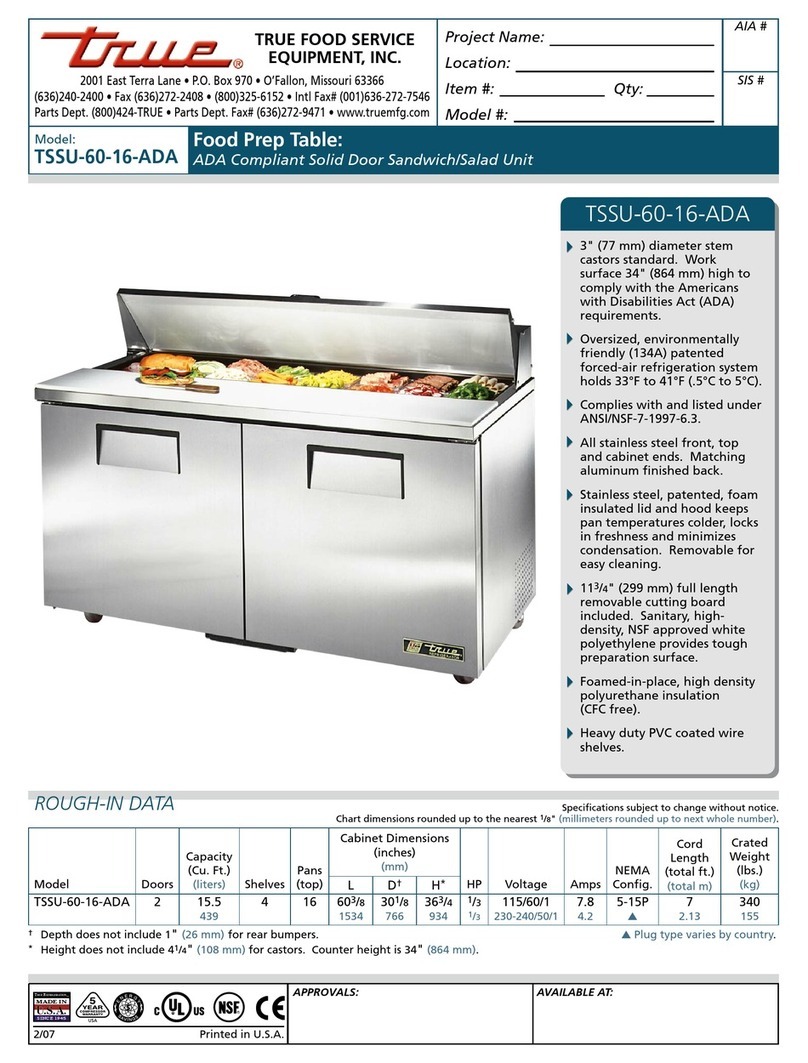

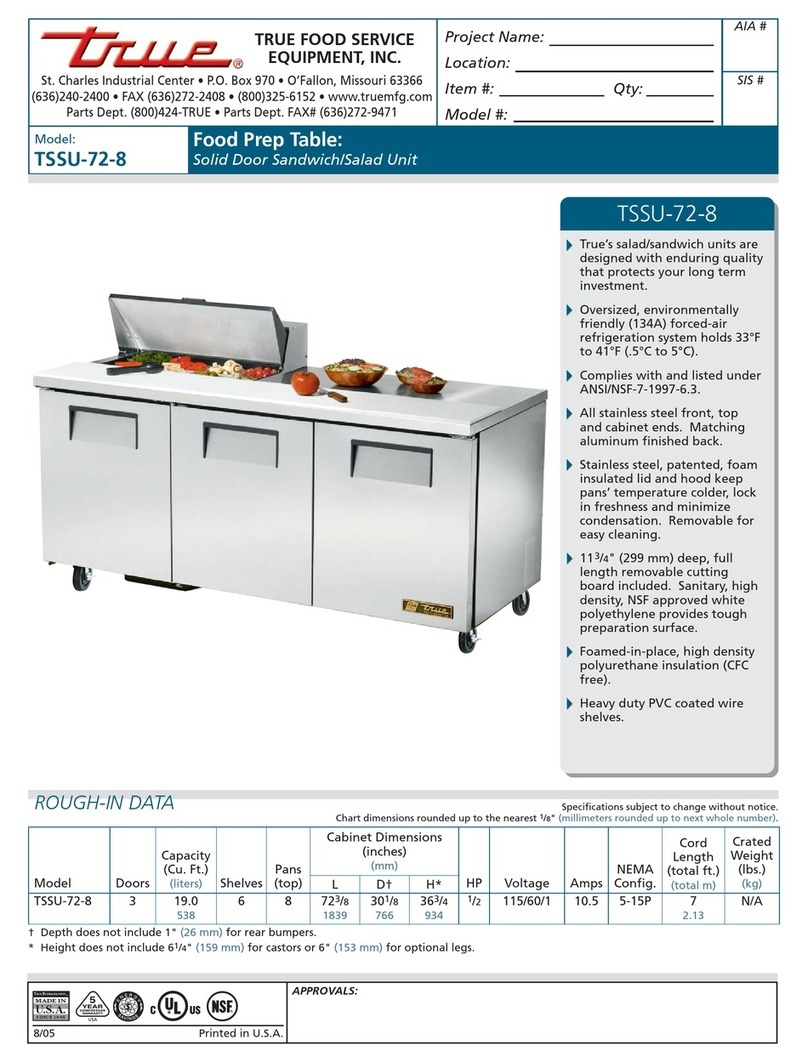

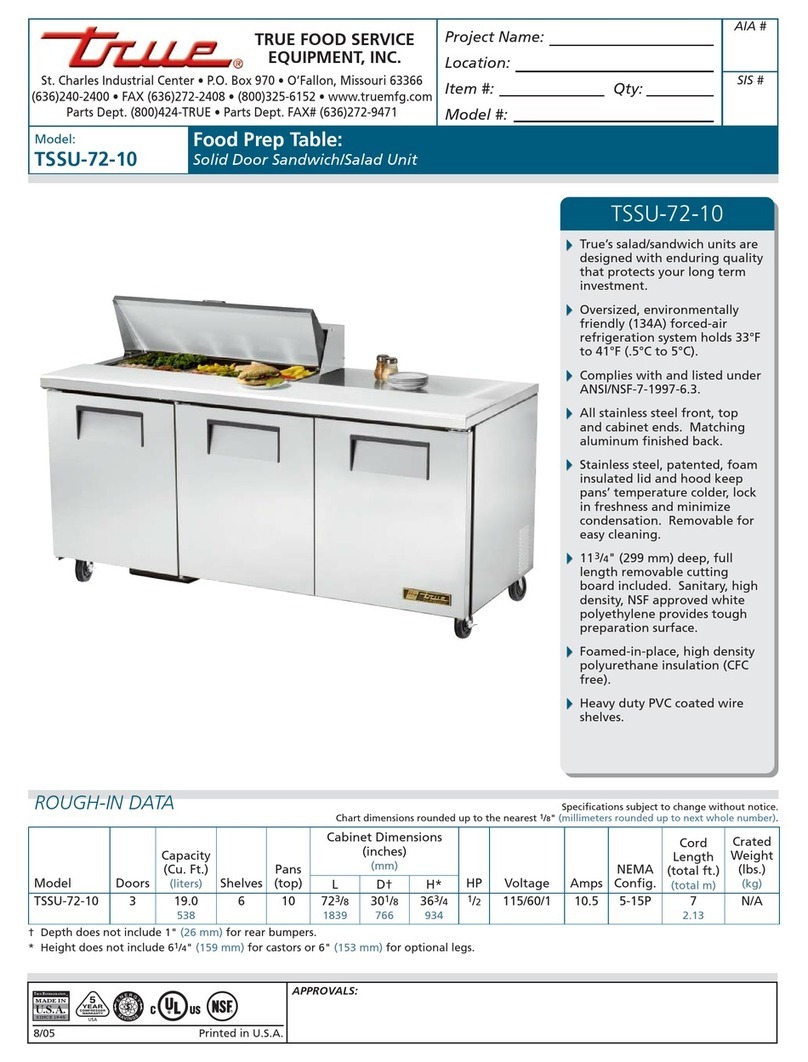

STANDARD FEATURES

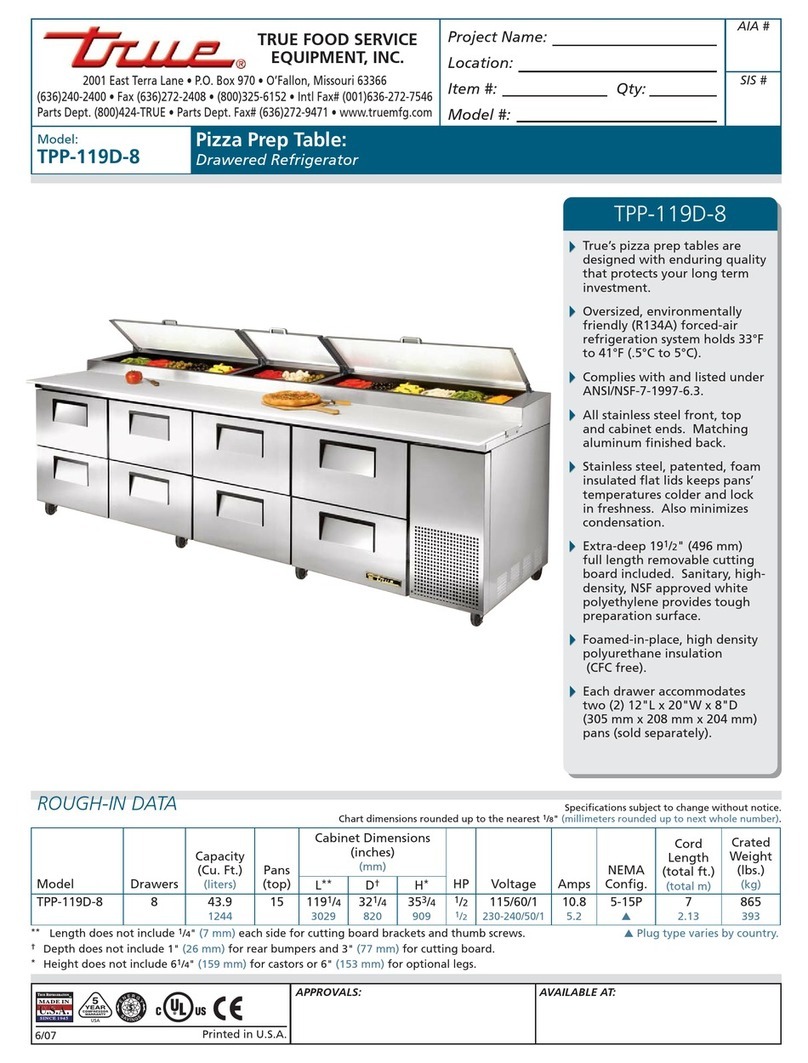

Model:

TRUE FOOD SERVICE EQUIPMENT

2001 East Terra Lane • P.O. Box 970 • O’Fallon, Missouri 63366 • (636)240-2400 • Fax (636)272-2408 • (800)325-6152 • Intl. Fax# (001)636-272-7546 • www.truemfg.com

WARRANTY

One year warranty on all parts

and labor and an additional 4

year warranty on compressor.

(U.S.A. only)

METRIC DIMENSIONS ROUNDED UP TO THE

NEAREST WHOLE MILLIMETER

SPECIFICATIONS SUBJECT TO CHANGE

WITHOUT NOTICE

Model Elevation Right Plan 3D

PLAN VIEW

KCL

DESIGN

• True’s commitment to using the

highest quality materials and oversized

refrigeration systems provides the user

with colder product temperatures, lower

utility costs, exceptional food safety and

the best value in today’s food service

marketplace.

REFRIGERATION SYSTEM

• Factory engineered, self-contained

capillary tube system using

environmentally friendly (CFC free)

R134A refrigerant.

