4

Caution

Do not apply impact to the unit.

Strong impact may result in performance deterioration

and/or damage to the unit.

The unit may not operate properly near devices that

generate a strong electric or magnetic field.

Also, devices near the unit may not operate properly

due to the magnetic field and/or magnetism generated

from the unit.

Make sure to confirm before operation.

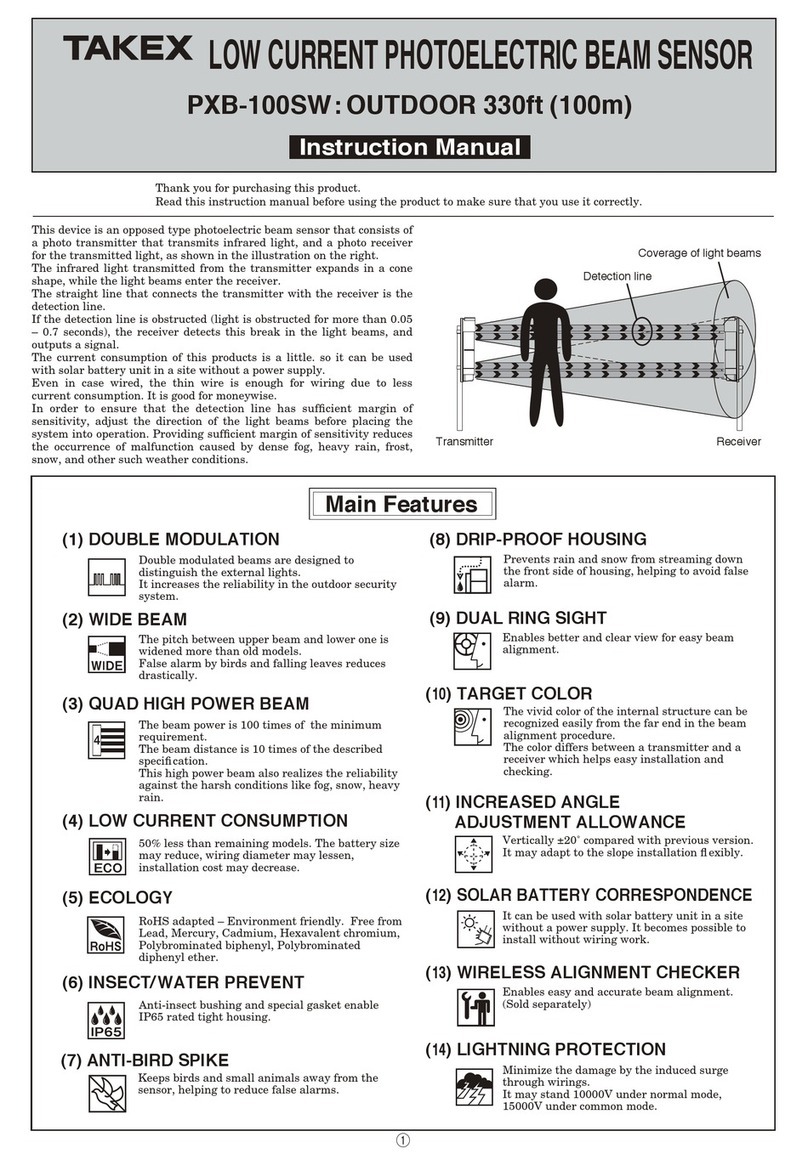

When branches, leaves of trees and weeds around the

detection line blow in the wind, they may interrupt the

detection line and result in false detection.

Periodically trim (cut) branches leaves, and weeds.

Vine plants may entwine the unit when growing, which

may result in false detection.

Periodically trim them.

For multi-level protection, use the upper and lower

sensors with the same rated protection distance, and

set the same frequency channel for both sensors.

Failure to follow this could result in false and/or

non-detection.

Securely conduct installation work according to the

instruction manual.

Also, make sure to use the supplied accessories and

specified components.

Failure to follow this may result in injury and/or

property damage in the event of fire, electric shock or

fall of the unit.

Install the unit straight so that it does not look inclined

from the front.

Make sure to perform a sufficient operation check on

the whole system before operation.

Do not use the transmitter and receiver of different

model numbers together.

Failure to follow this could result in false and/or

non-detection.

Do not use models other than this series (TXF-125E) on

the extention of the same detection line.

Failure to follow this could result in false and/or

non-detection due to interference between the sensors.

Do not install the unit in places subject to oil smoke,

steam, high humidity, and/or a lot of dust.

Electricity that travels through these substances may

result in fire, electric shock, and/or false operation.

Avoid mounting, battery connection, and battery

replacement where humidity is high.

Humidity may enter the unit and generates

condensation, which could result in malfunction.

Do not touch connector sections and batteries with wet

hands, which could result in electric shock and/or

corrosion.

Make sure that batteries are not heated, when

removing them.

Use the lithium-metal primary batteries for this unit.

Handle them as dangerous goods for transport by air,

observing the IATA Dangerous Goods Regulations in

terms of packing, marking and labeling.

When disposing batteries, observe regulations in force

of each country.

For replacement of batteries, use the batteries specified

in the instruction manual.

