1 Contents

3

1Contents

1Contents ...................................................................................................3

2Safety and the environment....................................................................4

2.1. About this document........................................................................4

2.2. Ensure safety...................................................................................4

2.3. Protecting the environment..............................................................4

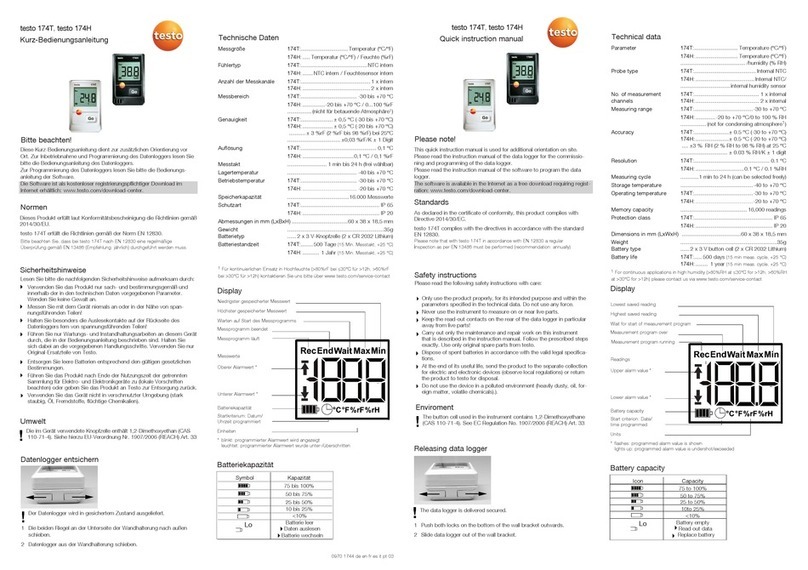

3Specifications ..........................................................................................5

3.1. Use ..................................................................................................5

3.2. Technical data .................................................................................5

4Product description...............................................................................13

4.1. Status LEDs...................................................................................13

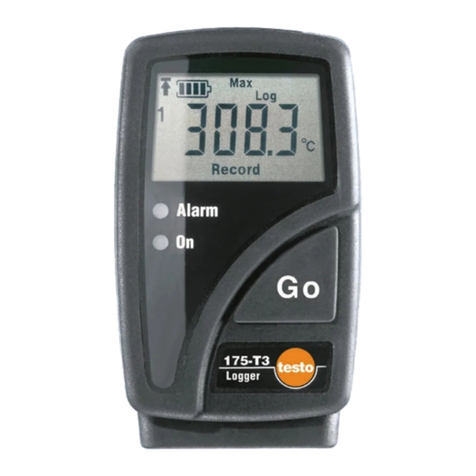

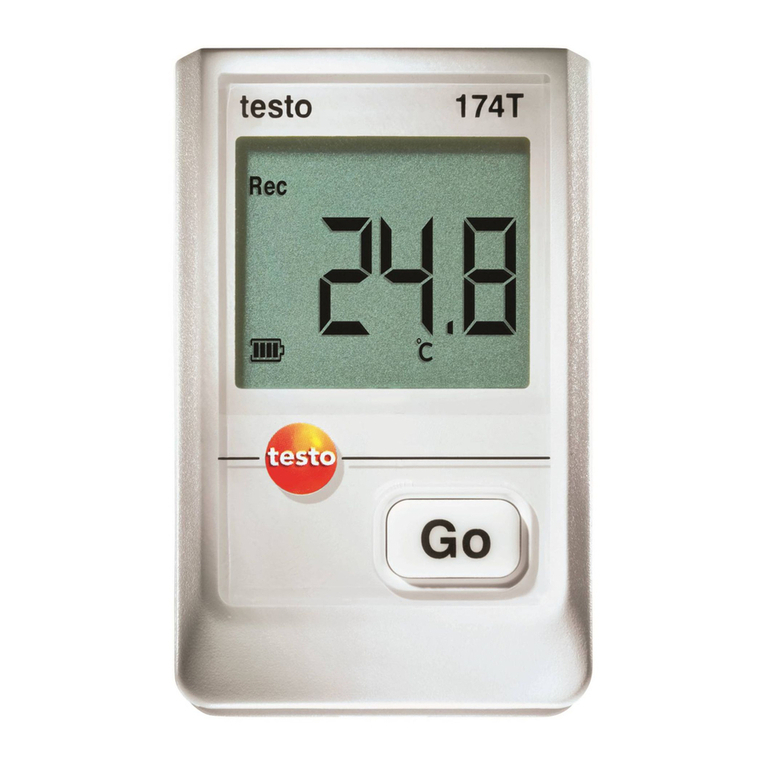

4.2. Display (LCD) ................................................................................14

4.3. Key functions.................................................................................15

4.4. Important information and glossary of terms..................................16

5Using the product..................................................................................19

5.1. Configuring the data logger ...........................................................19

5.2. Measuring......................................................................................21

5.3. Reading out data ...........................................................................21

6Maintaining the product........................................................................23

6.1. Changing the batteries ..................................................................23

6.2. Cleaning the instrument.................................................................24

7Tips and assistance...............................................................................25