• Oversized, factory balanced refrigeration

system with guided airflow to provide

uniform temperature in food pan rail and

cabinet interior.

• Forced-air design holds 33°F to 41°F

(.5°C to 5°C) product temperature in food

pans and cabinet interior. Complies with

and listed under ANSI/NSF-7-1997-6.3.

• Condensing unit accessed from front

behind removable panel on right hand

side of cabinet, slides out for easy

maintenance.

CABINET CONSTRUCTION

• Exterior - stainless steel front, top and

cabinet ends. Matching aluminum

finished back.

• Interior - attractive, NSF approved, white

aluminum liner. 300 series stainless floor

with coved corners.

• Insulation - entire cabinet structure and

drawer facings are foamed-in-place using

high density, CFC free, polyurethane

insulation.

• 5" (127 mm) diameter stem castors. 36"

(915 mm) work surface height.

DRAWERS

• Stainless steel exterior with white

aluminum liner to match cabinet interior.

• Each drawer fitted with 12" (305 mm)

long recessed handle that is foamed-

in-place with a sheet metal interlock to

ensure permanent attachment.

• Magnetic drawer gaskets of one piece

construction, removable without tools for

ease of cleaning

• Heavy-duty stainless steel drawer slides

and rollers. Removable without tools for

easy cleaning.

PAN CAPACITY

• Each drawer accommodates two (2)

full size 12"L x 20"W x 8"D (305 mm

x 508 mm x 204 mm) food pans (sold

separately). Drawer will support varying

pan configurations with pan dividers bars

(drawer pans and divider bars optional).

MODEL FEATURES

• Evaporator is epoxy coated to eliminate

the potential of corrosion.

• Extra-deep 191/2" (496 mm) full length

removable cutting board included.

Sanitary, high-density, NSF approved

white polyethylene provides tough

preparation surface.

• Stainless steel, patented, foam insulated

flat lid keeps pans’ temperature colder,

locks in freshness, and minimizes

condensation.

• Refrigerated pan rail comes standard with

six (1/3size) 123/4"L x 61/4"W x 6"D

(324 mm x 159 mm x 153 mm) NSF

approved clear polycarbonate insert pans.

