OPERATIONAL INSTRUCITONS

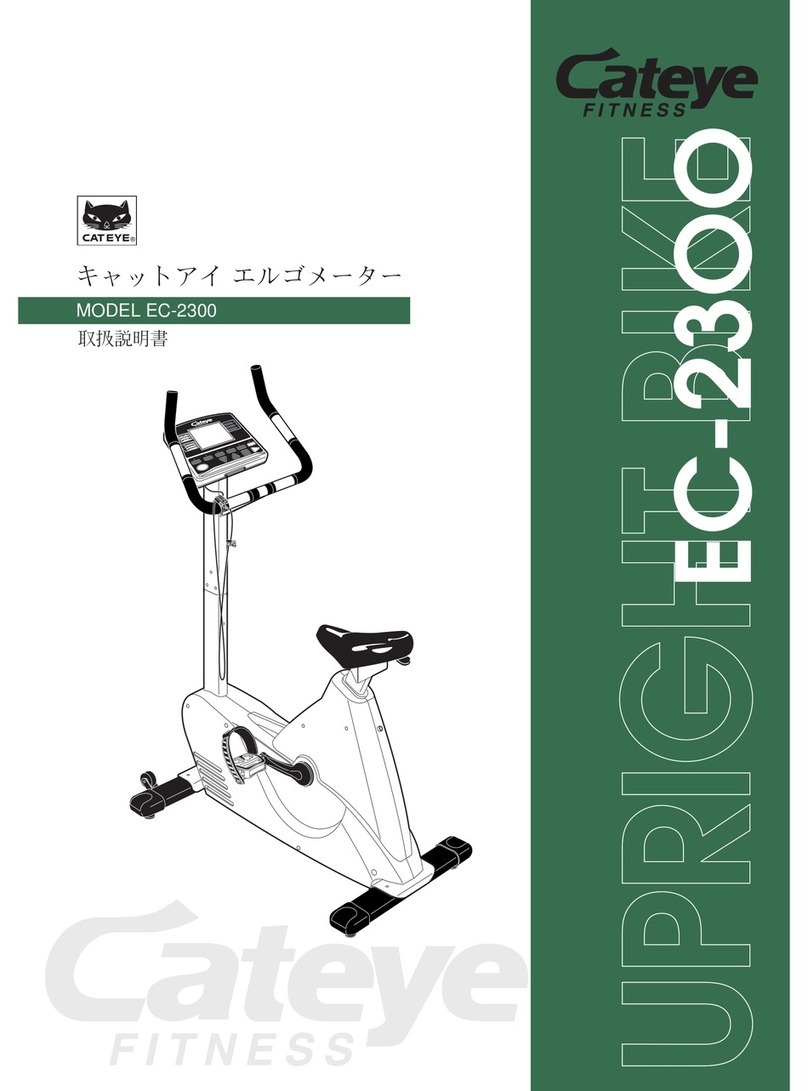

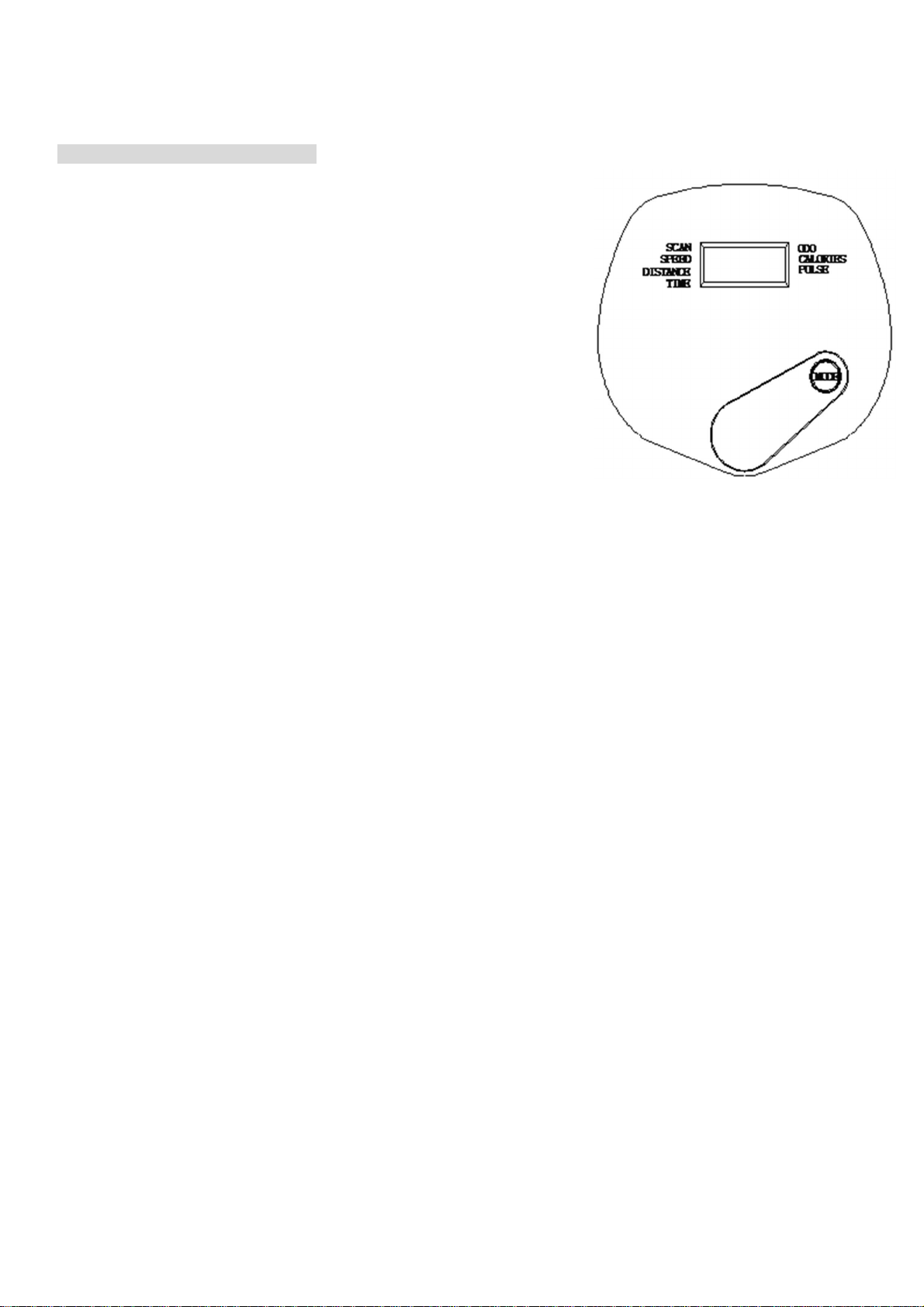

USING THE FITNESS METER

POWER ON: Pedal movement or press the button.

POWER OFF: Automatically shuts off after four minutes of inactivity.

MODE BUTTON:

Press to select display functions, including SCAN, TIME, SPEED,

DISTANCE,

CALORIES, ODOMETER, and PULSE.

Press and hold for two seconds to reset all functions to zero, except

ODOMETER.

FUNCTIONS:

SCAN: Automatically scans each function of TIME, SPEED, DISTANCE, CALORIES,

ODOMETER, and PULSE in sequence, display changes every six seconds. Press and release the button

until “SCAN” appears on the display.

TIME: Displays the time from one second up to 99:59 minutes.

SPEED: Displays the current speed from zero to 999.99 KM.

DISTANCE: Displays the distance from zero to 99.99 KM.

CALORIES: Displays the calories burned from zero to 999.9 Kcal. The calorie readout is an estimate for an

average user. It should be used only as a comparison between workouts on this unit.

ODOMETER: Displays the total accumulated distance you have traveled from zero to 999.9 KM. The total

accumulated distance is retained when the meter is turned off.

