Contents

Safety.......................................................................4

GeneralSafety...................................................4

SafetyandInstructionalDecals..........................5

Setup........................................................................8

1InstallingtheSteeringWheel(International

ModelsOnly)...................................................8

2CheckingtheFluidLevelsandTire

Pressure.........................................................8

3BurnishingtheBrakes......................................9

4ReadingtheManualandViewingthe

SetupMaterial.................................................9

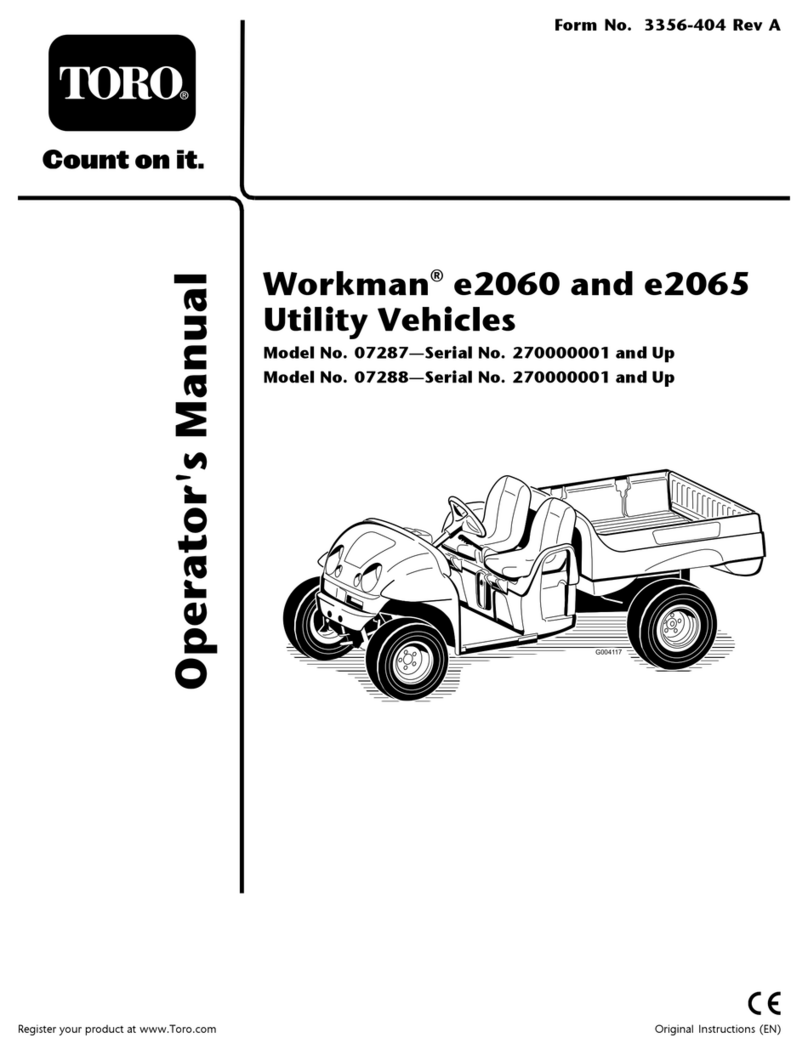

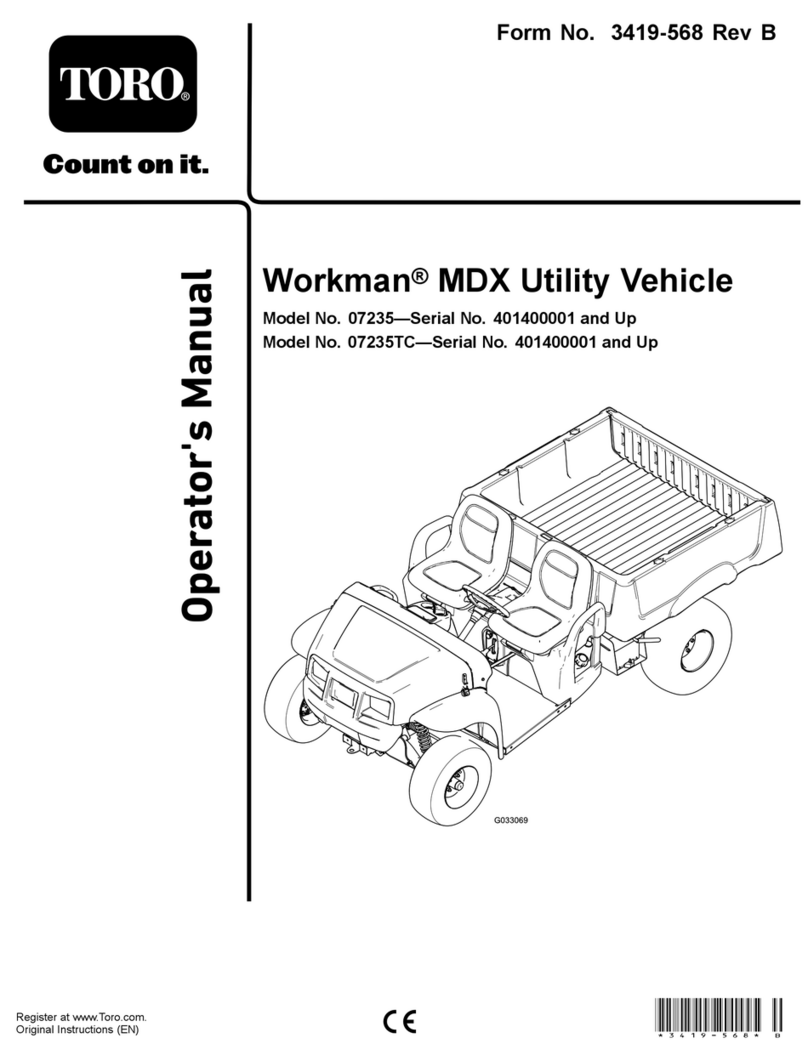

ProductOverview...................................................10

Controls...........................................................10

Specications..................................................13

Attachments/Accessories.................................13

BeforeOperation.................................................14

BeforeOperationSafety...................................14

PerformingDailyMaintenance..........................14

CheckingtheTirePressure...............................14

UnderstandingandUsingtheBattery

System..........................................................15

BreakinginaNewMachine..............................16

DuringOperation.................................................17

DuringOperationSafety...................................17

OperatingtheCargoBed..................................18

UsingtheRearCargoBedAccessory

Mount............................................................21

