4TB8100 Installation and Operation Manual

© Tait Electronics Limited June 2005

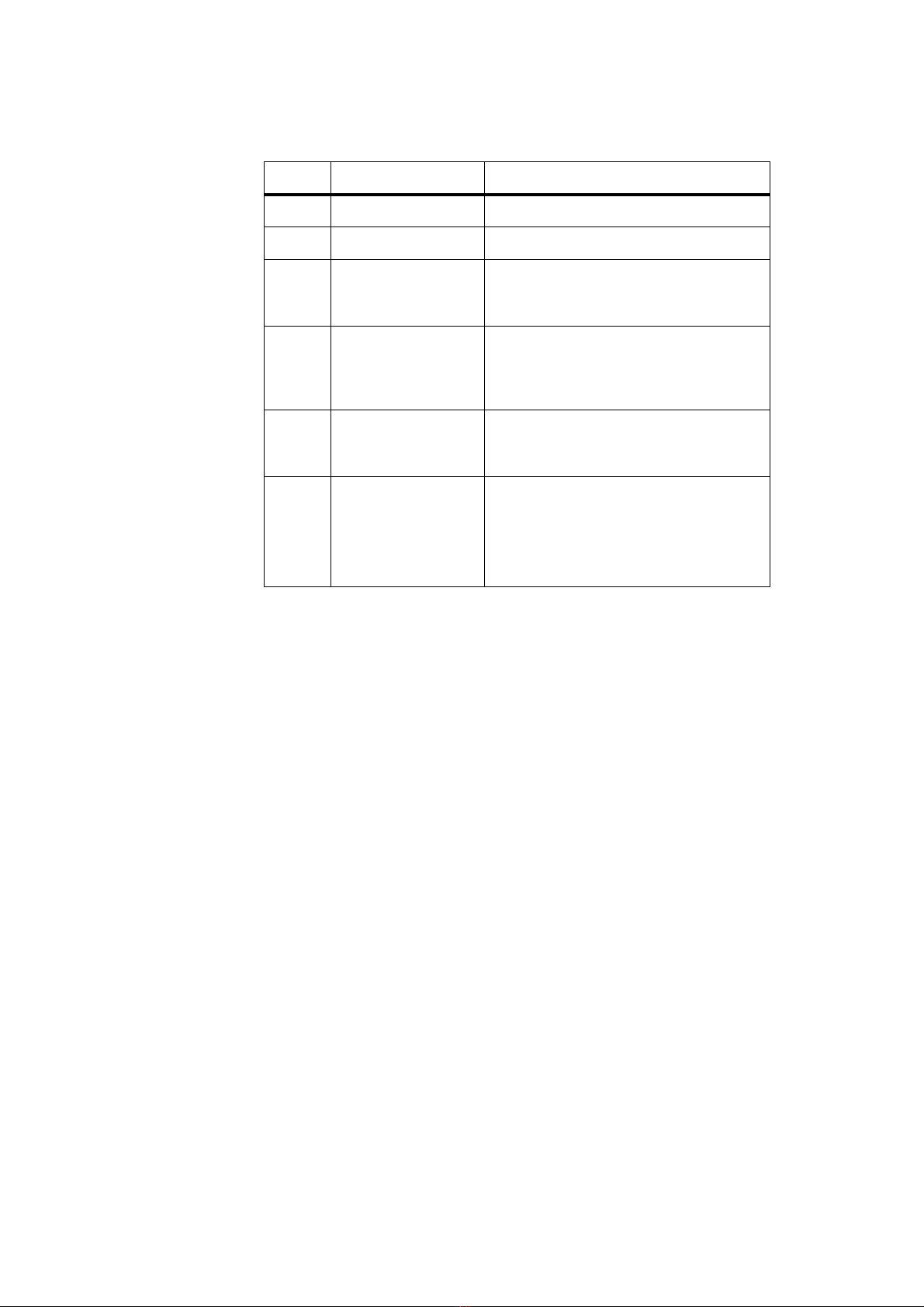

4.7 Fan Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

4.8 Power Saving. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

4.8.1 Power Saving Measures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

4.8.2 Power Saving Modes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

4.8.3 Overview of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

4.8.4 Using the Service Kit with Power Save Base Stations . . . . . . . . . . . . . 63

4.8.5 Configuring Receiver Gating for Base Stations with Power Save. . . . . 65

5 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

5.1 Personal Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

5.1.1 Lethal Voltages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

5.1.2 Explosive Environments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

5.1.3 Proximity to RF Transmissions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

5.1.4 High Temperatures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

5.2 Equipment Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

5.2.1 ESD Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

5.2.2 Antenna Load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

5.2.3 Equipment Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

5.2.4 Installation and Servicing Personnel . . . . . . . . . . . . . . . . . . . . . . . . . . 75

5.3 Regulatory Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

5.3.1 Distress Frequencies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

5.3.2 FCC Compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

5.3.3 Unauthorised Modifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

5.3.4 Health, Safety and Electromagnetic Compatibility in Europe. . . . . . . . 76

5.4 Environmental Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

5.4.1 Operating Temperature Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

5.4.2 Humidity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

5.4.3 Dust and Dirt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

5.5 Grounding and Lightning Protection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

5.5.1 Electrical Ground . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

5.5.2 Lightning Ground. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

5.6 Recommended Tools. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

5.7 Ventilation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

5.7.1 Ambient Air Temperature Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

5.7.2 Cabinet and Rack Ventilation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

5.8 Installing the Base Station System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

5.8.1 Unpacking the Equipment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

5.8.2 Mounting the Subrack. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

5.8.3 Auxiliary Support Bracket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

5.8.4 Optional Slide Mounting Rails . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

5.8.5 Cabling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

6 Replacing Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

6.1 Saving the Base Station’s Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

6.2 Preliminary Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

6.3 Replacing the Control Panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89