⑦

Vielen Dank, dass Sie sich für unsere ”intelligente”

Vierstrahl-Aktiv-Infrarotschranke entschieden haben.

Die Schranke zeichnet sich bei ordnungsgemäßer

Montage durch eine lange Lebensdauer und hohe

Zuverlässigkeit aus.

Damit Sie die Aktiv-Infrarotschranke richtig einsetzen

und optimal nutzen können, bitten wir Sie, diese

Anleitung sorgfältig durchzulesen.

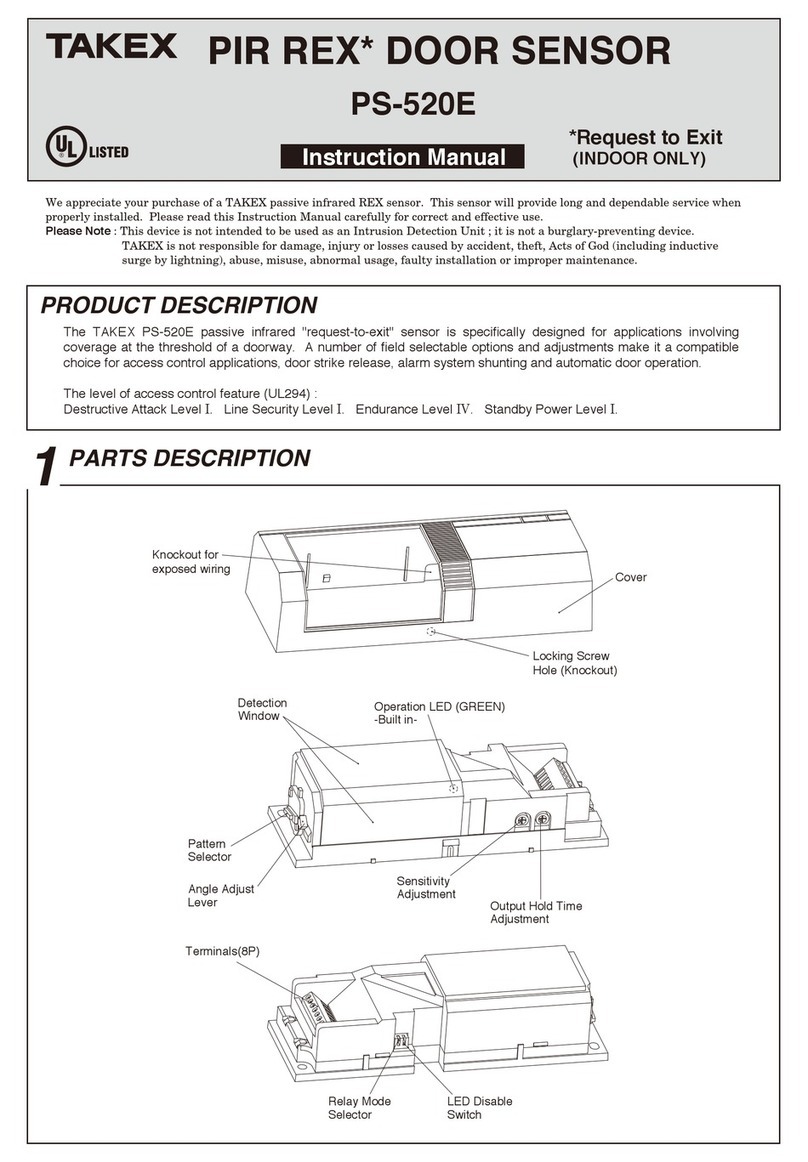

Produktbeschreibung

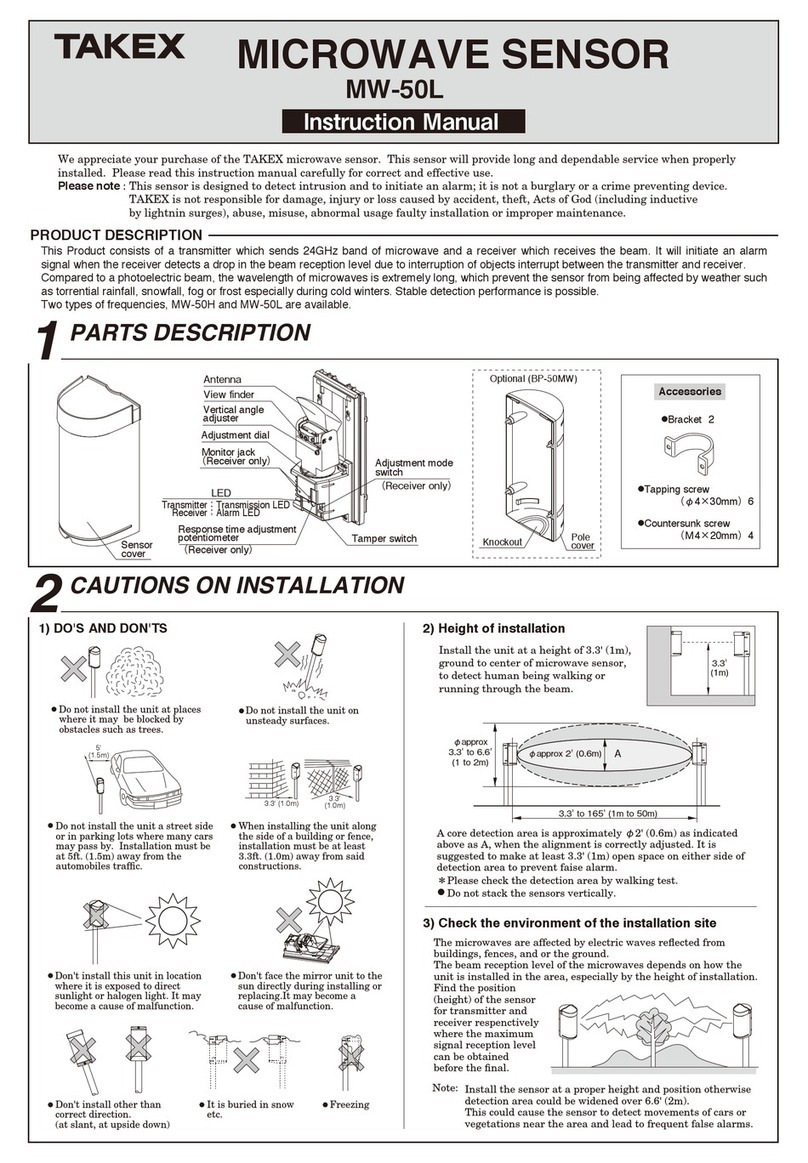

Bezeichnung der Teile

1

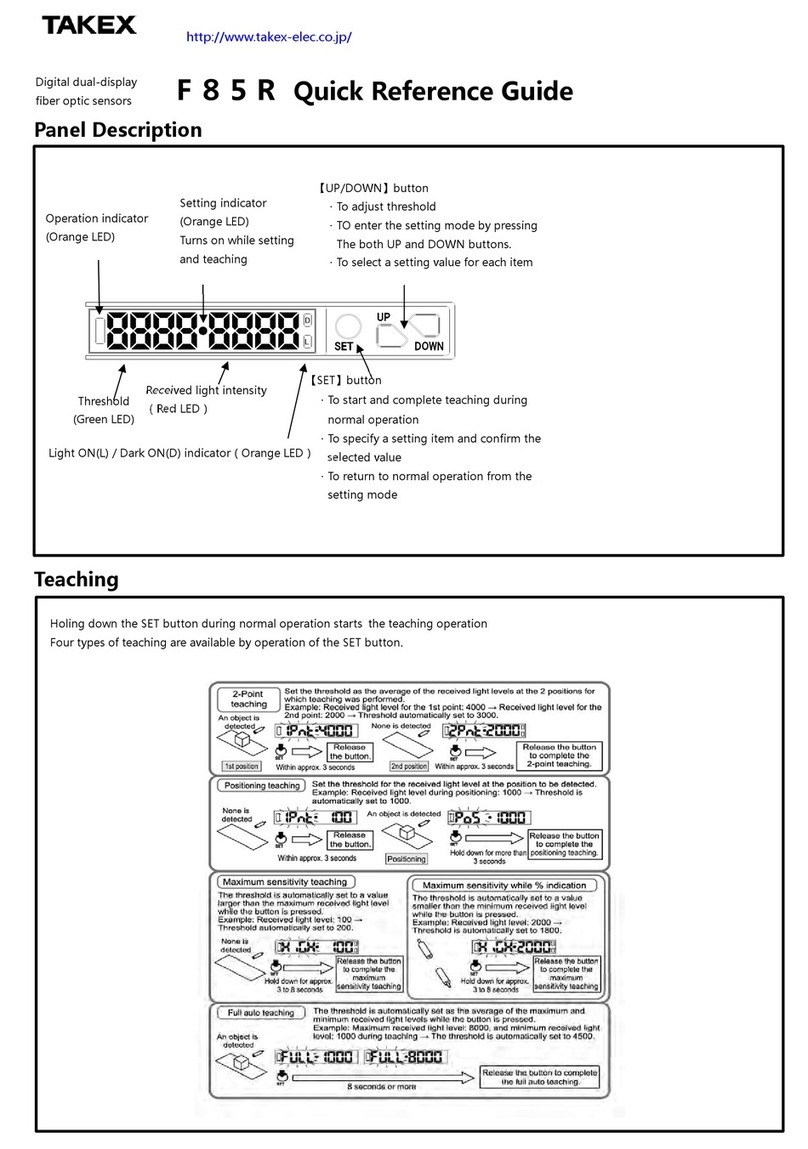

Leitungsabstand zwischen Infrarot-

schranken und Einbruchmeldezentrale

Installationshöhe

In den meisten Fällen ist es sinnvoll, den Strahl auf

einer Höhe von 70 bis 90cm zu installieren.

Beachten Sie die Strahlenausdehnung der einzelnen

Modelle, um eine eventuelle Reflexion auf dem

Untergrund oder auf in der Nähe stehenden Objekten

auszuschließen (siehe Tabelle

3

).

Montage

Die Schranken können einfach auf einem Mast oder

