11

True Food Service Equipment, Inc.

............ www.truemfg.com ............

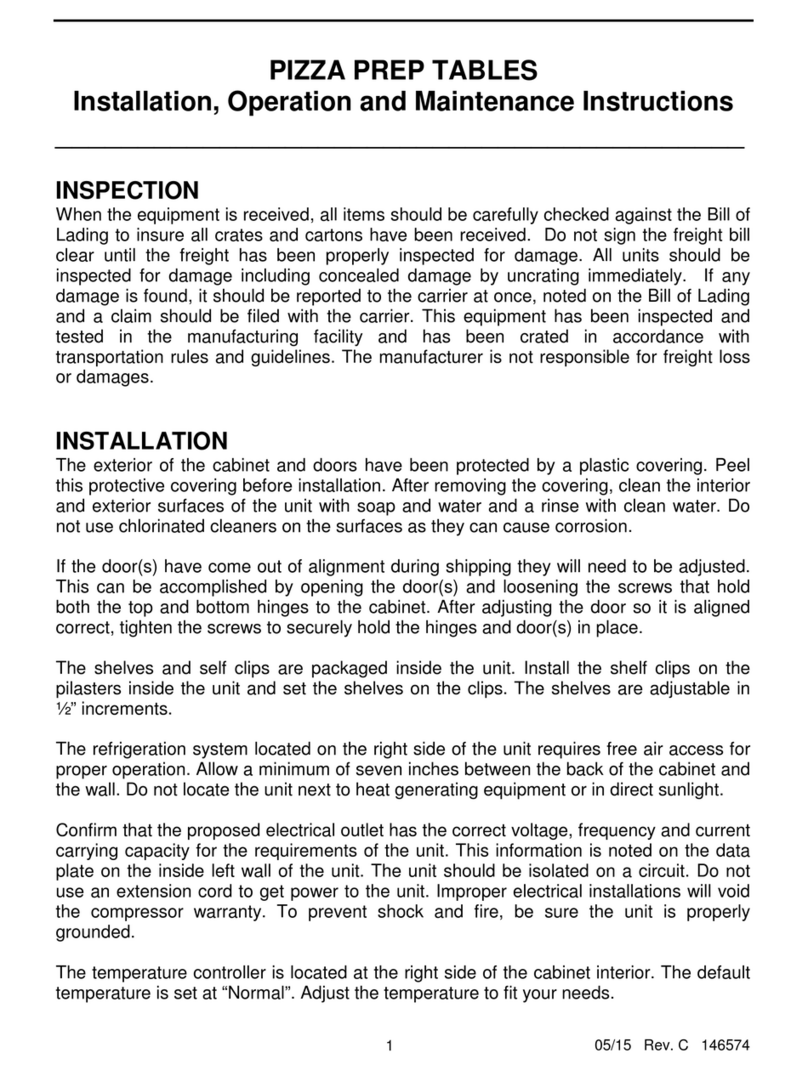

SAFETY INFORMATION

• Thisrefrigeratormustbeproperlyinstalled

andlocatedinaccordancewiththeInstallation

Instructionsbeforeitisused.

• Donotallowchildrentoclimb,standorhangonthe

shelvesintherefrigerator.Theycoulddamagethe

refrigeratorandseriouslyinjurethemselves.

• Donottouchthecoldsurfacesintherefrigerator

compartmentwhenhandsaredamporwet.Skin

maysticktotheseextremelycoldsurfaces.

• Donotstoreorusegasolineorotherflammable

vaporsandliquidsinthevicinityofthisoranyother

appliance.

• Keepfingersoutofthe“pinchpoint”areas;

clearancesbetweenthedoorsandbetweenthedoors

andcabinetarenecessarilysmall;becarefulclosing

doorswhenchildrenareinthearea.

NOTE

We strongly recommend that any servicing be preformed by

a qualified individual.

• Unplugtherefrigeratorbeforecleaningand

makingrepairs.

• Settingtemperaturecontrolstothe0positiondoes

notremovepower.

• Danger-Riskoffireorexplosion.Flammablerefrigerantused.Donotusemechanicaldevicestodefrost

refrigerator.Donotpuncturerefrigeranttubing.

• Danger-Riskoffireorexplosion.Flammablerefrigerantused.Toberepairedonlybytrainedservicepersonnel.

Donotpuncturerefrigeranttubing.

• Caution-Riskoffireorexplosion.Flammablerefrigerantused.Consultrepairmanual/owner’sguidebefore

attemptingtoservicethisproduct.Allsafetyprecautionsmustbefollowed.

• Caution-Riskoffireorexplosion.Disposeofproperlyinaccordancewithfederalorlocalregulations.Flammable

refrigerantused.

• Caution-Riskoffireorexplosionduetopunctureofrefrigeranttubing;followhandlinginstructionscarefully.

Flammablerefrigerantused.

• Caution-Keepclearofobstructionallventilationopeningsintheapplianceenclosureorinthestructurefor

building-in.

WARNING!

Use this appliance for its intended purpose as described in this Owner Manual.

TO LOCATE REFRIGERANT TYPE, SEE SERIAL LABEL INSIDE CABINET.

This cabinet may contain fluorinated greenhouse gas covered by the Kyoto Protocol (please refer

to cabinet’s inner label for type and volume, GWP of 134a= 1,300. R404a= 3,800).

For Hydrocarbon Refrigeration Only (R-290) See Below:

How to Maintain Your TRUE Unit to Receive the Most Efficient and

Successful Operation

You have selected one of the finest commercial refrigeration units made. It is manufactured under strict quality controls with

only the best quality materials available. Your TRUE cooler when properly maintained will give you many years of trouble-

free service.

SAFETY PRECAUTIONS

When using electrical appliances, basic safety precautions should be followed, including the following: