TonerRellKits.com RechargX™ RX167 v2

Mon - Fri 8am - 5pm ET © 1995-2011 ReChargX™, EmptyX, TonerRellKits and TonerRellKits.com, the TonerRellKits logo, the 2011.11.14

800.527.3712 or 352.343.7533 ReChargX™ and EmptyX logos are trademarks owned by TonerRellkits, LLC. All rights reserved. Page 3 of 9

Step 5: Plug in the Hole-Making Tool

Plug in the hole-making tool included with the

ReChargX™ Tool Kit.

Turn the sand timer over and wait the full three

minutes before using the tool so it reaches

proper operating temperature; this ensures the

tool will easily penetrate the cartridge housing

(gure 6).

Step 6: Creating the Toner Hopper Hole

Hold the ReChargX™ hole-making tool directly

over the location for the hole and press the

copper hole-making bit against the cartridge

allowing the heat of the tool to create the hole

(there is no need to use excessive force, let

the tool do the work with a minimal amount of

pressure) (gure 7).

NOTE: Once the copper tip of the hole-making tool

slowly penetrates the top of the toner cartridge,

immediately withdraw the tool and unplug it from

the wall.

Step 7: Remove the Excess Plastic From

the Hole-Making Tool

U

se the metal tip of the small at-blade

screwdriver, included in the ReChargX™ Tool

Kit, to remove the small, circular piece of

plastic that will normally remain inside the

copper hole-making bit (gure 8).

NOTE: This step needs to be completed before

the hole-making tool cools off. If the plastic

does harden inside the copper bit, plug in the

tool and remove the plastic debris as soon as it

starts to loosen from the bit.

