©2011 Tyco Electronics Corporation, a TE Connectivity Ltd. Company

All Rights Reserved

*Trademark

TE Connectivity, TE connectivity (logo), and TE (logo) are trademarks. Other logos, product and/or Company names may be trademarks of their respective owners.

1of 4

Instruction Sheet

TOOLING ASSISTANCE CENTER

1-800-722-1111

PRODUCT INFORMATION

1-800-522-6752

This controlled document is subject to change.

For latest revision and Regional Customer Service,

visit our website at www.te.com LOC B

408-9007

AMP-HDI* High Density

Interconnection Printed Circuit

(PC) Board Connectors 18 AUG 11 Rev A

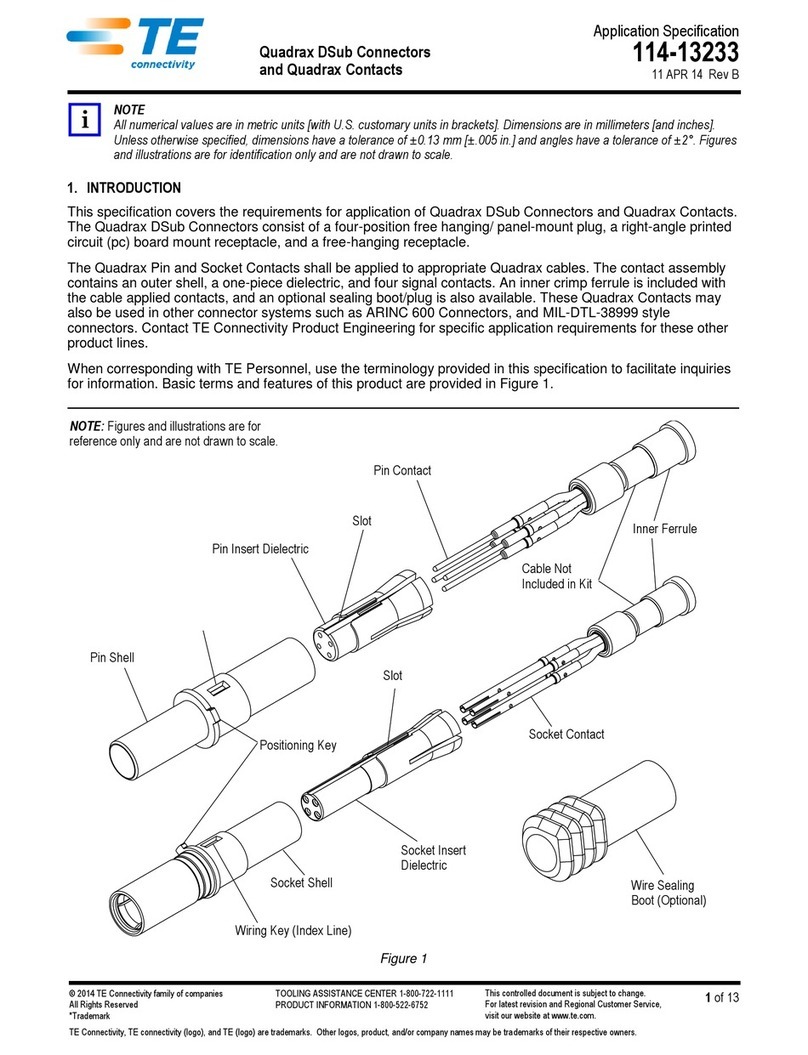

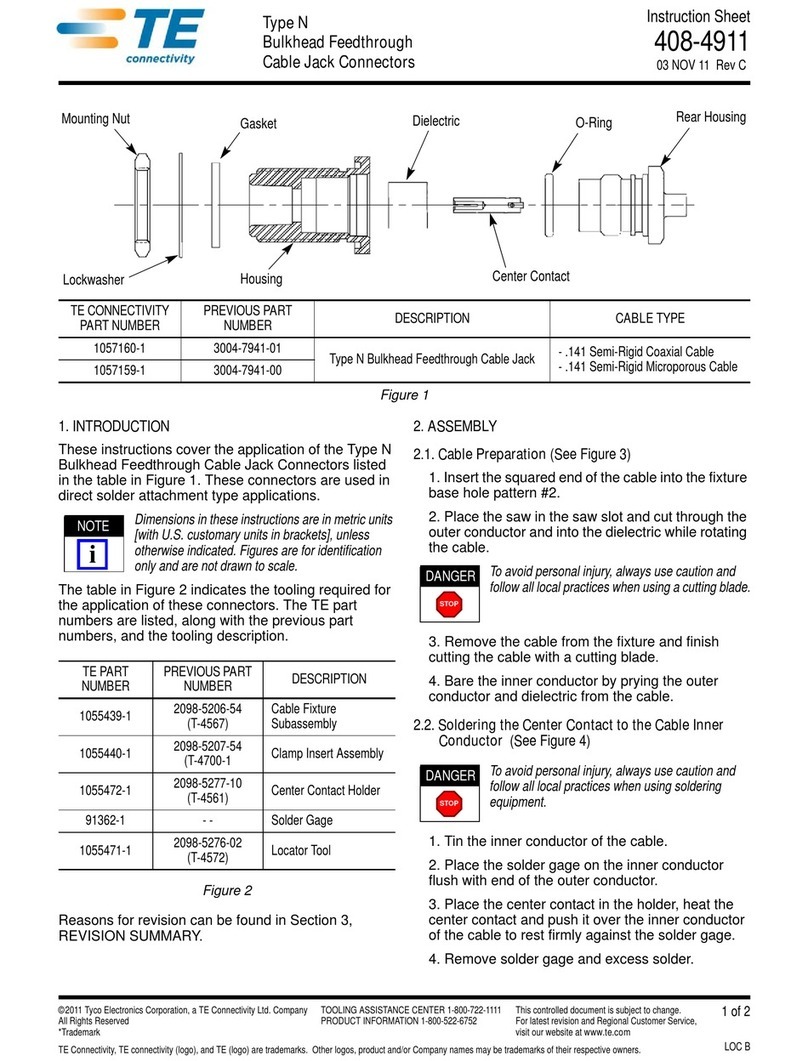

Figure 1

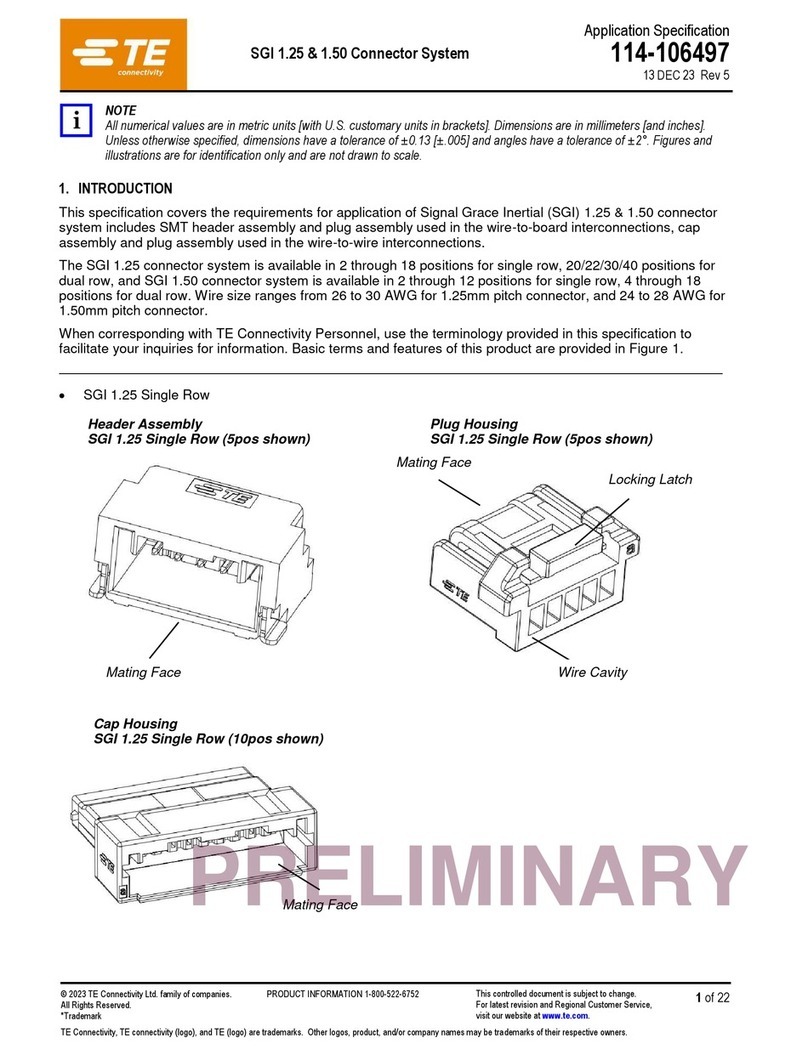

1. INTRODUCTION

This instruction sheet covers the contacts,

accessories, mounting procedures, and pc board

layout dimensions recommended for the AMP-HDI

connectors listed in Figure 1.

Read these instructions carefully before installing or

assembling the connectors.

Figures and illustrations are for reference only and

are not drawn to scale.

2. DESCRIPTION

AMP-HDI pin and receptacle connectors are available

with two, three, or four rows of contacts, on a .100-in.

grid, totaling a maximum of 684 positions.