StoppingtheMachine.......................................21

LoadingtheCargoBed.....................................21

AfterOperation....................................................22

AfterOperationSafety......................................22

HaulingtheMachine.........................................22

TowingtheMachine..........................................23

TowingaTrailer................................................23

Maintenance...........................................................24

MaintenanceSafety..........................................24

RecommendedMaintenanceSchedule(s)...........24

DailyMaintenanceChecklist.............................25

MaintainingtheMachineunderSpecial

OperatingConditions....................................26

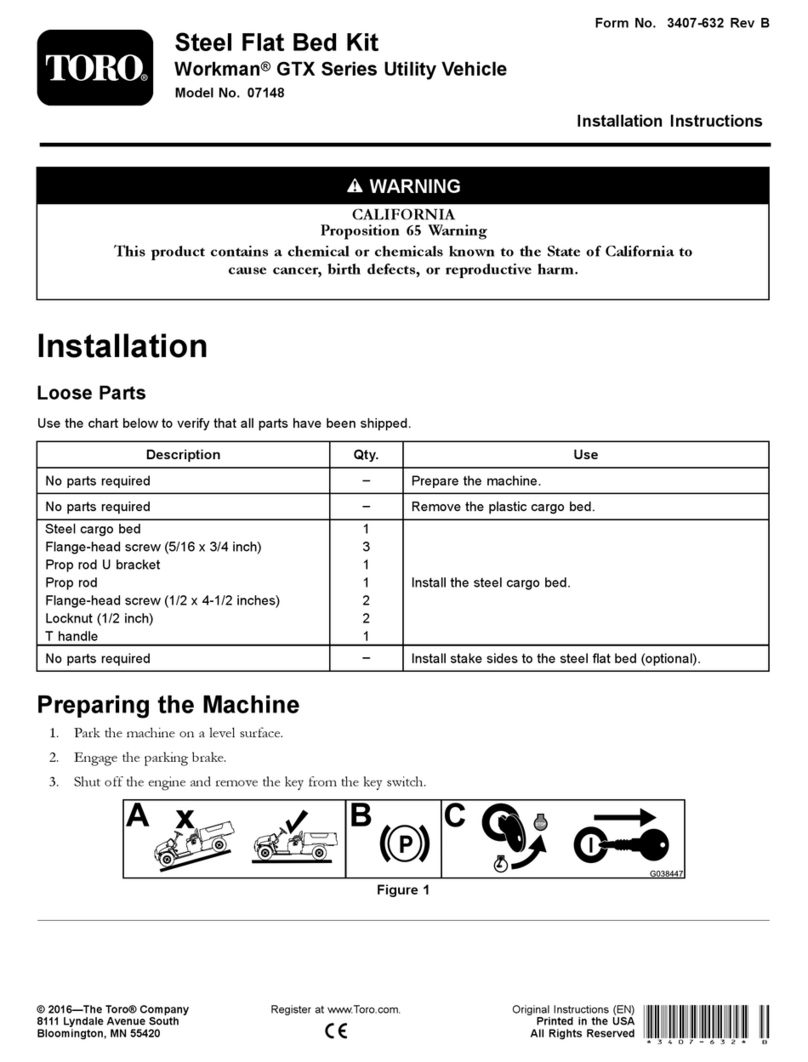

Pre-MaintenanceProcedures..............................26

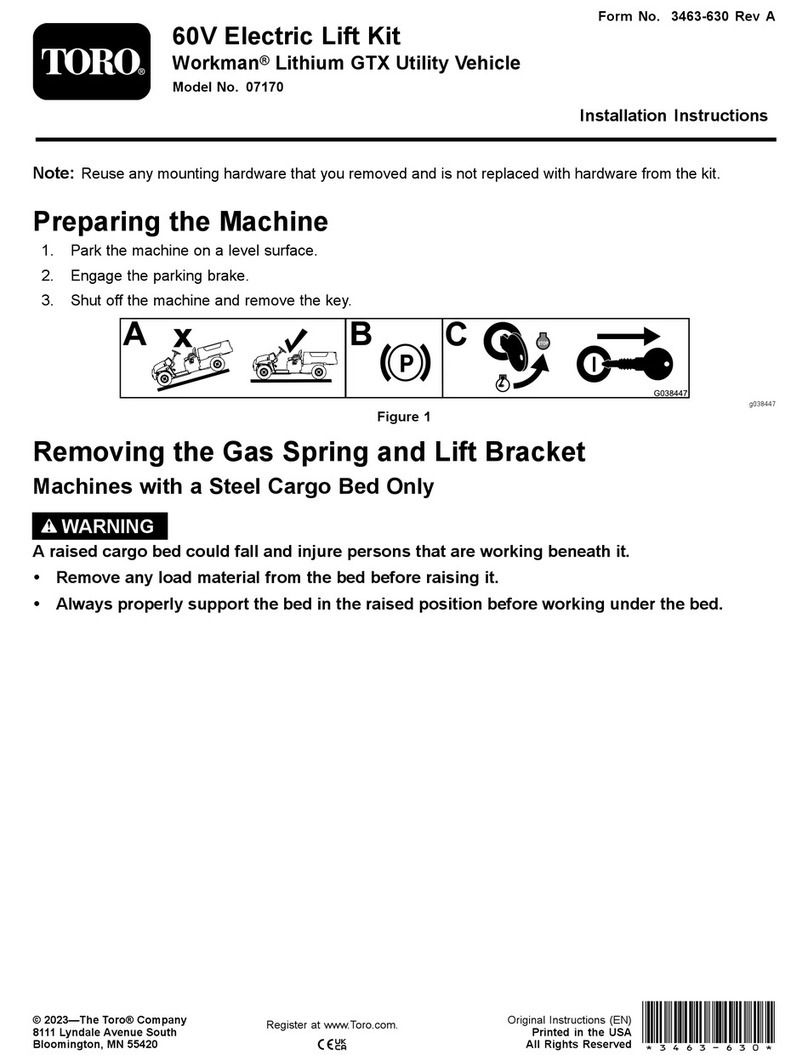

PreparingtheMachineforMaintenance............26

LiftingtheMachine...........................................27

AccessingtheHood..........................................27

RaisingandLoweringtheSeat

Assembly......................................................28

RemovingaBucketSeat..................................28

InstallingaBucketSeat....................................28

RemovingaBenchCushion.............................28

InstallingaBenchCushion...............................29

Lubrication..........................................................29

GreasingtheFrontWheelBearings..................29

ElectricalSystemMaintenance...........................32

ElectricalSystemSafety...................................32

BatterySafety...................................................32

MaintainingtheBatteries..................................33

ReplacingtheFuses.........................................38

MaintainingtheHeadlights...............................38

DriveSystemMaintenance..................................39

MaintainingtheTires........................................39

InspectingtheSteeringandSuspension

Components.................................................40

AdjustingtheFrontWheelAlignment................40

CheckingtheTransaxle-FluidLevel..................41

ChangingtheTransaxleFluid...........................42

BrakeMaintenance.............................................42

CheckingtheParkingBrake.............................42

AdjustingtheParkingBrake..............................42

CheckingtheBrake-FluidLevel........................43

InspectingtheBrakes.......................................43

ReplacingtheServiceandParking-Brake

Pads..............................................................44

ChangingtheBrakeFluid.................................44

ChassisMaintenance...........................................44

AdjustingtheCargo-BedLatches.....................44

Cleaning..............................................................45

WashingtheMachine.......................................45

Storage...................................................................46

StorageSafety..................................................46

StoringtheMachine..........................................46

Troubleshooting......................................................47

3