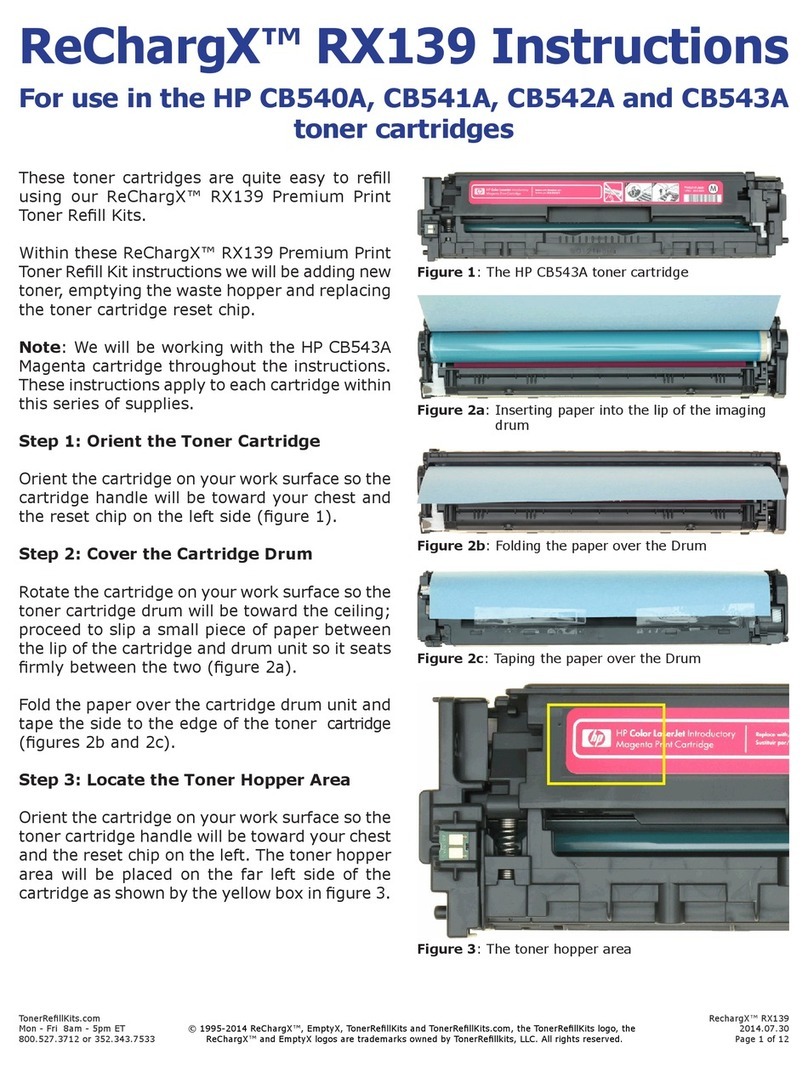

Figure 6: Wait for the hole-making tool to warm up

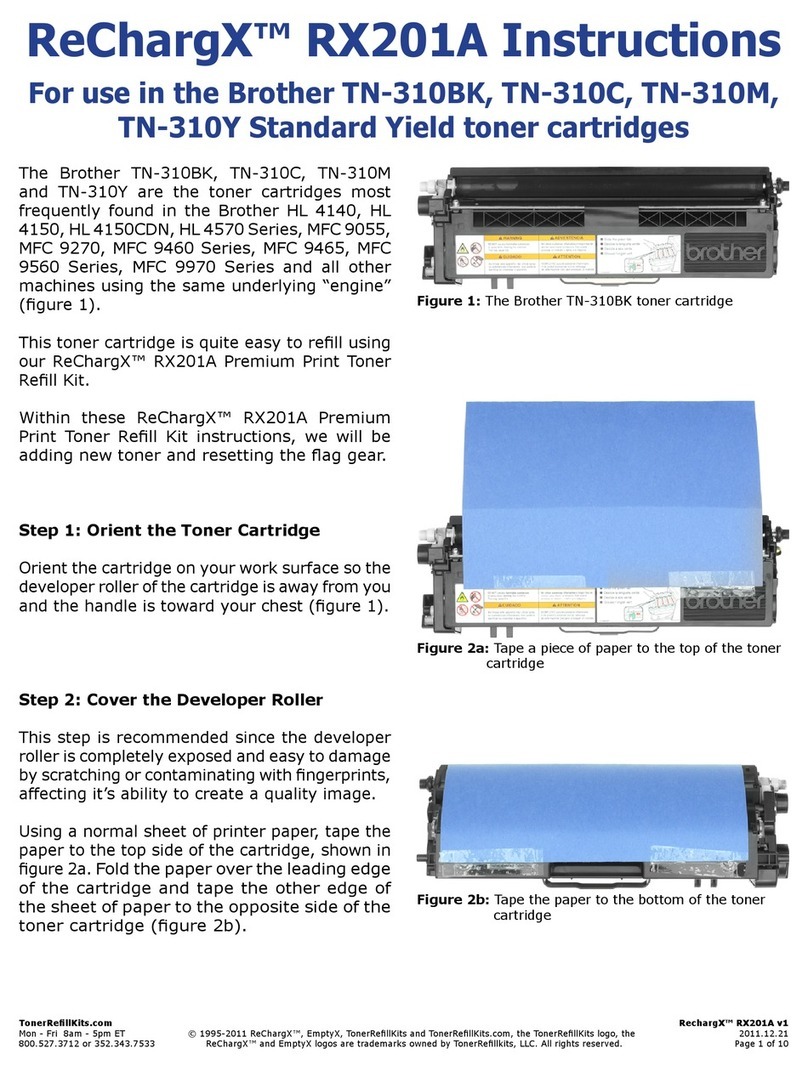

Figure 7: Create the toner hopper hole

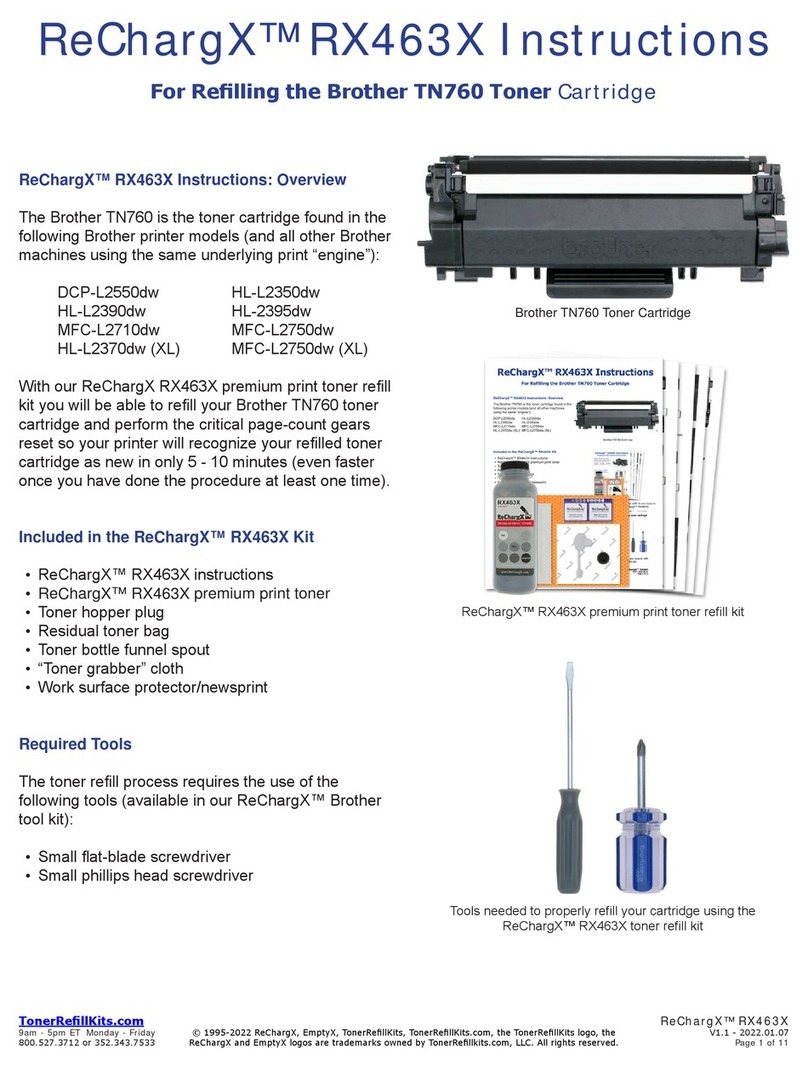

Figure 8: Remove the excess plastic from the tip of the

hole-making tool