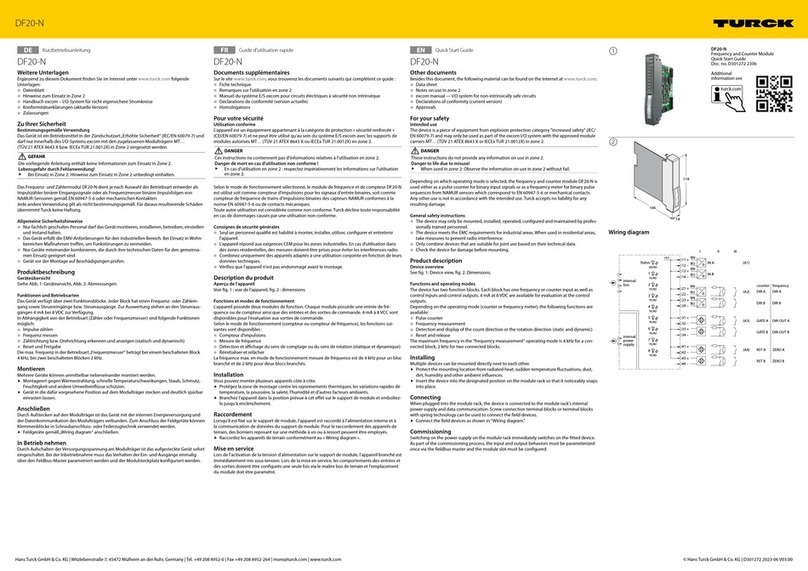

Flow monitoring

For the connection of intrinsically safe flow sensors

IO-Link device with relay outputs

FMX-IM-3UR38X

Edition • 2018-04-09T15:50:43+02:00

4 / 4 TURCK Inc. ñ 3000 Campus Drive Minneapolis, MN 55441-2656 ñ Phone: 763-553-7300 ñ Application Support: 1-800-544-7769 ñ Fax 763-553-0708 ñ www.turck.com

Operating manual

Intended use

This device fulfills the directive 2014/34/EC and can be applied in explosion hazardous areas according to EN60079-0, EN60079-11 and

EN61241-11 as associated equipment for connection to intrinsically safe flow sensors.

In order to ensure correct operation to the intended purpose it is required to observe the national regulations and directives.

For use in explosion hazardous areas conform to classification

II (1) G and II (1) D (Group II, Category (1) G, electrical equipment for gas-atmospheres and category (1) D, electrical equipment for dust atmo-

spheres)

Marking (see device or technical data sheet)

É II (1) G [Ex ia Ga] IIC T4 acc. to EN60079-11 and EN60079-0/61241-11 and É II (1) D [Ex ia Da] IIIC

Local admissible ambient temperature

-25…+70 °C

Installation/Commissioning

These devices may only be installed, connected and operated by trained and qualified staff. Qualified staff must have knowledge of protection

classes, directives and regulations concerning electrical equipment designed for use in explosion hazardous areas.

Please verify that the classification and the marking on the device comply with the actual application conditions.

This device is accessory equipment which features intrinsically safe circuits as well as non-intrinsically safe circuits. It may only be installed out-

side the explosion hazardous area in dry, clean and well monitored areas. If a declaration of conformity or declaration of the manufacturer as a

category 3 device exists, the device may be installed in zone 2. Special conditions for safe operation must be observed. Intrinsically-safe elec-

trical equipment can be connected to the intrinsically-safe connections. All equipment must comply with the demands for operation in the exist-

ing zone of the explosion hazardous area. If the intrinsically safe circuits lead to the dust explosion hazardous zones 20 or 21, it is important to

ensure that the devices connected to this circuit fulfil the demands for category 1D or 2D and are certified accordingly. If the equipment is inter-

connected, it is necessary to perform the "Proof of intrinsic safety" (EN 60079-14). Equipment which has been used once to connect intrinsical-

ly safe circuits to non-intrinsically safe circuits is no longer suitable for subsequent use with intrinsically safe circuits. Relevant regulations ex-

ist for the establishment of intrinsically-safe circuits, mounting of external connection parts as well as the characteristics and laying of cables.

Cables and terminals with intrinsically-safe circuits must be marked. They should be separated from non-intrinsically safe circuits or must fea-

ture appropriate insulation (EN 60079-14). Observe the prescribed clearances to earthed components and connections of other devices to the

intrinsically-safe connections of this device. Unless expressed specifically in the device-specific operating instructions, the approval becomes

void if the device is opened, repaired or actions are performed on the device by someone other than approved experts or the manufacturer. Vis-

ible changes to the device housing, such as brown-black discolourations caused by heat, as well as holes or bulges also indicate a serious dan-

ger. Switch off the device immediately. With the associated electrical equipment the interconnected intrinsically-safe equipment must also be

checked. Inspection of a device with regard to the explosion protection can only be performed by an expert or the manufacturer. The operation

of the devices is only permitted in conjunction with the permitted data printed on the side of the housing. Before any commissioning or modifica-

tion of the device interconnections, ensure that the respective regulations, directives and conditions have been complied with and also ensure

that use is only for the intended purpose and the safety requirements have been fulfilled.

After connection to other circuits the sensor may no longer be used in Exi installations. When interconnected to (associated) electrical equip-

ment, it is required to perform the "Proof of intrinsic safety" (EN60079-14).

Installation and mounting instructions

Avoid static charging of cables and plastic devices. Please only clean the device with a damp cloth. Do not install the device in a dust flow and

avoid build-up of dust deposits on the device.

If the devices and the cable could be subject to mechanical damage, they must be protected accordingly. They must also be shielded against

strong electro-magnetic fields.

The pin configuration and the electrical specifications can be taken from the device marking or the technical data sheet.

In order to avoid contamination of the device, please remove possible blanking plugs of the cable glands or connectors only shortly before in-

serting the cable or opening the cable socket.

Special conditions for safe operation

The device must be protected against any kind of mechanical damage.

Service/Maintenance

Repairs are not possible. The approval expires if the device is repaired or modified by a person other than the manufacturer. The most important

data from the approval are listed.