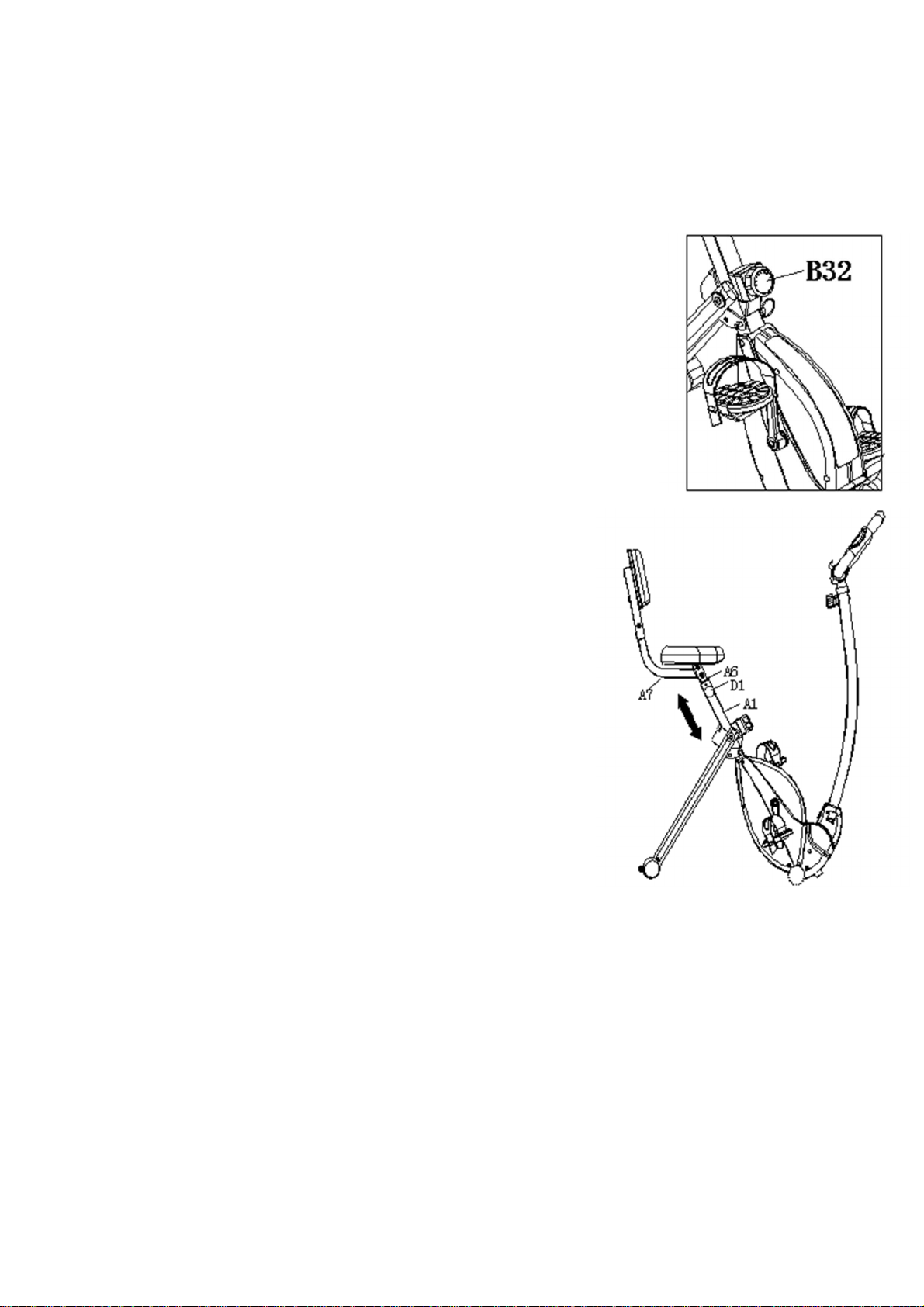

PULSE: Displays your pulse rate in beats per minute. To display pulse, select the PULSE mode and grasp

the pulse sensors on the handlebar, one in each hand. The heart icon will begin flashing when the

FITNESS METER senses your pulse. Your pulse will be displayed approximately five (5) seconds after the

heart icon is displayed. If the heart icon does not appear, relax your grip or change your grip on the pulse

sensors.