The connectors feature pin headers with ACTION

PIN* contacts; four-point, box-type receptacle

contacts; and a 64-combination keying arrangement.

One or two guide pins are used to facilitate reliable

mating of long connectors.

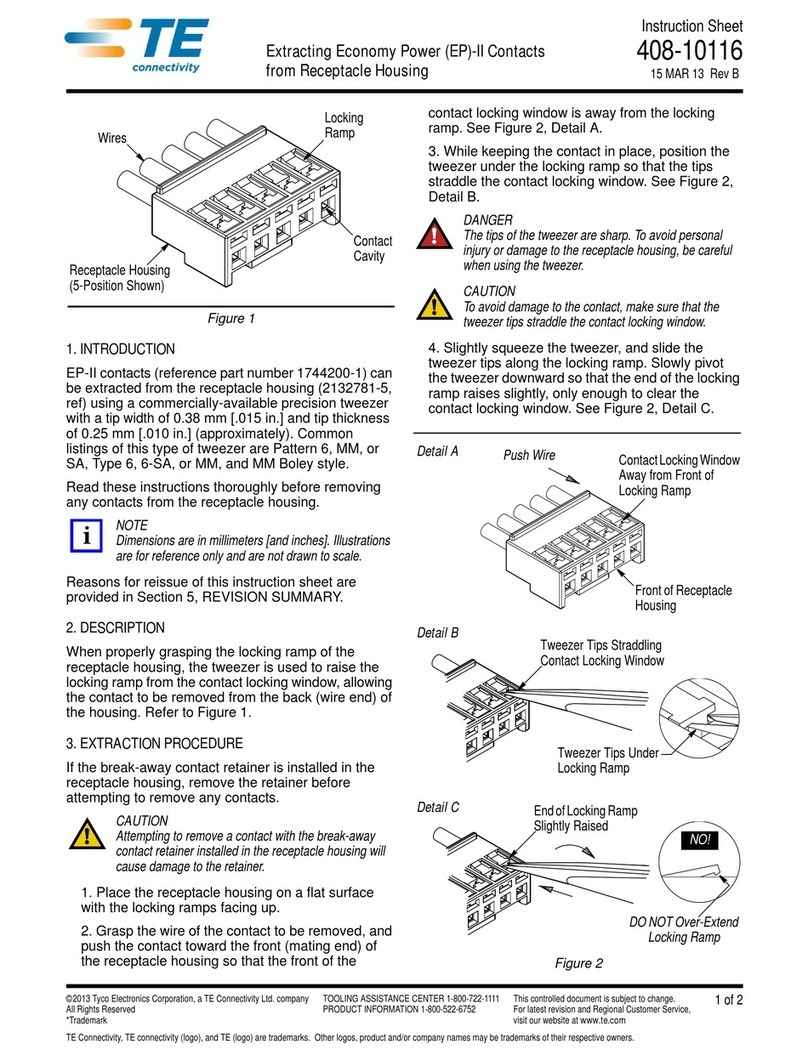

3. INSTALLING AMP-HDI CONNECTORS

3.1. Pin Connectors

When installing a pin connector into a pc board,

use of an insertion fixture is recommended to

protect the posts of the ACTION PIN contacts and

to support the connector and pc board in the

machine base. The insertion fixture is designed by

the customer for the specific connector size.

