............ www.truemfg.com ............

True Food Service Equipment, Inc.

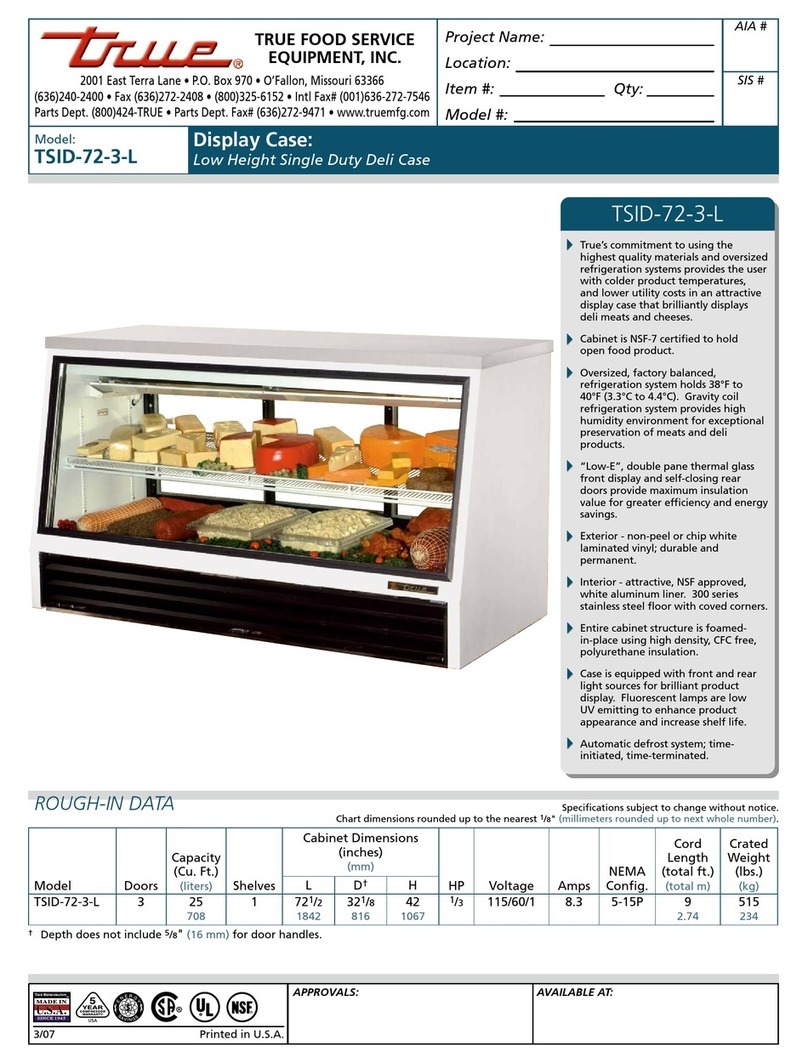

66

INSTALLATION / OPERATION INSTRUCTIONS

DEFROST TIME CLOCK OPERATION

(GRASSLIN TIMER)

RECOMMENDED DEFROST SETTINGS:

TRUEManufacturinghasfactorysetyour

defrosttimeclocktoarecommendedtime

anddurationdefrostscenario.Allunits

willrequireroutinedefrosts.YourTRUE

equipmenthasbeendesignedforthree

defrostperiods(6:00a.m.,2:00p.m.and

10:00p.m.).Ifyoudecidetodeviatefrom

thesedefrosttimesettingspleasefollowthe

proceduresforadjustmentbelow.

NOTE

Defrost timer will need to be set at current

time of day before plugging unit into power

supply.

REQUIRED TOOLS:

• PhillipsScrewdriver

• 1/4"NutDriverorSocket

Locating The Defrost Timer:

Defrosttimerislocatedinthelowerright

cornerbehindthelouveredgrill(inside

galvanizedelectricalbox).

Takeofflouveredgrillassemblyby

removingfour(4)cornerscrews.

Setting the timer:

(UNPLUG UNIT FROM

POWER SUPPLY!)

DO NOT SET THE TIME BY ROTATING THE

“OUTER” DIAL.

Turntheminutehandclockwiseuntilthe

timeofdayontheouterdialisalignedwith

thetrianglemarkerontheinnerdial(two

o’clockposition).

Adjusting The Defrost Timer:

(timeinitiated,timeortemperature

terminated)

YourTRUEequipmentcontainsadefrost

systemthatistemperatureterminated,

howeverthetimeclockhasbeendesigned

withatimeterminationback-upsothat

thedefrostperiodwillnotexceedthirty

minutes.WhileTRUErequiresaminimum

3defrostperiodsnottoexceed60minutes

theprocedureonthispageshouldbe

followedtocustomizeyourspecificneeds.

NOTICE

Iftimerisnotsetforaminimumof3

defrostperdayfor60minuteseach,thecoil

maydevelopexcessivefrost.Thismaylead

tosystemfailureandproductloss,whichis

notcoveredunderwarranty.

The following procedure may be followed

to customize your needs.

High usage, high temperature, and high

humidity may require 4 defrost settings

per day.

WARNING

Always follow the manufacturer’s

recommended settings when programming

the amount and duration of the defrost cycles.

STEP 1

Thewhitetabslocatedontheoutmostarea

ofthetimeclockhavebeenfactorysetfor

(6:00a.m.,2:00p.m.,and10:00p.m.).

Eachtabrepresents15minutesofdefrost

time.Noticethatateachdefrosttimefour

whitetabsaresetfor15minuteseachfora

totalof60minutesofdefrost.

STEP 2

Inordertoprogramthetimetobeginthe

defrostcycle,flipthewhitetabsouttoset

thedefrosttime.Toeliminateadefrosttime

flipthewhitetabsbacktowardthecenterof

theDefrostTimer.

STEP 3

TRUErecommendsa60minutedefrost

cyclethreetimesperday.

Outer most dial. White tabs

represent 15 minutes of

defrost time.

Time of day.

Inner most dial.

Defrost Timer Image 2

Defrost Timer Box Image 1