408- 4321

Pneumatic CERTI- CRIMP Tool Holder 356304- 1

3of 4Rev CTyco Electronics Corporation

4. Slowly crimp the contact onto the wire until the

crimping dies bottom on the shim. Check that the

ratchet releases after the dies bottom.

Before adjusting the ratchet pawl position,

DISCONNECT THE TOOL FROM THE AIR

SUPPLY. After the adjustment, ALWAYS ensure

that the tool holder pivot pins are fully tightened

to avoid personal injury or damage to the tool.

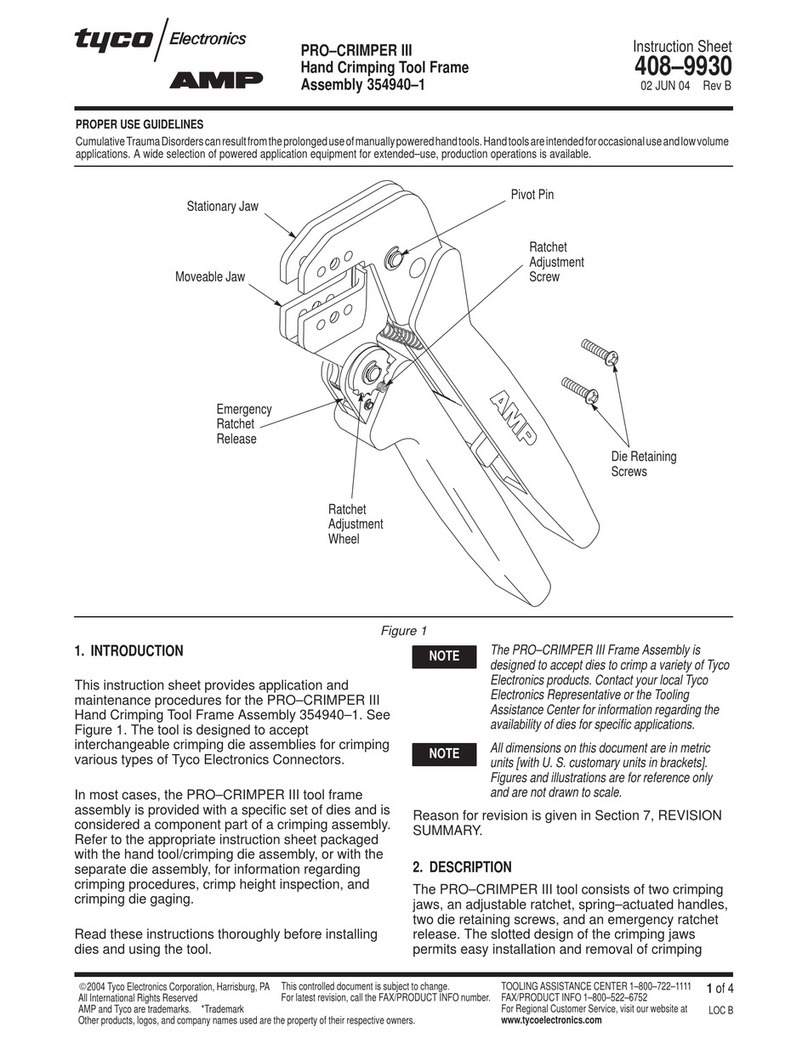

5. If the ratchet releases before the dies bottom,

loosen the three securing screws, remove the

eccentric adjustment screw (refer to Figure 1) and

rotate the eccentric clockwise to a higher setting.

Tighten the securing screws. Repeat as required.

If the ratchet does not release and the tool will

not return, slowly actuate the tool until the force

of the cam teeth is off the pawl, then push on the

pawl with a small screwdriver until the pawl is

released from the teeth, release the tool switch

and allow the tool to return. See Figure 3.

Figure 3

Ratchet Pawl with

Emergency Release

Press Pawl with

Screwdriver

6. If the ratchet does not release after the crimping

dies bottom, loosen the three securing screws,

remove the eccentric adjustment screw and rotate

the eccentric counterclockwise to a lower setting.

Tighten the securing screws. Repeat as required.

7. If the crimp cannot be made to conform to the

dimensions provided in the appropriate application

specification, the crimp head adapter and/or

crimping dies are defective and must be replaced.

5. MAINTENANCE AND INSPECTION

To avoid injury, DISCONNECT TOOL FROM AIR

SUPPLY before performing any maintenance or

inspection procedures.

Tyco Electronics recommends that a maintenance

and inspection program be performed periodically to

ensure dependable and uniform terminations. The

tool holder should be inspected once a week.

Frequency of inspection should be adjusted to suit

your requirements through experience, and depends

on:

SCare, amount of use, and handling of tool

holder

SType and size of the products crimped

SDegree of operator skill

SPresence of abnormal amounts of dust and dirt

SYour own established standards.

The tool holder is thoroughly inspected before

packaging. Since there is the possibility of damage

during shipment, the tool holder should be inspected

immediately upon arrival at your facility.

5.1. Maintenance

A. Cleaning

Remove dust, moisture, and other contaminants with

a clean, soft brush, or a soft, lint--free cloth. Do NOT

use objects that could damage the tool. Lubricate tool

holder as instructed in Paragraph 5.1,B, Lubrication,

before placing the it back into service.

B. Lubrication

Lubricate all pins, pivot points, and bearing surfaces

with a high quality grease. Tyco Electronics

recommends the use of MolykoteHgrease, which is a

commercially available lubricant. Lubricate according

to the following schedule:

Holder used in daily production—lubricate daily

Holder used daily (occasional)—lubricate weekly

Holder used weekly—lubricate monthly

Wipe excess grease from tool holder, particularly from

die closure areas. Grease transferred from the die

closure area onto certain terminations may affect the

electrical characteristics of an application.

5.2. Periodic Inspection

Regular inspections of the tool holder should be

performed by quality control personnel. A record of

scheduled inspections should remain with the tool

holder or be supplied to supervisory personnel

responsible for the tool holder. Inspection frequency

should be based upon amount of use, working

conditions, operator training and skill, and established

company standards.

1. Inspect the tool holder for missing pins or parts.

If parts are missing or defective, replace them by

referring to Figure 4.

2. Check all bearing surfaces for wear. Replace

any worn parts.

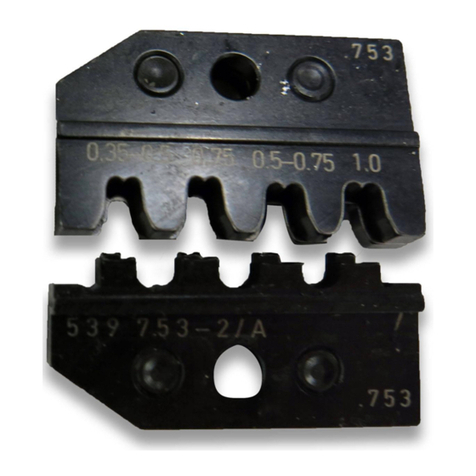

3. Inspect crimping dies for flattened, chipped, or

broken areas. Worn or damaged surfaces are

objectionable and will affect the quality of the

crimp.

HTrademark of Dow Corning Corporation

DANGER

NOTE

i

DANGER