Turner Designs TD-4100XD E09 Installation and operating instructions

Other Turner Designs Measuring Instrument manuals

Turner Designs

Turner Designs Ballast-Check 2 User manual

Turner Designs

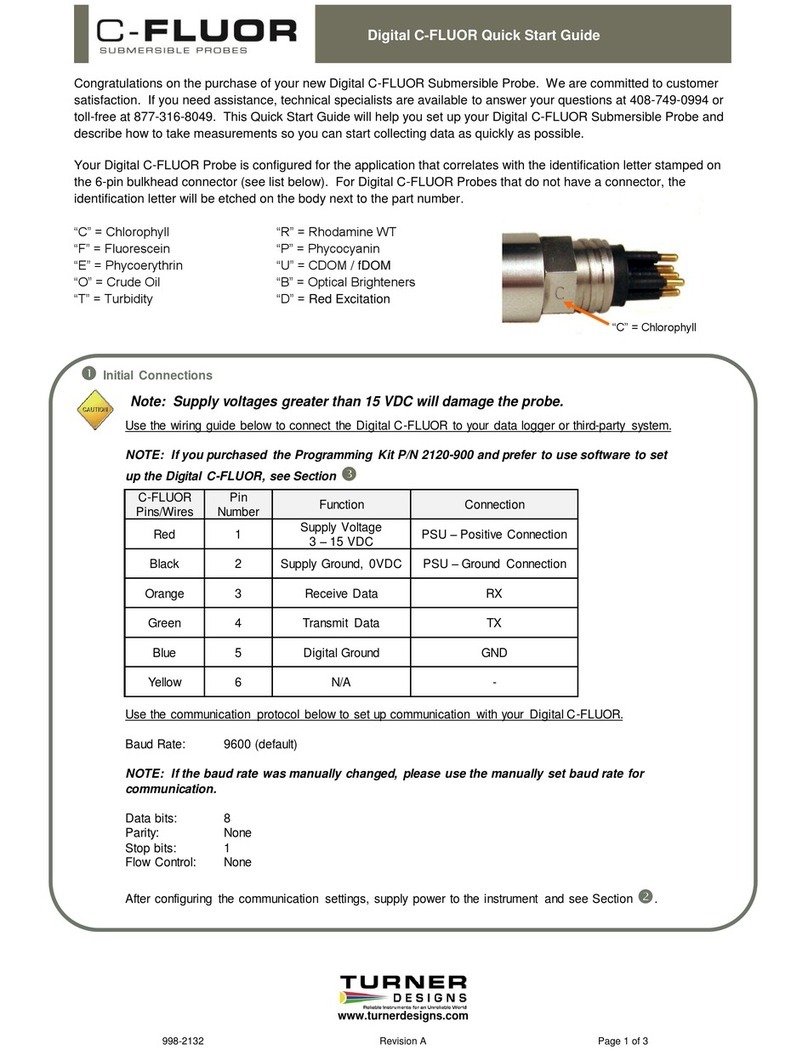

Turner Designs C-FLUOR User manual

Turner Designs

Turner Designs C-FLUOR User manual

Turner Designs

Turner Designs AquaFlash User manual

Turner Designs

Turner Designs 10-AU Use and care manual

Turner Designs

Turner Designs TD-5100 ECA User manual

Turner Designs

Turner Designs TD-107 5.0 User manual

Turner Designs

Turner Designs 8000 Manual

Turner Designs

Turner Designs C3 User manual

Turner Designs

Turner Designs Enviro-T User manual

Turner Designs

Turner Designs Little Dipper User manual

Turner Designs

Turner Designs AquaFlash User manual

Turner Designs

Turner Designs 10-AU Guide

Turner Designs

Turner Designs Ballast-Check 2 User manual

Turner Designs

Turner Designs TD-20/20 User manual

Turner Designs

Turner Designs Ballast-Check 2 User manual

Turner Designs

Turner Designs FluoroSense User manual

Turner Designs

Turner Designs C3 User manual

Turner Designs

Turner Designs Ballast-Check 2 User manual

Turner Designs

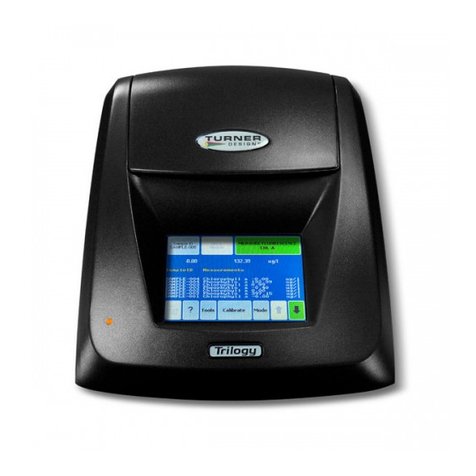

Turner Designs Trilogy User manual