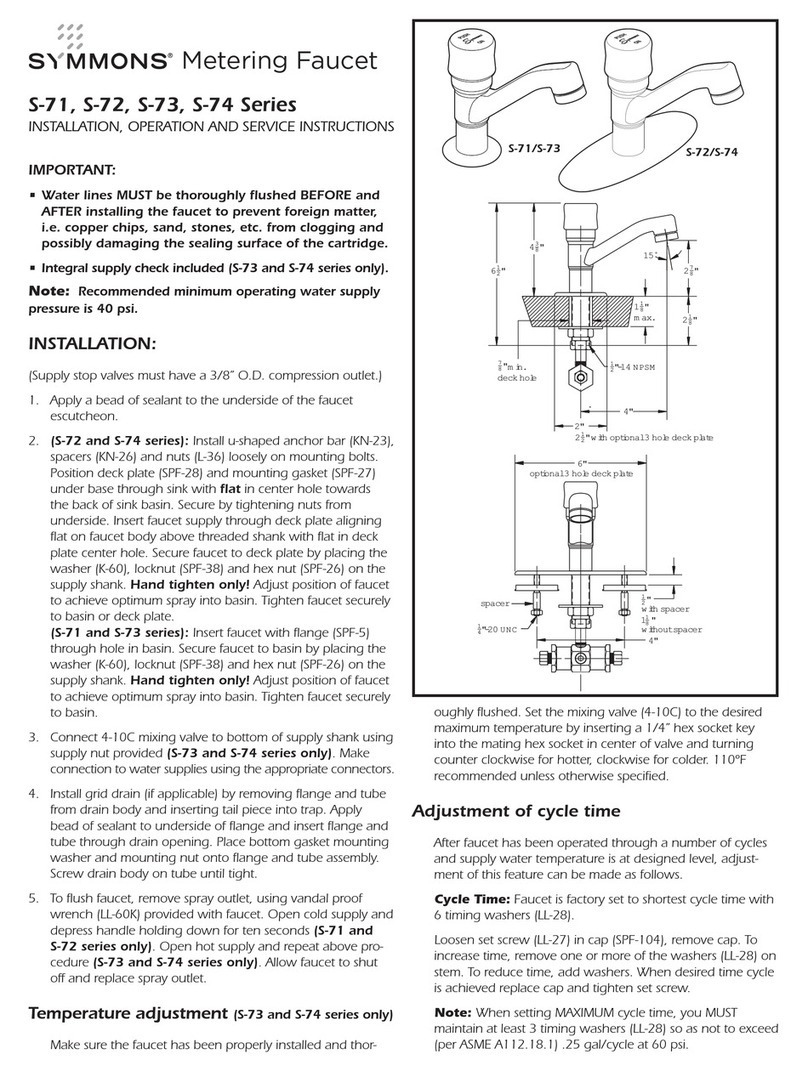

Adjustment of cycle time and temperature

After faucet has been operated through a number of cycles and

supply water temperature is at designed levels, adjustments to

these features can be made as follows.

Cycle Time: Faucet is factory set to shortest cycle time

with 7 timing washers (LL-28). To increase time, loosen

allen screw (LL-27) with a 3/32” hex socket key, remove

handle(LT-100orRL-156)andremoveoneormoreof

the washers (LL-28) on stem. To reduce time, add washers.

Note: When setting MAXIMUM cycle time, you MUST

maintain at least 5 timing washers (LL-28) so as not to exceed

(perASMEA112.18.1).25gal/cycleat60psi.

Temperature limit adjustment (S-60 Series only):

Loosen allen screw (LL-27) with a 3/32” hex socket key.

Removehandle(RL-156),loosennut(LL-6)andturnstem(LL-

1A)todesiredmaximumtemperature(110°Frecommended).

Turnlimitstopwasher(LL-23N)clockwiseuntilapositivestop

isreachedagainstbackoffaucet.Tightennut(LL-6),replaceand

tightenhandle(RL-156).Faucetwilloperatefromthefullcold

position to the maximum hot temperature that has been set.