einer ebenen Oberfläche montiert werden.

- Ausrichtung über Drehspiegel

Über die Einstellscheibe und die Einstellschrauben

kann sich der Spiegel horizontal (±90°) und vertikal

(±10°) bewegen; dadurch ist ein Betrieb der

Schranken in alle Richtungen möglich.

Entfernen Sie die Abdeckung, indem Sie die

Schraube am unteren Teil der Abdeckung lösen.

6

E

Lösen Sie die Schrauben, mit denen die Schranken-

einheit auf der Montageplatte befestigt ist und lösen

Sie die Montageplatte, indem Sie sie nach unten

schieben.

6

B

Wandmontage

Bohren Sie Löcher in die Wand.

4

A

Setzen Sie die Montageplatte als Bohrschablone auf

die Wand und markieren Sie die Position der

Bohrlöcher. (Lassen Sie eine Fläche von 20mm

oberhalb und 25mm unterhalb der Platte frei.

Dadurch kann die Geräteabdeckung nach der

Montage leichter abgenommen werden.)

Führen Sie Vorbohrungen an der Wand durch.

4

B

Holzwand: 3mm Durchmesser.

Betonwand: Richten Sie sich nach den für den

verwendeten Dübel geltenden Angaben.

Installieren Sie die Schranke

4

C

Stecken Sie die Montageschrauben in die Bohrungen,

wobei ein 15 mm langes Stück der Schraube stehen

bleiben sollte.

Bringen Sie die Montageplatte auf den aus der Wand

ragenden Schrauben an.

Ziehen Sie die Leitung durch.

Ziehen Sie die Schrauben an.

Schließen Sie die Anschlussklemmen an.

Bringen Sie die Schrankenabdeckung an.

Schliessen Sie die Öffnung der Leitungs-

durchführung, um ein Eindringen von Insekten zu

vermeiden.

4

C

Die Schranke kann nicht in einer Installationsdose

installiert werden.

Für die Zuleitungen ist die Verwendung einer

Installationsdose jedoch möglich.

Mastmontage

Bringen Sie eine Leitungsdurchführung am Mast an.

Ziehen Sie die Leitung durch.

5

A

- Das Gerät kann auf einem Mast mit einem

Außendurchmesser von 38 bis 45mm montiert

werden.

- Bringen Sie an der Stelle des Mastes, an der die

Schranke angebracht werden soll, ein Loch mit

einem Durchmesser von 13mm für die Zuleitungen

an.

Entfernen Sie um die Öffnung herum alle Bohrspäne

und scharfen Kanten mit einer Feile, um eine

Beschädigung der Kabel zu verhindern.

Auch eine Gummidurchführung kann verwendet

werden, wenn dies gewünscht wird.

Montieren Sie die Schranke am Mast.

5

B

Bringen Sie die U-Klammern am Mast an und

befestigen Sie sie mit Schrauben an der

Montageplatte.

Befestigen Sie die Schrankeneinheit.

Ziehen Sie die Leitung durch.

Schließen Sie die Anschlussklemmen an.

Bringen Sie die Abdeckungen an. (Brechen Sie die

gestanzten Öffnungen an der Schrankenabdeckung

und der Mastabdeckung entsprechend dem

Mastdurchmesser und der Mastanordung auf.)

Schrankenanordnung Rückseite an Rückseite am

Mast

5

C

Bringen Sie an den Masten vier U-Klammern zu je

zwei Paaren an, ein Paar jeweils oberhalb des

anderen, ausgerichtet in die entgegen gesetzte

Richtung (siehe Abbildung).

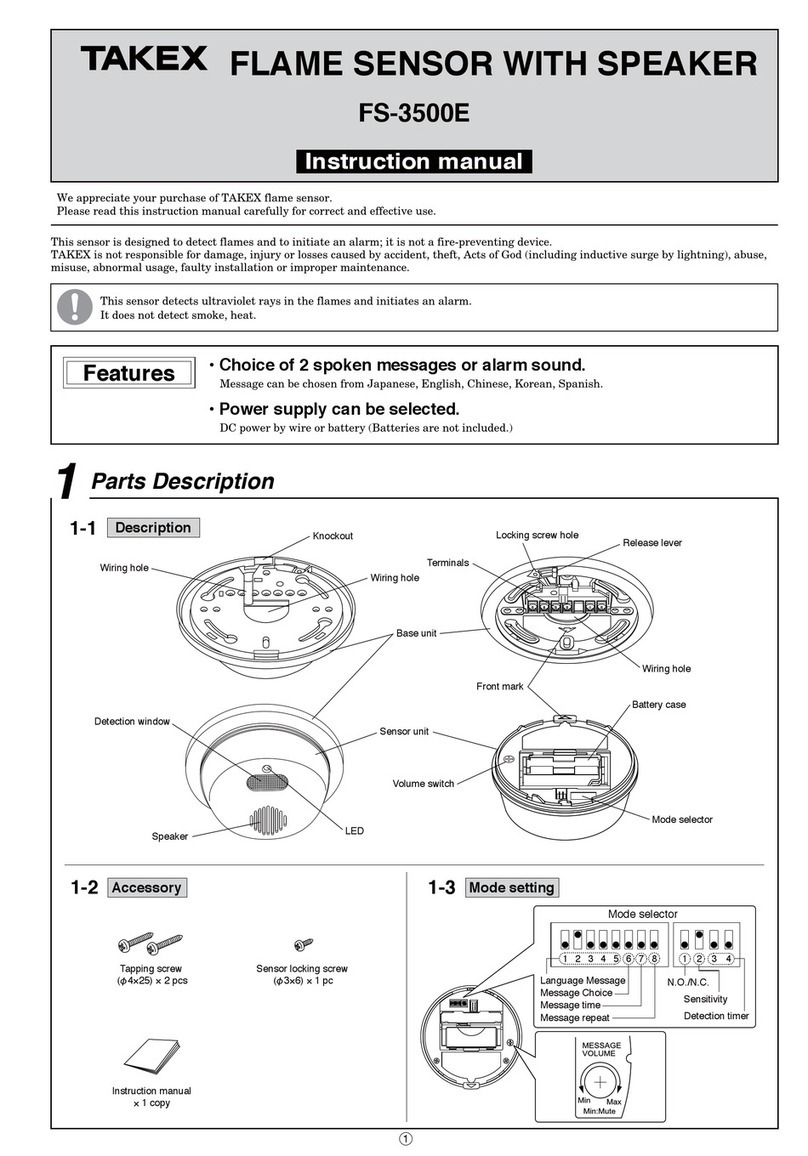

Montageanleitung PB-50FA / PB-100FA / PB-200FA

Die Schranke ist dafür bestimmt, unbefugtes Eindringen

festzustellen und einen Alarm auszulösen; es handelt

sich dabei nicht um eine einbruchhemmende Vorrichtung.

