OPERATION5

SETTING6

2/4

・Left-sidesetting:Standardoperationmode(defaultsetting)

・Right-sidesetting:Automaticsensitivityadjustmentmode

●

Preparation

Firmlysecurethewiringconnectorsasdescribedinsection4

"Connections".BeforeturningthepowerON,removetheswitch

coverandmaketheappropriateswitchselections(seesection6(1)

"Switches").

*Afterchangingtheswitchsettings,besuretoturnthepower

OFFandbackON.

(1)TurnthepowerON.

*BeforeturningthepowerON,checkagaintoverifythatthe

connectionsarecorrect.

Usecarebecausetheoutputsarenotequippedwithshort-circuit

protectioncircuits.

(2)TheTEACHmodeisestablishedwhenthepoweristurnedON.

*WhenintheTEACHmode,verifythatnothingisblockingthelight

beam.

(3)Performstandardoperation(seesection6(2)"Functions").

*Becausetheproducthasbeenadjustedtodetectwaferswhich

arenearlytransparent,anfalseoutputcouldoccuriftheproduct

issubjectedtoanimpactshockorvibrationwhilethesensoris

movingorstationary.

Moreover,amalfunctioncouldoccurifthecomb'stipistouched

bythewafer,orbyafinger.

Ifthecombistouchedinthismanner,theTEACHoperationmust

berepeated(seesection6(2)"Functions").

*Ifthecombbecomesdamaged,replaceitasdescribedinsection

8"MaintenanceandInspection".

