1 Contents

3

1Contents

1Contents ...................................................................................................3

1.1. Technical data .................................................................................4

1.1.1. Measurement ranges and resolution................................................................4

1.1.2. Other instrument data ......................................................................................5

2Product description.................................................................................6

2.1. Control Unit......................................................................................6

2.1.1. Overview..........................................................................................................6

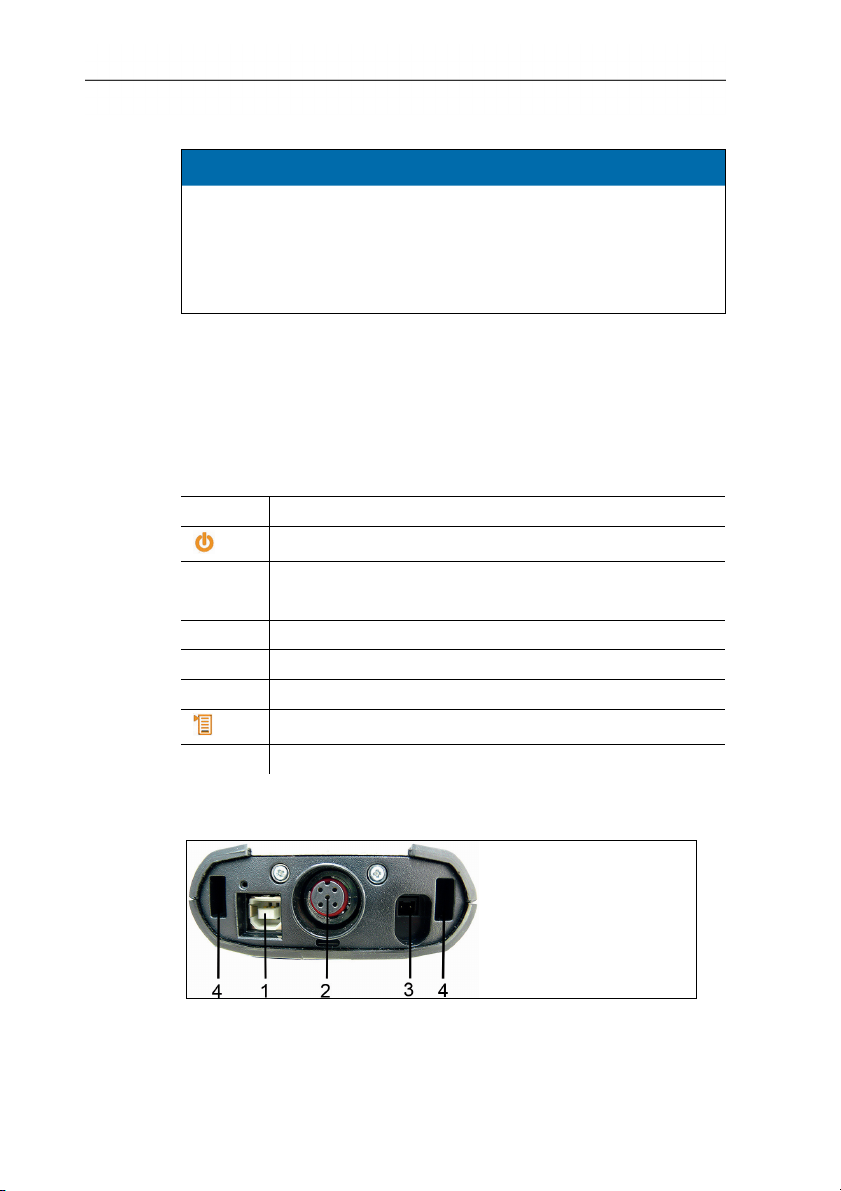

2.1.2. Keyboard .........................................................................................................7

2.1.3. Connections / interfaces ..................................................................................7

2.2. Meas. box........................................................................................8

2.2.1. Overview..........................................................................................................8

2.2.2. Status display ..................................................................................................9

