9SPECIFICATIONS 10 EXTERNAL DIMENSIONS

Unit: inch (mm)

■Option:Ceiling/Wallmountingattachment:BCW-401

Limited Warranty :

TAKEX products are warranted to be free from defects in material and workmanship for 12 months from original date of shipment. Our warranty does not cover

damage or failure caused by natural disasters, abuse, misuse, abnormal usage, faulty installation, improper maintenance or any repairs other than those provided

by TAKEX. All implied warranties with respect to TAKEX, including implied warranties for merchantability and implied warranties for tness, are limited in

duration to 12 months from original date of shipment. During the Warranty Period, TAKEX will repair or replace, at its sole option, free of charge, any defective

parts returned prepaid. Please provide the model number of the products, original date of shipment and nature of difculty being experienced. There will be

charges rendered for product repairs made after our Warranty Period has expired.

In Japan

Takex America Inc.

4/15 Howleys Road, Notting Hill,

VIC, 3168

Tel : +61 (03) 9544-2477

Fax : +61 (03) 9543-2342

Takenaka Engineering Co., Ltd.

83-1, Gojo-sotokan,

Higashino, Yamashina-ku,

Kyoto 607-8156, Japan

Tel : 81-75-501-6651

Fax : 81-75-593-3816

http : // www. takex-eng. co. jp /

Takex America Inc.

3350, Montgomery Drive,

Santa Clara,

CA 95054, U.S.A

Tel : 408-747-0100

Fax : 408-734-1100

http : // www. takex. com

Takex Europe Ltd.

Takex House, Aviary Court, Wade Road,

Basingstoke, Hampshire. RG24 8PE, U.K.

Tel : (+44)01256-475555

Fax : (+44)01256-466268

http : // www. takexeurope. com

In the U.S. In the U.K.

In Australia

COVERLOCKINGSCREW

WIRINGHOLE 1.44”(36.5)

3.74”(95)

3”(76)

3.29”(83.5)

3.54”(90)

5”(127)

2.43”(62.5)

φ0.16(φ4) HOLE

TROUBLESHOOTING

8

Completely inactive

Trouble Check Corrective Action

Sometimes inactive

Activated when

no person has passed

Alarm LED lights,

but connected devices

are inactives

(1) Connect wiring correctly, or repair problem wire.

(2) Check connected devises.

Alarm LED continues lighting

and alarm output doesn’t stop.

(Abnormal detection)

(1) Unstable power supply voltage. (1) Supply appropriate power voltage.

(1) Improper detection area settings (including detection distance).

(2) Improper function mode setting.

(3) Detection lens is covered with dust or water droplets.

(1) Readjust detection area.

(2) Readjust mode setting.

(3) Clean the lens with soft and dry cloth.

(1) Unstable power supply voltage.

(2) Something is moving within the detection area, or there are sudden

changes in temperature.

(3) A source of electrical noise (broadcasting station, amateur radio station,

etc.) is nearby.

(4) Strong light (direct or reflected) such as sunlight or headlights from

front side of the detection area.

(5) Detecting someone passing outside the detection area.

(6) There are many charges in temperature in detection area.

(7) Movement of pets is detected.

(8) Movement of robot cleaners is detected.

(1) Supply appropriate power voltage.

(2) Remove problem object.

(3) Change mounting location.

(4) Change mounting location or shield light with blinds, etc.

(5) Readjust detection area.

(6) Set signal count to "4".

(7) Prevent pets from entering detection area.

(8) Prevent robot cleaners from entering detection area.

(1) Power supply is not connected (including broken wiring).

(2) Power supply voltage is low.

(3) 1 minute has not passed yet since turning the power ON.

(4) The detection area is blocked by obstacles (which may include glass).

(5) Improper detection (including detection distance).

(6) Improper function mode setting.

(1) Check the power wiring.

(2) Supply appropriate power voltage.

(3) Wait approximately 1 minute.

(4) Remove obstacles.

(5) Readjust detection area.

(6) Readjust mode setting.

MAINTENANCE

Analyze possible problems according to the following table. If normal operations cannot be restored by

these means, contact either the dealer from whom you bought the unit or TAKEX.

●

●

To clean the device, use a soft, wet cloth and then wipe off any water drops. If the device is particularly dirty, dip the soft cloth in the water that contains a weak

neutral detergent. Wipe the device gently with the cloth, then wipe off any detergent that remains. Do not use substances such as thinner or benzene.

(The plastic parts may deform, discolor or change their properties.)

Perform operation checks on a regular basis.

(1) Wiring failure, broken wire, or short-circuit.