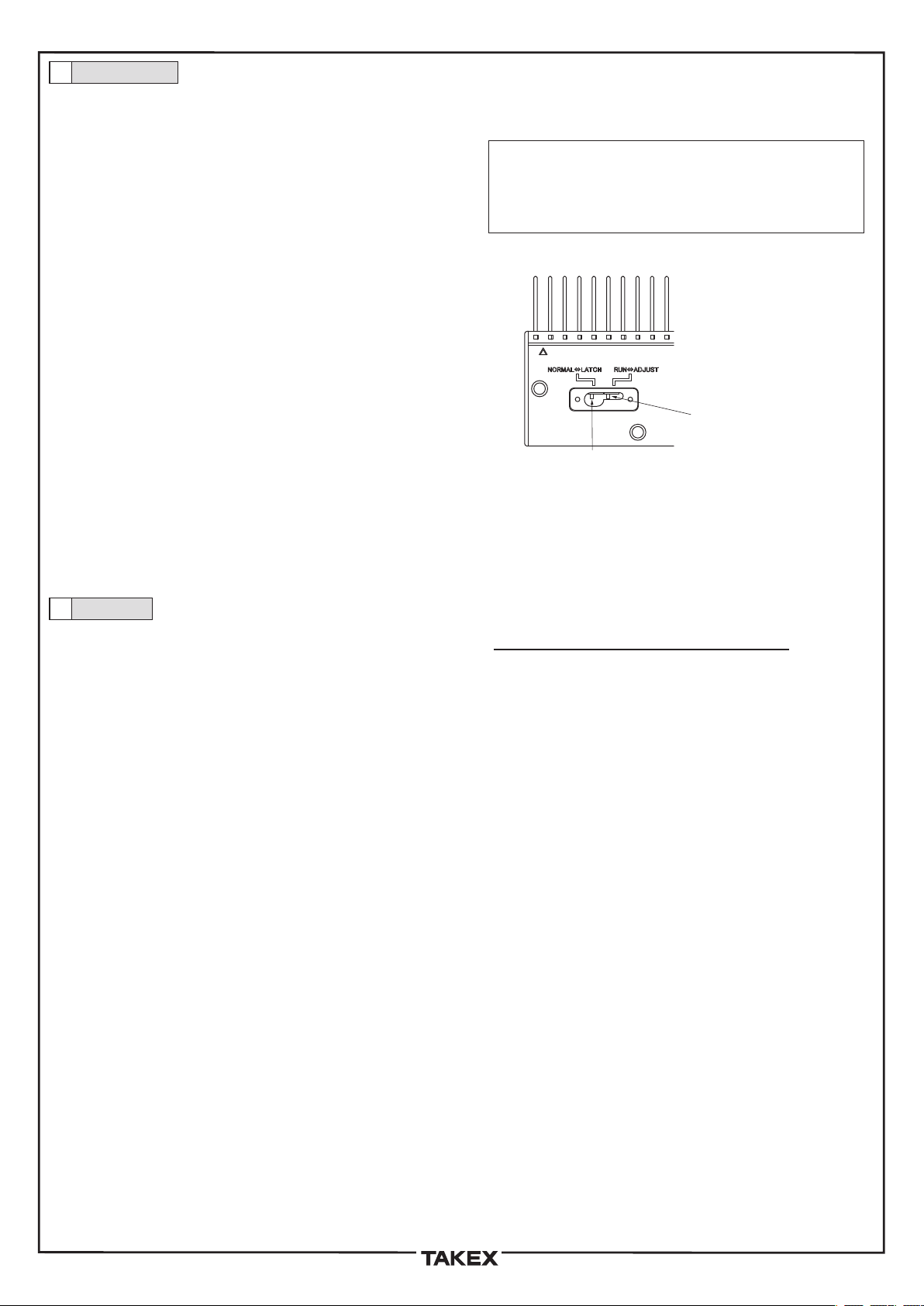

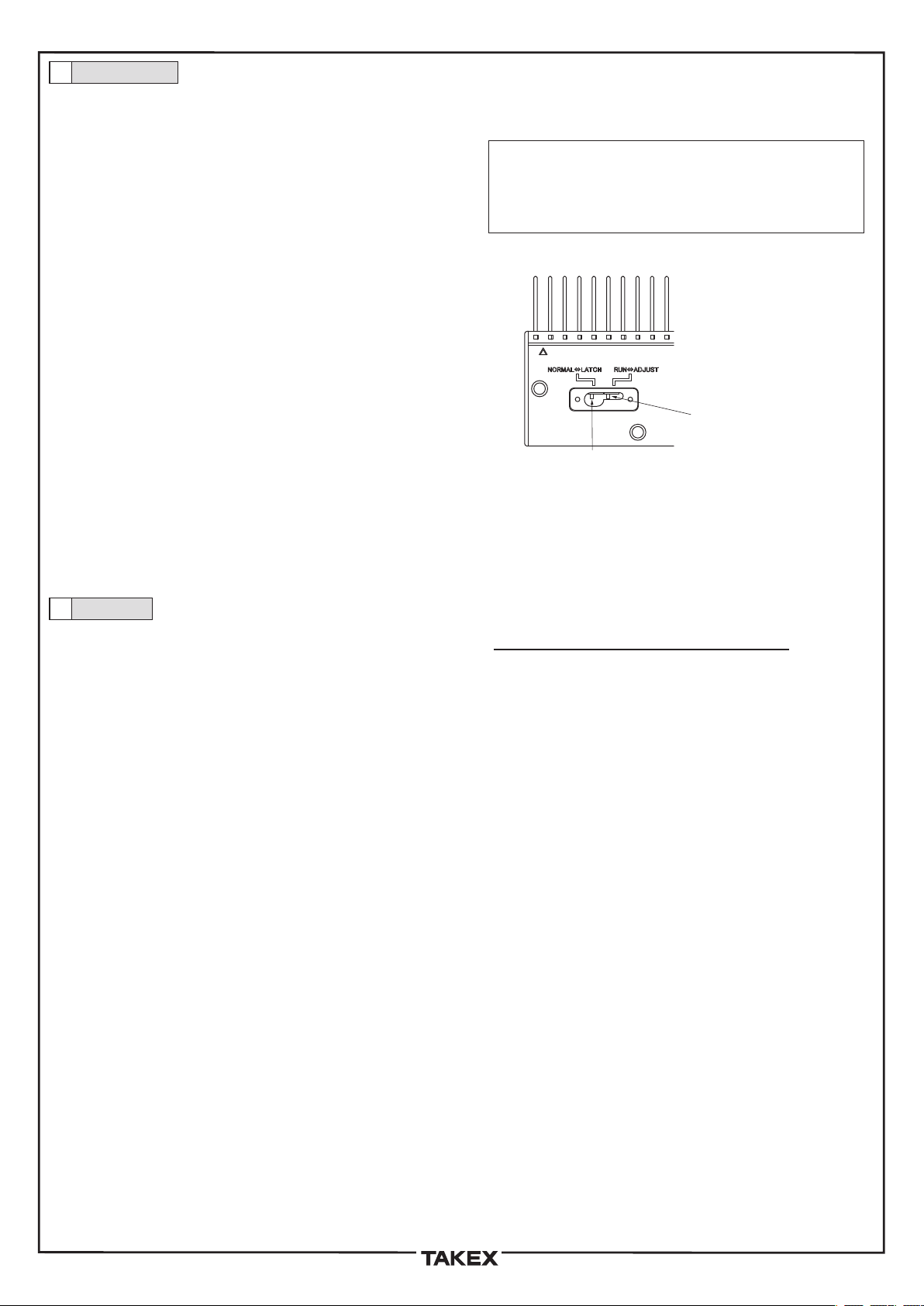

(1)Switches(seeFig.1)

Openthesensor'sswitchcover,thenspecifythedesiredoperation

modebysettingthetwoswitches.

●

SwitchA(outputoperationsetting)specifiesthesensor

outputoperation.

・Normaloutputmode:settheswitchtotheleft.

(OutputON/OFFoccursaccordingtoobjectpresence/absence.

Thisisthedefaultsetting.)

・Latchoutputmode:settheswitchtotheright

(OncetheoutputswitchesON,thisONstatusismaintained.)

*Thelatchoutputmode(sensoroutputONHOLD)canbe

canceledbyexecutingtheLightemissioninhibitsignal.

●

SwitchB(automaticsensitivityadjustmentsetting)is

usedforsensorsensitivityadjustments.

Thisadjustmentoperationautomaticallyadjuststhesensitivityof

eachopticalaxischannelindividuallyandisrequiredonlyaftera

combhasbeenreplaced.

Besuretoperformtheadjustmentafterreplacingacombwhichhas

becomedamaged,etc.

SettheswitchBtoautomaticsensitivityadjustmentmodeandturn

thepowerON.

Besurethatnothingisblockingthelightduringtheautomatic

sensitivityadjustmentoperation(lightreceptionisrequiredatthis

time).

Followingtheautomaticsensitivityadjustmentoperation,besureto

returntheswitchsettingtothestandardoperationsuretoreturn

theswitchsettingtothestandardoperation

SwitchA:Outputoperationsetting

Normaloutputmode←→Latchoutputmode

SwitchB:Automaticsensitivityadjustmentsetting

Standardoperationmode←→Automaticsensitivityadjustment

(2)Functions

●

PowerONandTEACHoperation

WhenpoweristurnedONinthestandardoperationmode,the