Reverse operation (S-60 Series only)

For piping simplicity in back to back installation or when hot

supply is on right, the faucets internal operation can be quickly

reversed.

Removehandle(RL-156),nut(LL-6),andlimitstopwashers

(LL-22N)&(LL-23N),turnstem180°sothatredmarkingis

facing toward front.

Replace limit stop washers, adjust to desired temperature (see

adjustment procedure in preceding paragraph), reassemble faucet

reversing above procedure.

Faucet will operate from the full cold position to the maximum

hot temperature that has been set.

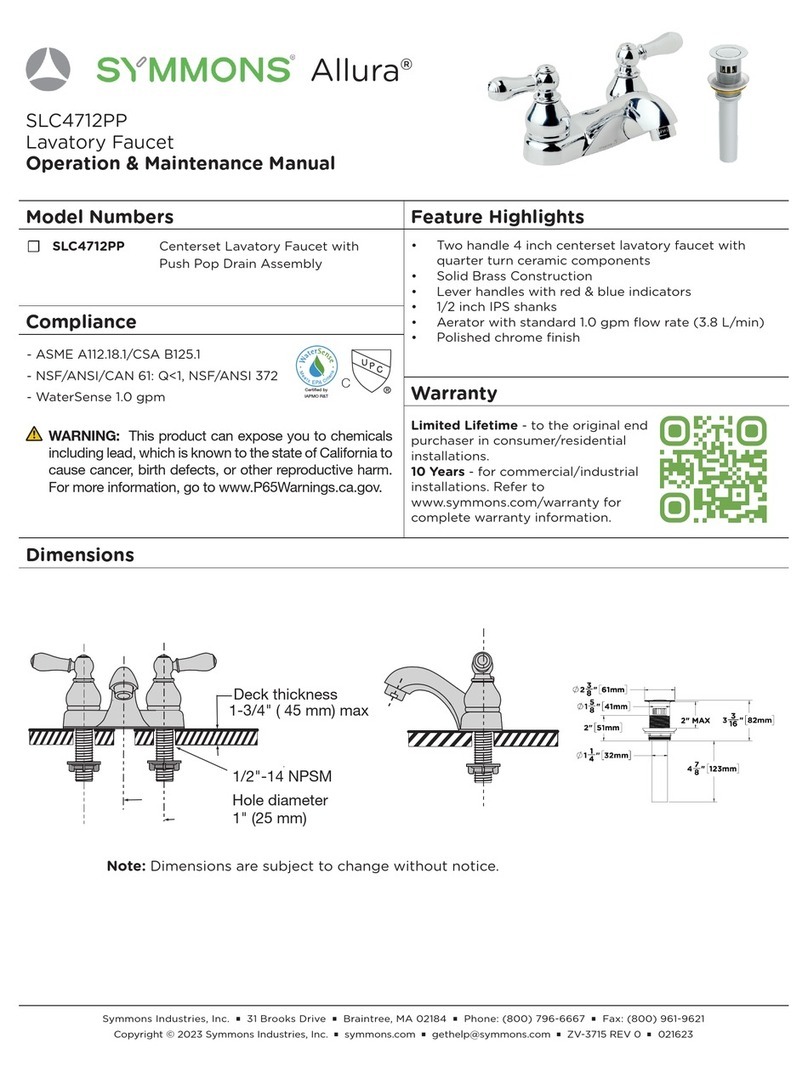

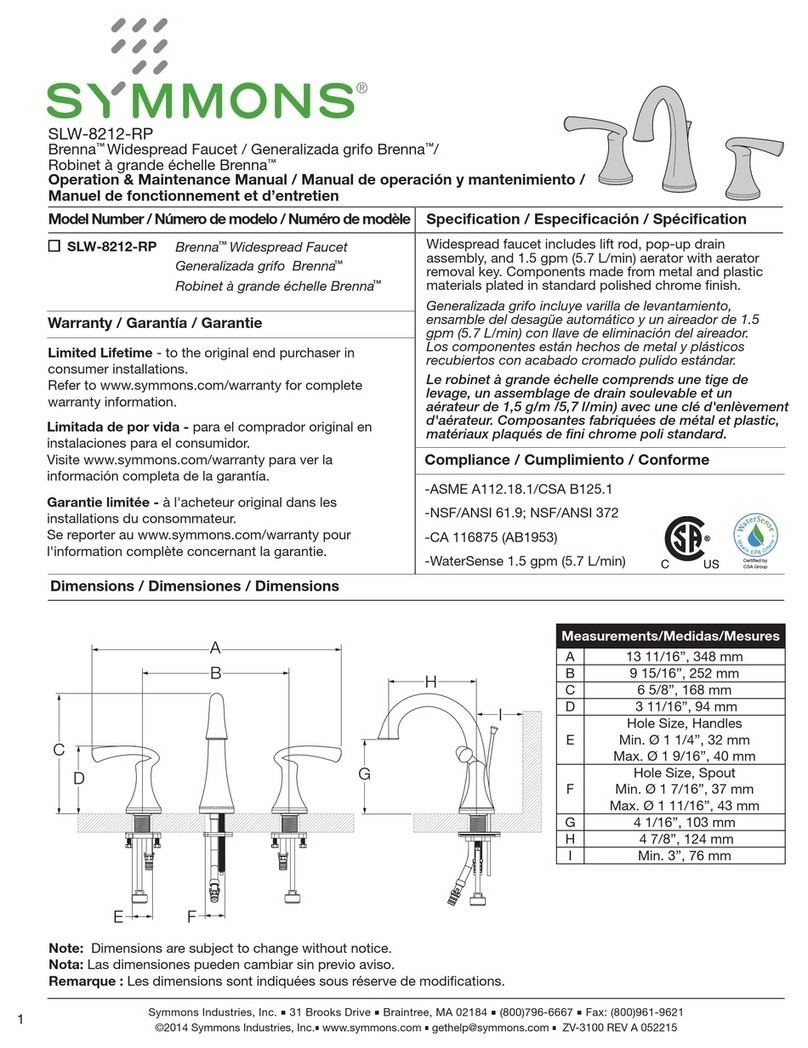

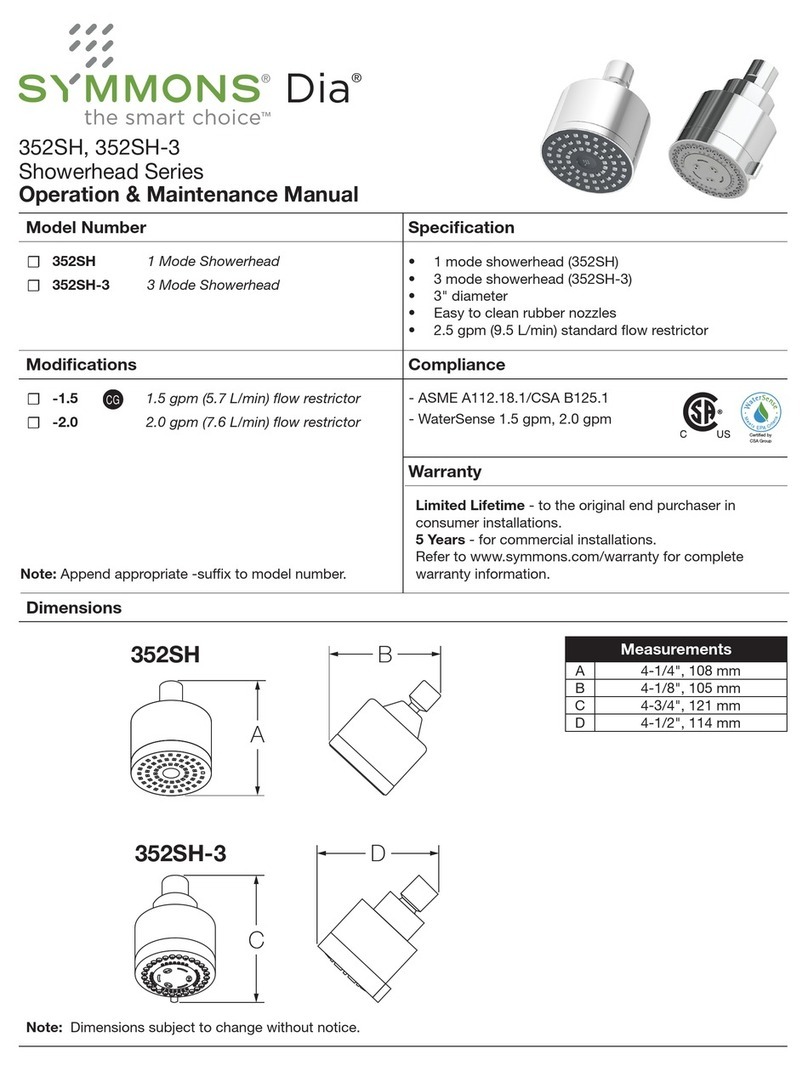

152mm

39

16''

90mm

2"

51mm

23

16''

56mm

32

112mm

41

16''

103mm

coldhot

117

32''

39mm

13

8''

23

8''

35mm

11

4''

32mm

61

2''

165mm

11"

279mm

3

8O.D.

copper

tubes

''

2"

51mm

2"

51mm

60mm

tape

in-line

check/

screen

assembly

9

16 -24 thread

3

8compression

''

61

2''