(2) Connected devices don’t function normally.

※Specifications and design are subject to change withoutpriornotice.

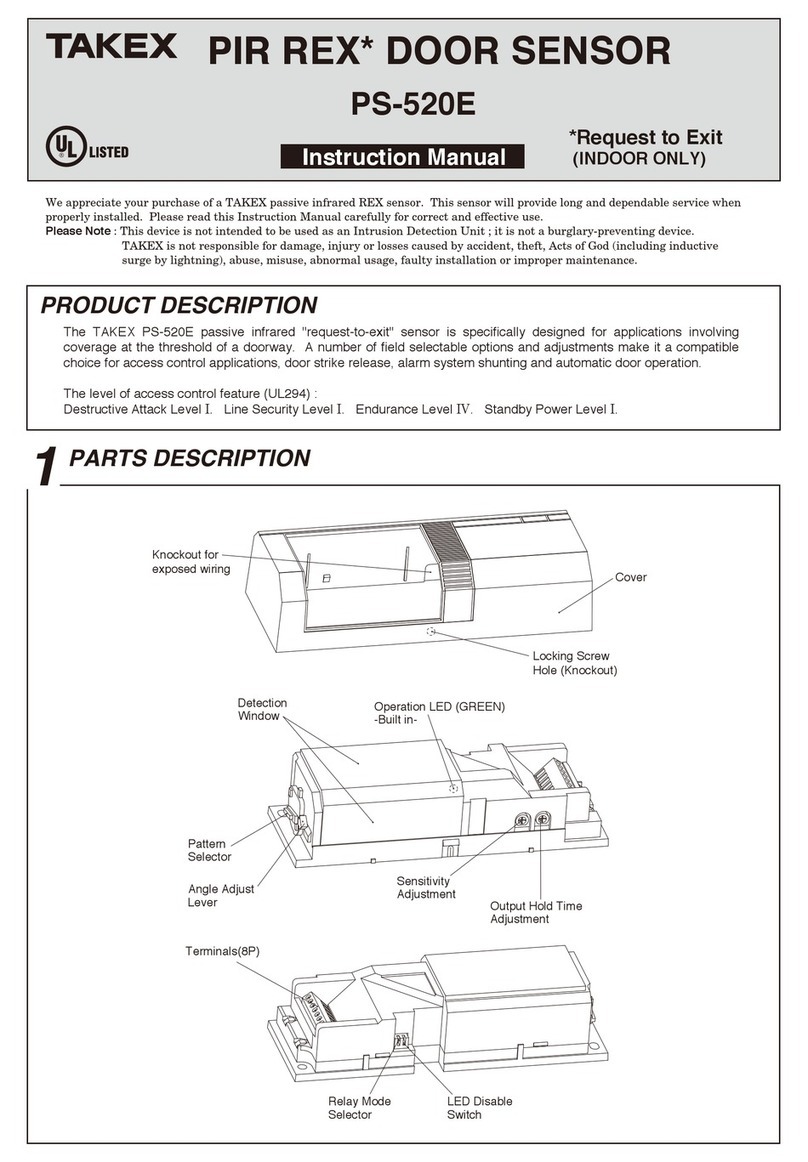

Model

Detection System

Coverage

Sensitive zone

Area adjustment

Supply Voltage

Current consumption

Alarm output

Tamper output

LED(Red)

Trouble signal

Ambient

temperature range

Mounting position

Wiring connections

Weight

Appearance

PA-480S

Passive infrared (Twin element・Pulse count)

Super Wide angle radius 26.3ʼ(8m)

64 (32pairs)

Downward 5 positions

9.5 to 28V DC(non-polarity)

20mA Max.

Dry contact N.C. (Semi-conductor)

Reset : Apporox, 2 sec.

30V DC (24V AC) 0.25A Max. (protective resistor 3.3Ω)

Dry contact N.C.

Open when cover is detached

30V DC 0.1A MAX. (protective resistor 3.3Ω)

Alarm LED Flickering (every 0.5 sec.) : Warming-up

Lighting (approx. 2 sec.) : Alarm

Flickering (every 2 sec.) : Trouble indication

Continuous lighting : Trouble alarm

Unit trouble : Monitorring inner circuit and wiring damage

・Operation : Trouble alarm

Low voltage trouble : Monitoring low voltage

・Operation : Trouble alarm

+14°F to +122°F (without dewdrops)

(−10℃to +50℃)

Indoor (Wall/pillar)

Ceiling mount is possible with optional attachment

Terminals

5.82oz (165g)

resin (White)

2021.8.26