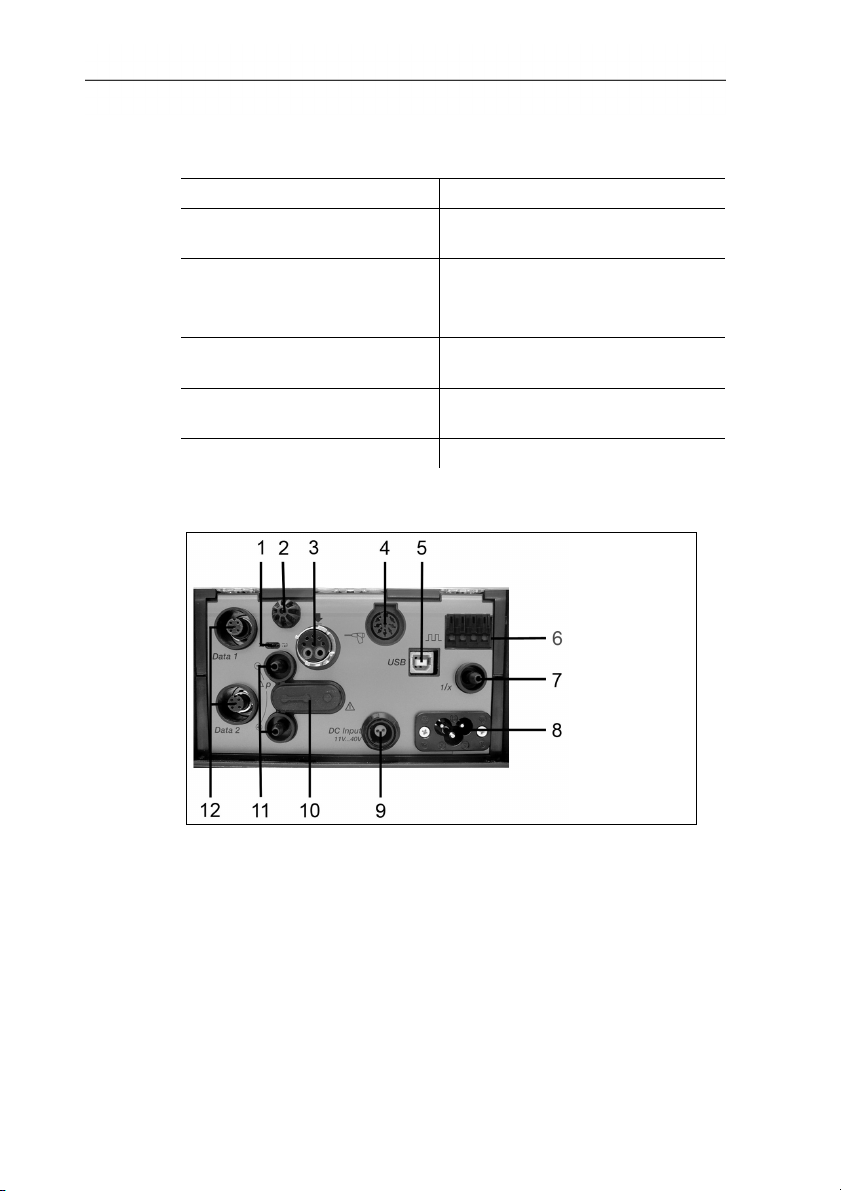

2.2.3. Connections / interfaces ..................................................................................9

2.2.4. Menu guidance meas. box............................................................................. 10

2.2.5. Modular flue gas probe ..................................................................................11

3First steps ..............................................................................................11

3.1. Commissioning ..............................................................................11

3.1.1. Control Unit.................................................................................................... 11

3.1.2. Meas. box ......................................................................................................12

3.2. Getting to know the product...........................................................13

3.2.1. Connecting probes / sensors .........................................................................13

3.2.2. Connecting system components ....................................................................13

3.2.2.1. Connection using contact strip.........................................................13

3.2.2.2. Connecting via Data bus cable (accessory).....................................13

3.2.2.3. Connection via Bluetooth®(option) ..................................................15

3.2.3. Switching on ..................................................................................................15

3.2.4. Printing / saving data .....................................................................................16

3.2.5. Switching off ..................................................................................................16

3.3. Folders / Locations ........................................................................17

4Using the product..................................................................................19

4.1. Performing settings........................................................................19

4.1.1. Assigning the right hand function key.............................................................19

4.1.2. Instrument settings ........................................................................................20

4.1.2.1. Measurement view ..........................................................................20

4.1.2.2. Date / time.......................................................................................22

4.1.3. Programs .......................................................................................................22

4.2. Measuring......................................................................................25

4.2.1. Preparing for measurement ...........................................................................25

4.2.2. Applications ...................................................................................................26