NOTE: 1. The meter will shut off automatically after four minutes of inactivity. All function values will be

kept. Press the button and hold it down for two seconds to reset all functions to zero, except ODOMETER.

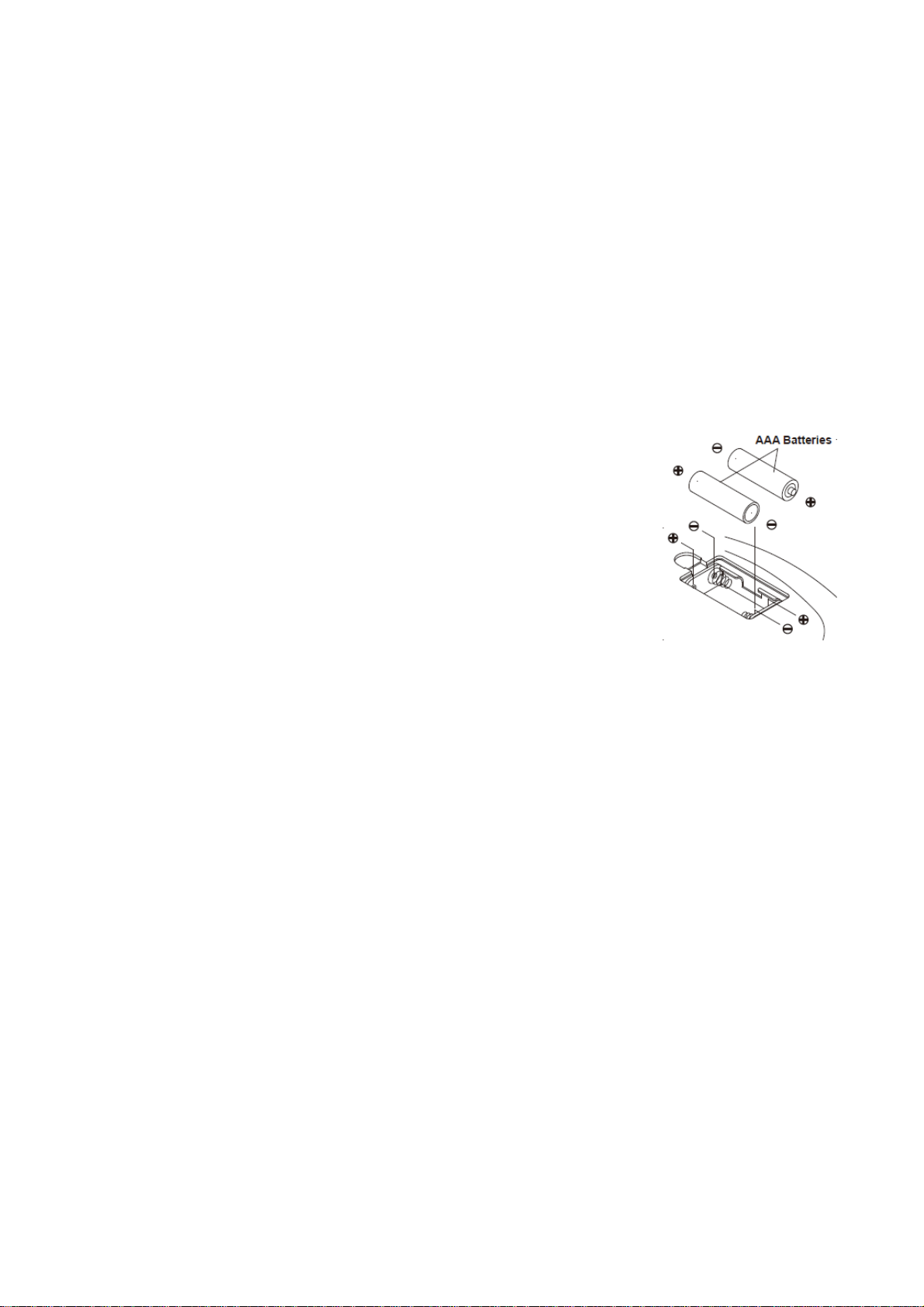

2.The ODOMETER will be reset to zero after batteries are removed for battery replacement or storage of

the unit.