Rev A Nov 2017 Page 2

Chapter 1 Overview

For temperature sensi ng the TTC001 temperature controller works with both

thermistors and temperature IC sensors like the AD590 or AD592. With a thermistor

the temperature display is shown as resistance value in kΩ. If the TTC001 is operated

with a temperature sensor IC, the temperature is shown in °C or °F.

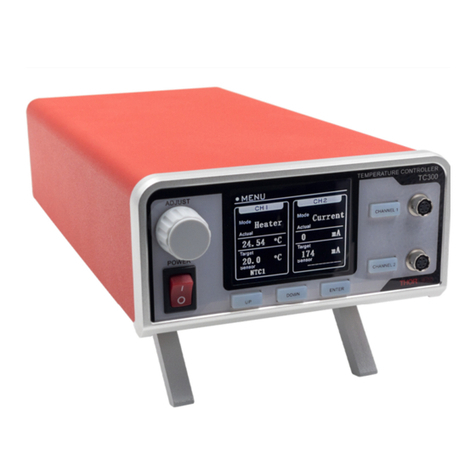

TEC current output can be enabled or disabled via the Enter button on the front panel.

The Mode button allows the user to access the setup menus. The front panel Control

Knob can be used to adjust the temperature setting as well as navigate the menu.

The temperature sensor and the TEC element are connected by a 15-pin D-sub jack

at the rear of the unit. A 15-pin D-sub to 9-pin D-sub is supplied with the TTC001 to

directly connect to Thorlabs LDM56, LDM90, LDM21 and LM14S2 TEC mounts.

The set value of the temperature can be changed with the Control Knob on the front

panel or through the provide software when connected through the USB port. Also,

an analog input can be used to set the set point temperature or to directly control the

output current level. The temperature set point option will scale the input from the

lower temperature limit to the upper temperature limit. Th ese limits are set in the

Setup Menu. For current control, the input will scale to the current limit also set in the

setup menu.

The unit has been designed for safe operation with environmental temperatures up to

40 °C provided that a free air circulation through the ventilation slots at the rear and

at both sides of the unit is maintained.

USB connectivity provides easy Plug and Play PC controlled operation - multiple units

can be connected to a single PC via standard USB hub technology or by using the K-

Cube Controller Hub (see Section 3.2.4.) for multi-axis motion control applications.

Coupling this with the user friendly Kinesis™ software (supplied) allows the user to

get up and runn ing in a short space of time. Advanced custom motion control

applications and sequences are also possible using the extensive programming

environment also supplied. This programming library is co mpatible with ma ny

development tools such a s LabView, Visual Basic, Visual C++, C++ Builder,

LabWindows/CVI, Matlab and Delphi.

See Section 1.4. for a full description of the Kinesis software.

In the remainder of this handbook, the Tutorial section (Chapter 5) provides a good

initial understanding on using the unit, and the reference section (Chapter 6) covers

all operating modes and parameters in detail.

1.2 TEC Element Protection

The temperature control system includes a protective ci rcuit, which limits the TEC

current in all operating modes.

The current limit can be set through the menu system via the front panel, and through

software method calls. The TTC001 has a maximum current limit of ±1 A but this can

be limited to a minimum of ±100 mA. To access this feature press the Mode button,

Adjust the Control Knob until "Cur L" appears, Press the Enter button, use the Control

Knob to select the desired limit, and press Enter to accept.