TAKEX übernimmt keine Haftung für Schäden oder

Verletzungen, die durch Unfall, Diebstahl, höhere Gewalt

(einschließlich Überspannungen durch Blitzschlag),

Missbrauch, falschen Gebrauch, unsachgemäßen Gebrauch,

falsche Montage oder fehlerhafte Wartung entstehen.

Die Aktiv-Infrarotschranke von TAKEX (PB-50FA,

PB-100FA und PB-200FA) besteht aus einem

Infrarotsender und –empfänger.

Die Schranke ist für eine UND-Schaltung ausgelegt – ein

Alarm wird nur dann ausgelöst, wenn die vier (übereinander)

angeordneten Strahlen gleichzeitig unterbrochen werden.

Es wird kein Alarm ausgelöst, wenn Insekten oder fallende

Blätter nur bis zu drei Strahlen unterbrechen.

Darüber hinaus kann zwischen vier

Durch die programmierte automatische

Verstärkungsregelung wird die Empfindlichkeit bei

schlechtem Wetter automatisch erhöht; Nebel, Regen oder

Frost stellen für die Aktiv-Infrarotschranke deshalb kein

Problem dar.

PB-50FA 12V 24V

AWG20 (ø0.8 mm) 244m 1,710m

AWG18 (ø1.0 mm) 381m 2,680m

AWG17 (ø1.1 mm) 457m 3,200m

AWG16 (ø1.25 mm) 595m 4,000m

AWG15 (ø1.4 mm) 750m 5,180m

AWG14 (ø1.6 mm) 976m 6,860m

PB-100FA 12V 24V

AWG20 (ø0.8 mm) 200m 1,550m

AWG18 (ø1.0 mm) 335m 2,410m

AWG17 (ø1.1 mm) 400m 2,930m

AWG16 (ø1.25 mm) 534m 3,660m

AWG15 (ø1.4 mm) 670m 4,730m

AWG14 (ø1.6 mm) 884m 6,000m

PB-200FA 12V 24V

AWG20 (ø0.8 mm) 192m 1,340m

AWG18 (ø1.0 mm) 300m 2,100m

AWG17 (ø1.1 mm) 366m 2,560m

AWG16 (ø1.25 mm) 473m 3,200m

AWG15 (ø1.4 mm) 595m 4,000m

AWG14 (ø1.6 mm) 777m 5,340m

Sind zwei oder mehr Schrankenpaare miteinander

verbunden, entspricht der maximale

Leitungsabstand dem oben angegebenen Wert geteilt

durch die Anzahl der Schrankenpaare.

Die Signalleitung kann mit I-Y(ST)Y Telefondraht

(Durchmesser 0.65mm) bis zu einem Abstand von

1,000m verlegt werden.

A - Abdeckung

B - Sucher

C - Spiegel

D - Einstellschraube für horizontale Feineinstellung

E - Einstellschraube für vertikale Ausrichtung

F - Anschlussklemmen

G - Schalter für Sabotageanzeige

H - Schlossschalter für die automatische

Verstärkungsregelung (nur Empfänger)

I - Funktionserklärungen (siehe R)

J - Spiegel

K - Einstellscheibe

L - Dämpfungsscheibe

M - Montageplatte

N - Befestigungsschelle

O - Vorgestanzte Öffnung

P - Abdeckung für Mastmontage

Q - Vorgestanzte Öffnung

R - Betriebsanzeige

S - Anzeige für Emp ndlichkeitsdämpfung

T - Alarmanzeige

U - Schalter für akustisches Ausrichtungssignal

(werkseitig auf OFF eingestellt)

V - Einstellung der Ansprechzeit (werkseitig auf 0,05

Sekunden eingestellt)

W - Buchse für Testgerät

X - Speicheranzeige-LED

Y - Einstellung für Alarmausgang (werkseitig auf N/C

eingestellt)

Z - Einstellung für Speicher (werkseitig auf AUS

eingestellt)