internalcircuit'soperationischecked,andaninitialTEACH

operationoccurs.

BesurethatnothingisblockingthelightatpowerON.

Ifteachingcannotbeperformedforsomereason(lightisblocked,

combismissingordamaged,etc.),theerroroutputturnsON,and

theerrorchannel'soutputturnsON/OFFrepeatedly.

●

Outputinhibitinput

Turnseachchannel'sopencollectoroutputOFFregardlessofthe

sensoroperationstatus.

Thisfunctioncanbeusedwhentheoutputsofmultiplesensors

areconnectedinparalleltoaPLC.

Thisfunctioninhibitstheoutputsofunnecessarysensorswhichis

areconnectedtothePLC.

●

Lightemissioninhibitinput

WhenthisinputisturnedON,a"lightblocked"and"outputON"

statusoccursatallchannels.

WhenthisinputisturnedOFF,are-teachingoperationoccurs.

Performthisre-teachingoperationwhilethesensorremains

stationary.

Donotperformare-teachingoperationwhilethesensorisinmotion.

There-teachingoperationiscompletedwithinapproximately1sec

afterthelightemissioninhibitinputisturnedOFF.

After1secelapses,performamotionoperation.

Toobtainoptimaldetection,turnthelightemissioninhibitinputON

→OFFwhilethesensorisinastandbystatus(beforeproceeding

tothewaferdetectionoperation)inordertoperformre-teaching.

●

Erroroutput

AnerroroutputisissuedatpowerONifanoperationalproblem

exists(abnormalchannelcondition,insufficientlightreception,

lightabnormalityduetoadamagedcomb,malfunctiondueto

ambientlightinterference,etc.).

WhentheerroroutputturnsON,theerrorchannel'soutputturns

ON/OFFrepeatedly.

SwitchA:Outputoperation,setting(factorysetting)

SwitchB:Automatic

sensitivityadjustmentsetting