• NSF-7 compliant for open food product.

ELECTRICAL

• Unit completely pre-wired at factory and

ready for final connection to a 115/60/1

phase - 15 amp dedicated outlet. Cord

and plug set included.

OPTIONAL FEATURES/ACCESSORIES

Upcharge and lead times may apply.

❒ 230 - 240V / 50 Hz.

❒6" (153 mm) standard legs.

❒6" (153 mm) seismic/flanged legs.

❒3" (85 mm) diameter castors.

❒ Garnish rack.

❒ Pizza prep service shelf.

❒ Single utility shelf.

❒ Double utility shelf.

❒ 191/2" (496 mm) deep, 1/2" (13 mm) thick,

white polyethylene cutting board.

❒ 191/2" (496 mm) deep, 1/2" (13 mm) thick,

composite cutting board.

❒ Pan dividers.

❒ Exterior round digital thermometer

(factory installed).

❒ Remote cabinets (condensing units

supplied by others; system comes

standard with 404A expansion valve and

requires R404A refrigerant). Consult

factory technical service department for

BTU information.

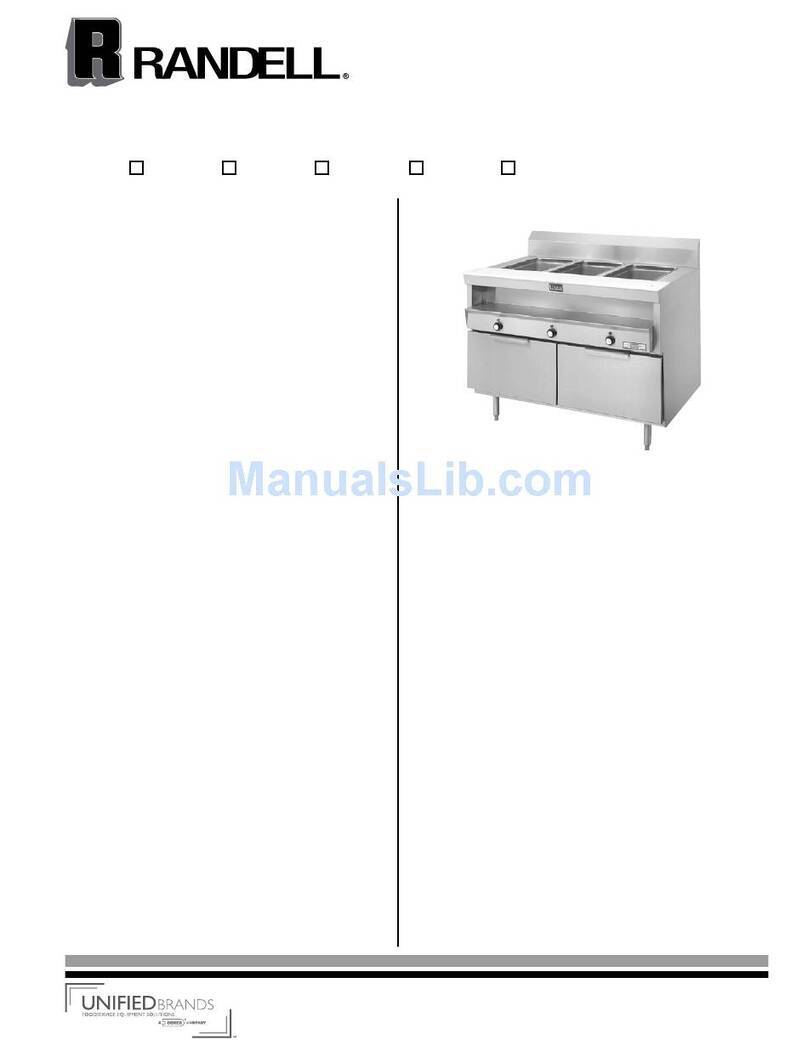

TPP-44D-2 TFQY70E TFQY43S TFQY70P TFQY703

TPP-44D-2

115/60/1

NEMA-5-15R

Pizza Prep Table:

Drawered Refrigerator

123/4"

(324 mm)

81/4"

(210 mm)

ELEVATION PLAN VIEW

441/2"

(1131 mm)

417/8"

(1064 mm)

281/4"

(718 mm)

293/4"

(756 mm)

1/4"

(7 mm)

each side for

cutting board

brackets and

thumb screws

1/4"

(7 mm)

25/8"

(67 mm)

RIGHT VIEW

4911/16"

(1263 mm)

417/8"

(1064 mm)

321/4"

(820 mm)

355/32"

(893 mm)

1"

(26 mm)

587/8"

(1496 mm)

3511/16"

(907 mm)

255/8"

(651 mm)

39/16"

(91 mm)

133/4"

(350 mm)

63/16"

(158 mm)

5"

(127 mm)