N3 Drive Operations Manual

Table of Contents

Table of Contents

1.0 Introduction.....................................................................................................................................1

2.0 Product Inspection.........................................................................................................................2

2.1 Nameplate Layout ......................................................................................................................2

3.0 Operating Precautions...................................................................................................................3

3.1 Before Power up.........................................................................................................................3

3.2 During Power up.........................................................................................................................4

3.3 Before Operation ........................................................................................................................4

3.4 During Operation ........................................................................................................................5

4.0 Environment and Installation ........................................................................................................6

4.1 Inverter Mounting........................................................................................................................6

Fig.4.1.1 Panel and Enclosure Placement .....................................................................................6

Fig 4.1.2 Din Rail Mounting Clearances.........................................................................................7

5.0 General Wiring Diagram (1 - 2 HP)................................................................................................8

6.0 General Wiring Diagram (3 - 75 HP)..............................................................................................9

7.0 Power Terminals Designations and Ratings (Terminal Block TM1)........................................10

7.1 Power Terminal Configuration TM1..........................................................................................10

7.2 Power Terminal Block TM1 Electrical Ratings and Tightening Torques..................................11

8.0 Inverter Wiring ..............................................................................................................................11

8.1 Input / Output Power Wiring Connections (Terminal TM1) ......................................................11

8.2 Input / Output Power Wiring Noise Suppression......................................................................11

Fig. 8.2 Input / Output Power Wiring Noise Suppression.............................................................11

8.3 Motor Cable Length..................................................................................................................12

8.4 Cable Length vs Carrier Frequency .........................................................................................12

8.5 Inverter Grounding....................................................................................................................12

8.6 Input Power Wiring and Installation Recommendations with Examples ..................................13

Fig. 8.6 Input Power Wiring and Installation Examples................................................................13

9.0 Input / Output Power Section Block Diagram............................................................................14

Fig. 9.0 Power Input / Output Block Diagrams.............................................................................14

10.0 Control Terminals (Terminal Block TM2) .................................................................................15

10.1 Control Terminal Designations (Terminal Block TM2) ..........................................................15

10.2 Control Terminal Layout and Control Switches.....................................................................16

Fig. 10.2.1 Control Terminal TM2 Layout................................................................................16

Fig. 10.2.2 Control Terminal TM2 Layout (Prior to Version 1.3) .............................................16

10.3 Control Terminal Wiring and Connections (Terminal TM2)..................................................16

11.0 Peripheral Power Devices..........................................................................................................17

12.0 Input Fuse Types and Ratings ...........................................................................................18 - 19

13.0 Applicable specifications for circuit breakers and magnetic contactors.............................19

14.0 Reactor Input / Output Specifications ......................................................................................20

15.0 Braking Unit and Braking Resistor Selections........................................................................21

16.0 EMC Filters..................................................................................................................................22

17.0 Keypad Key Functions and Navigation....................................................................................23