165mm

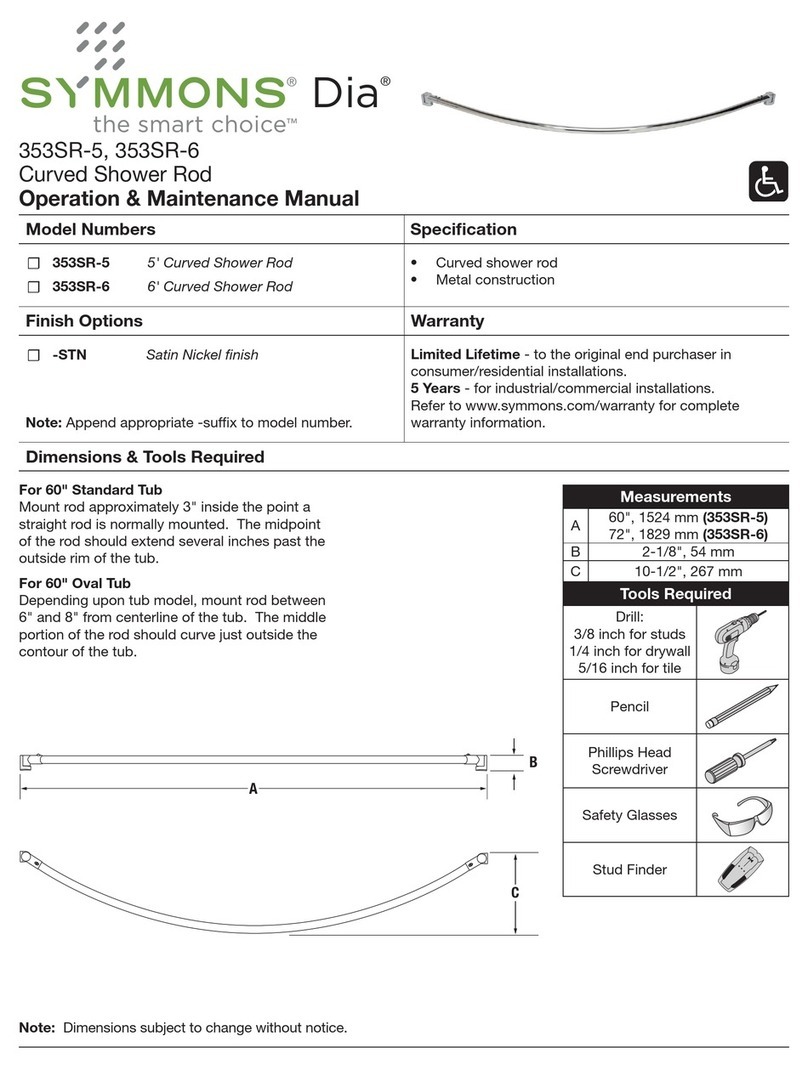

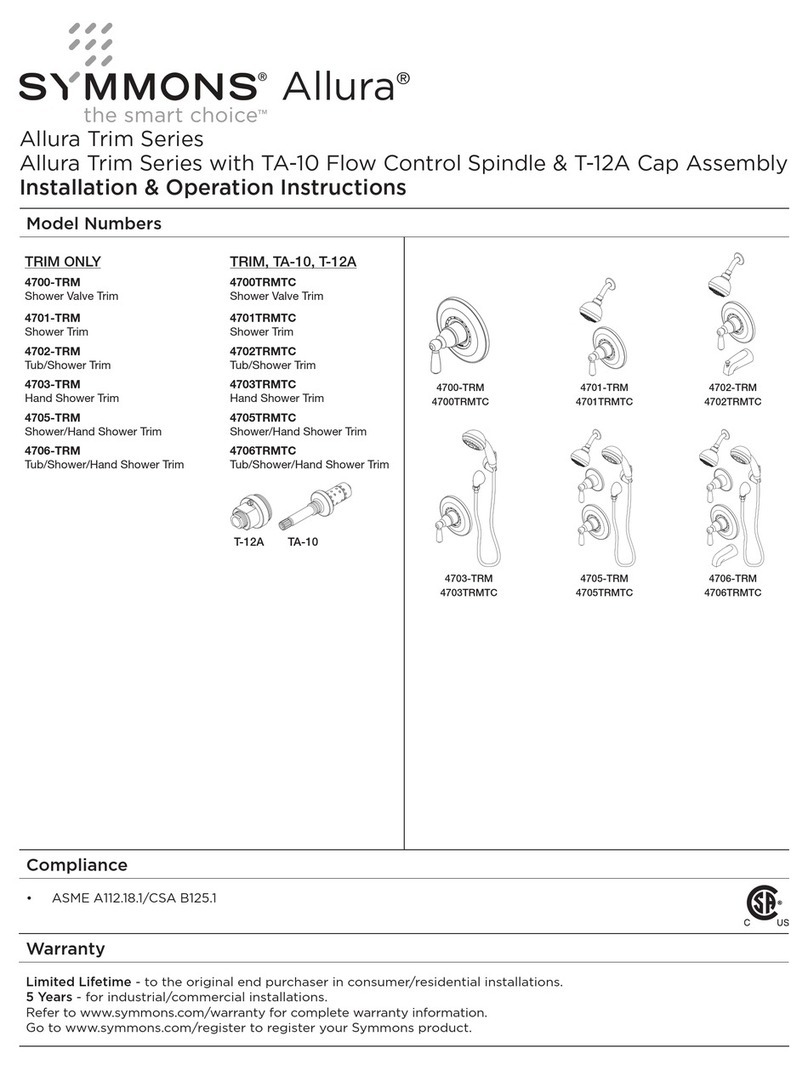

152mm

39

16''

90mm

2"

51mm

23

16''

56mm

32

112mm

41

16''

103mm

117

32''

39mm

13

8''

35mm

11

4''

32mm

11"

279mm

3

8O.D.

copper

tube

''

2"

51mm

2"

51mm

23

8''

60mm

in-line

check/

screen

assembly

9

16 -24 thread

3

8compression

''

S-60 Series

S-61 Series

SCOT S-60 Series

Slow-Closing Temperature Lavatory Faucet

Installation & Service Instructions

Metering Faucet S-61 Series

Metering Lavatory Faucet