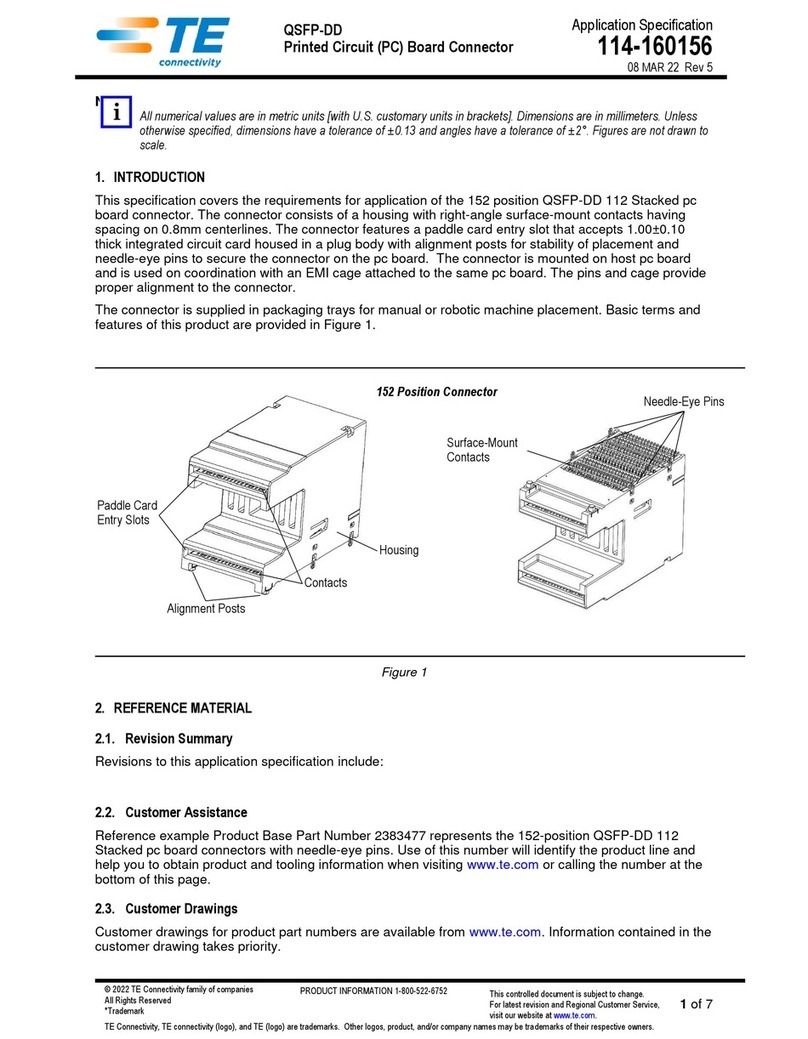

The connectors can be inserted into the pc board by

using the insertion tool listed in Figure 2 and by using

a power unit which is required for larger connectors

and larger pc boards.

Proceed as follows:

1. Place the pc board on top of the insertion fixture.

2. Align pc board holes with insertion fixture holes,

and loosely press connector contact posts through

holes in pc board and insertion fixture.

3. Select the appropriate insertion tool, and position

the tool in the top of the connector. See Figure 2.

4. Adjust the power unit to correct shut-height.

Receptacle

Connector

Guide Pin

PinConnector

(4-Row)

CONNECTORS

TYPE PART NUMBER

4-Row Pin 532435, 532448, 532818, 532837, 532841, 532921, 532933, 533056, 533254, 533270, 533404

Receptacle 532434, 532840, 532903, 532920

3-Row Pin 532432, 532438, 532447, 532839, 532919, 533061, 533092, 533093, 533094, 533294, 533296

Receptacle 532431, 532838, 532918, 533268

2-Row Pin 532429, 532446, 533060, 533090, 533091

Receptacle 532428, 532825