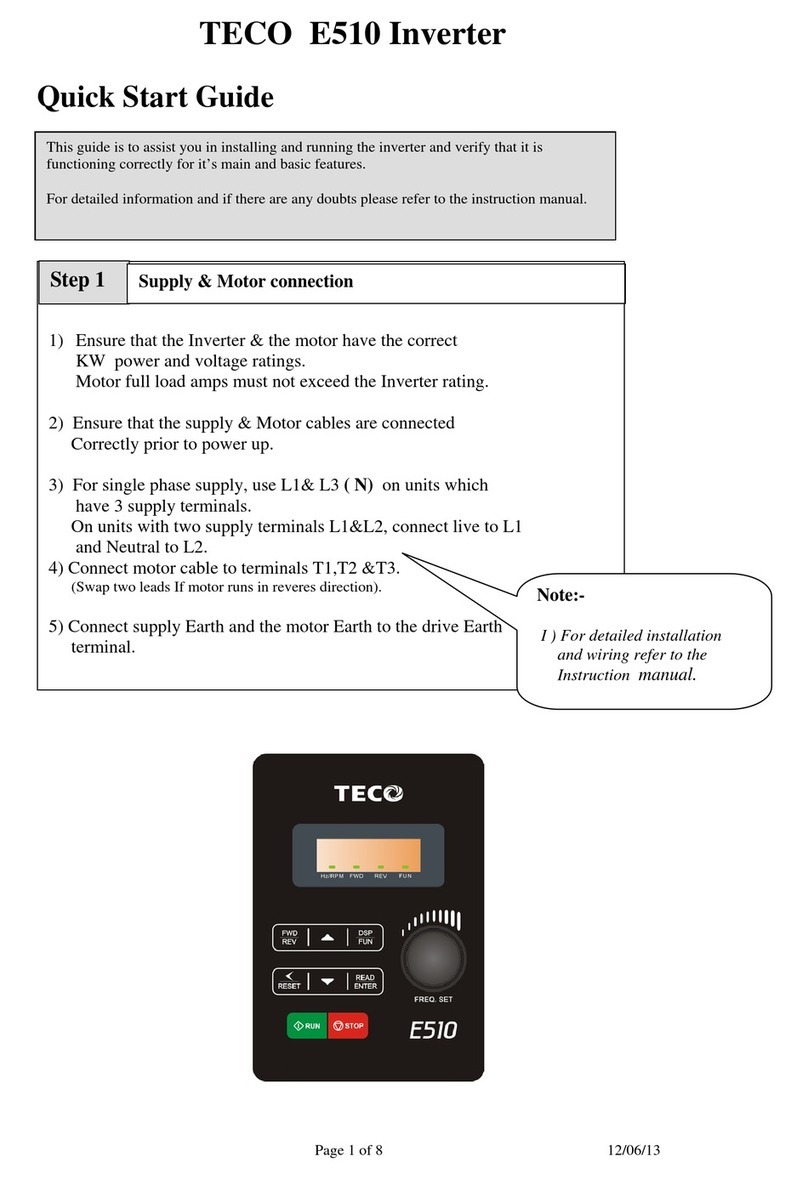

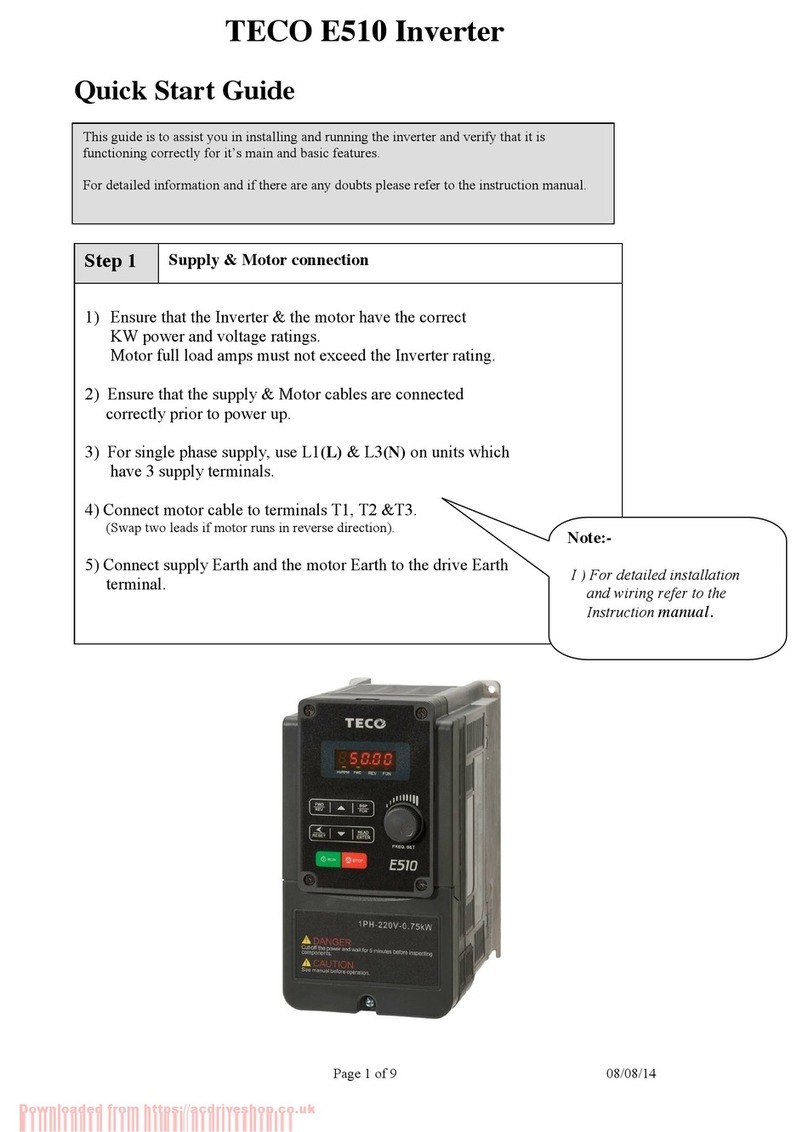

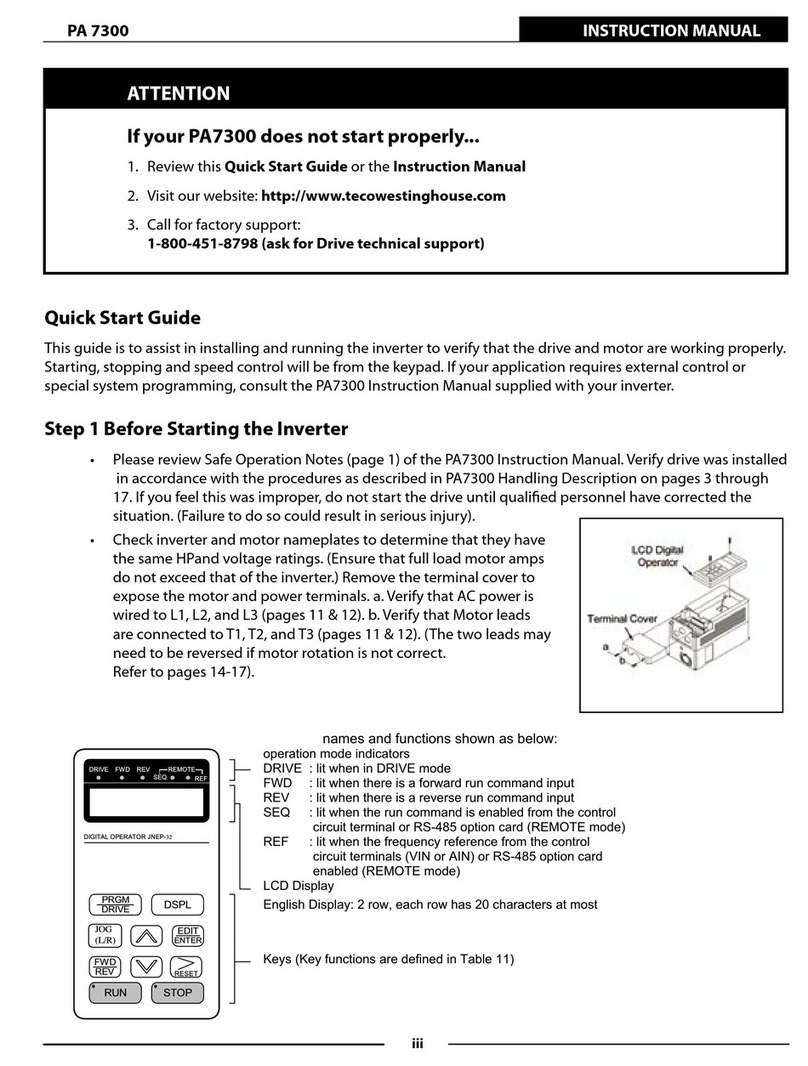

17.1 N3 Keypad.............................................................................................................................23

17.2 Keypad LED Functions..........................................................................................................23

17.3 Key Functions........................................................................................................................24

17.4 Keypad Navigation ................................................................................................................25

17.4.1 Basic Keypad Control .................................................................................................25

17.4.2 Local / Remote Function..............................................................................................25

17.4.3 Setting Parameters b(Basic) and A(Advanced)........................................................26

18.0 Control Mode Selection .............................................................................................................27

Cont.