If you use different batteries, specified performance will

not be met.

The battery life is just a reference when used at the

normal temperature, and it is not the guaranteed

value.

Before actual installation, perform a sufficient

operation check in a place of operation and confirm that

the receiver can clearly receive the beams.

Installing the unit in location where direct sunlight,

headlight of vehicle, IR illumination or LED light

directly enter the optical axis may result in false and /

or non-detection.

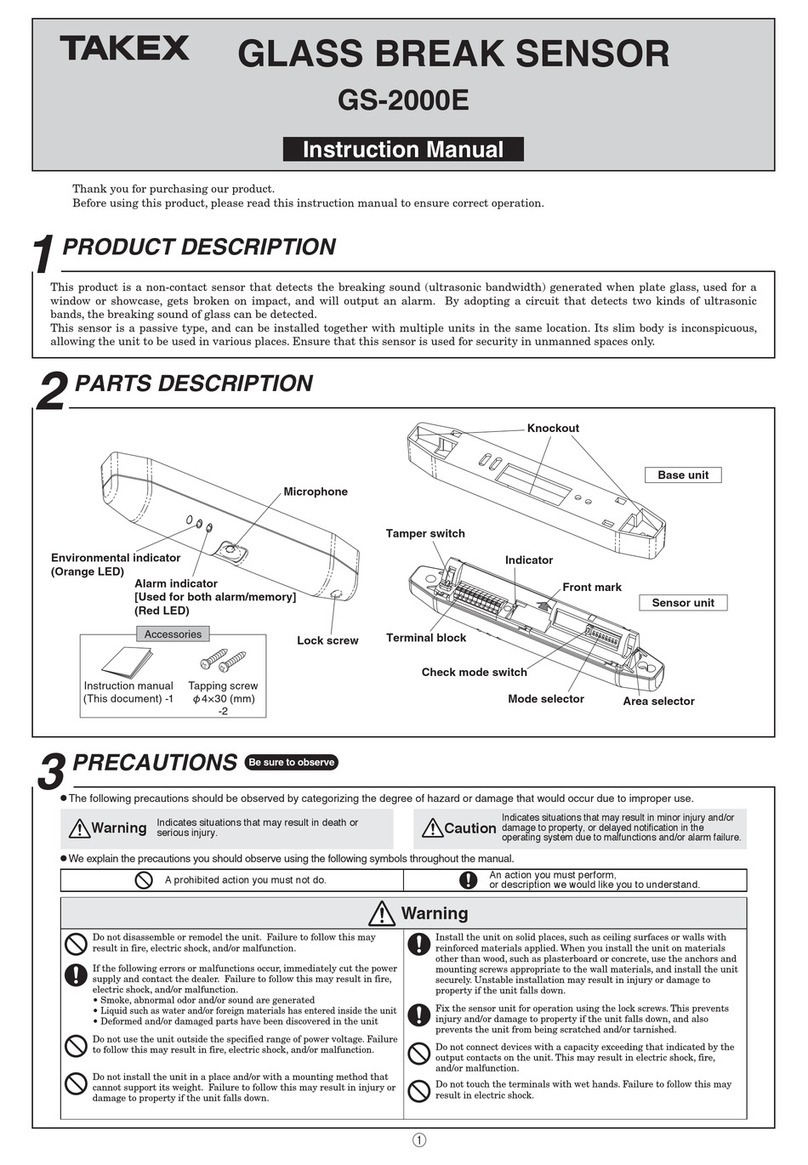

Installing the unit in the following places may result in

false and/or non-detection.

s0LACESSHIELDEDBYTREES

s0LACESWHERETHEREARELIGHTREFLECTINGOBJECTSONTHE

ground on the optical axis

s0LACESWHEREMOVINGOBJECTSSUCHASLAUNDRYSHIELD

the light in the optical axis

s0LACESTHATAREUNSTABLEANDPRONETOVIBRATION

s5NEVENPLACES

s0LACESSUBJECTTOPOLLUTEDWATERSEAWATERANDOR

chemicals

s0LACESWHERESMALLANIMALSMAYPASSSUCHAS

directly above fences

s0LACESCLOSETOFENCES

s)NCLINEDORHORIZONTALINSTALLATION

• Installation in areas where

moving objects (the laundry etc)

can obstruct the optical axis •Installation on uneven

ground

• Slanted installation • Installation close to a wall

• Installation directly

above a wall

• Installation in an

unstable, wobbling

location

TXF-125E-KH

Models other than

TXF-125E-KH

•Installation in locations

shaded by trees etc.

•Using TXF-125E-KH

together with other

models

• Installation in locations where

the device may be splashed by

dirty water or direct sea spray.

Installation so that the LED light does not

enter into the optical axis of beam sensor.

Installing IR illumination overlapping

detection line of beam sensor.

Installation in location where strong light such as

sunlight or light from vehicle headlights can directly

enter the optical axis.

Installation so that the LED light illuminates

transmitter side, where LED light is required.

Installing the LED light so that it looks down

from high mounted position, separated form

the optical axis of receiver where LED lights

in parallel with detection line.

Installation so that the optical axis(Receiver)

is adjusted toward an opposite direction of

road, when detection line is set in parallel

with road.