Titan TM45FG User manual

Other Titan Power Tools manuals

Titan

Titan LX-70 User manual

Titan

Titan TTB935HTG User manual

Titan

Titan TTB591ROU Installation manual

Titan

Titan SF1022 Installation manual

Titan

Titan TTI882MLT User manual

Titan

Titan EHS User manual

Titan

Titan TTI913TOR User manual

Titan

Titan SF800XPL Installation manual

Titan

Titan TTB924DBT User manual

Titan

Titan SF1500XP Installation manual

Titan

Titan TS005V2 User manual

Titan

Titan TTK587GD0 Installation manual

Titan

Titan TTB285JSW User manual

Titan

Titan TT5MTP26-2 User manual

Titan

Titan CAPSpray 0524000 User manual

Titan

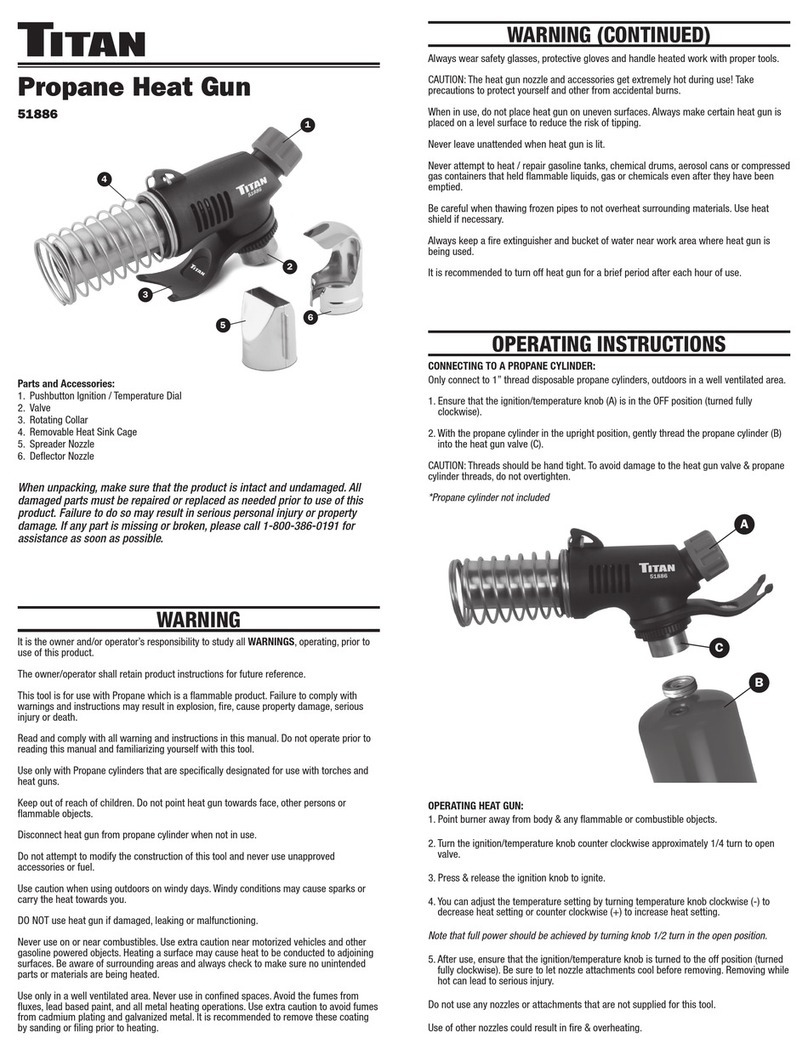

Titan 51886 User manual

Titan

Titan TTB883ROU User manual

Titan

Titan TTB284HTG Installation manual

Titan

Titan TTB280DRH Installation manual

Titan

Titan TT5MTP33BP-2 User manual