408–9930

PRO–CRIMPER III Hand Crimping Tool Frame Assembly354940–1

3of 4Rev B

4. MAINTENANCE/INSPECTION

4.1. Daily Maintenance

Tyco Electronics recommends that operators of the

tool be made aware of, and responsible for, the

following steps of daily maintenance:

1. Remove dust, moisture, and any other

contaminants from the tool with a clean, soft brush,

or a clean, soft, lint–free cloth. Do NOT use hard or

abrasive objects that could damage the tool.

2. Make certain that the pivot pins are in place and

that they are secured with retaining rings.

3. All pins, pivot points, and bearing surfaces

should be protected with a thin coat of any good

SAE No. 20 motor oil. Do not oil excessively.

4. When the tool is not in use, keep handles closed

to prevent objects from becoming lodged in the

crimping jaws. Store the tool in a clean, dry area.

4.2. Periodic Inspection

Regular inspections of the tool should be performed

by quality control personnel. A record of scheduled

inspections should remain with the tool or be supplied

to supervisory personnel responsible for the tool.

Inspection frequency should be based upon amount

of use, working conditions, operator training and skill,

and established company standards.

1. Remove all lubrication and accumulated film by

immersing the tool (handles partially closed) in a

suitable commercial degreaser that will not affect

paint or plastic material.

2. Make certain that all pivot pins are in place and

secured with retaining rings.

3. Close tool handles until ratchet releases and

then allow them to open freely. If they do not open

quickly and fully, the spring is defective and must

be replaced. See Paragraph 6, PARTS

REPLACEMENT.

4. Inspect the tool frame for wear or damage,

paying particular attention to the tool jaws and

pivot points. If damage is evident, refer to

Paragraph 6, PARTS REPLACEMENT. If tool is

acceptable, lubricate and return to service.

This tool is recommended for R&D prototyping,

networkingapplications,commercial/industrial

maintenance, and field service repair. For other

applications, please contact your Tyco Electronics

Sales Representative or the Customer Tooling

AssistanceCenterat 1–800–722–1111.

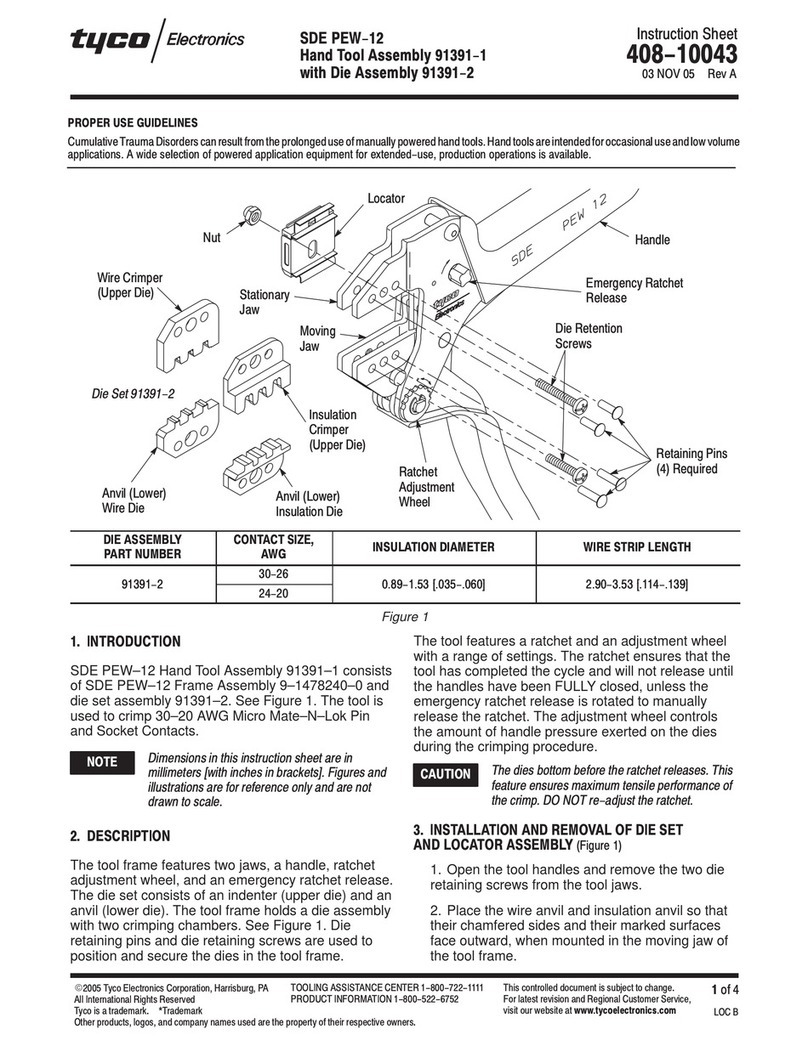

5. CRIMP HEIGHT ADJUSTMENT

The tool frame assembly features a ratchet

mechanism and adjustment wheel with a range of

settings. The ratchet mechanism ensures that the tool

has completed the cycle. The adjustment wheel

controls the amount of handle pressure exerted on

the tool jaws and crimping dies during the crimping

procedure. Although the ratchet is preset prior to

shipment, it is important that you verify the crimp

height. Also, general use and subsequent wear may

cause the tool to go out of adjustment. It is

recommended that the crimp height be inspected —

and adjusted, if necessary — on a regular basis by

quality control personnel.

This is a general explanation of the procedure.

For specific information, refer to the instruction

sheet packaged with the die assembly.

1. Crimp a contact onto a properly–prepared wire

of the correct size.

2. If the crimp height is greater than

recommended, remove the ratchet wheel

adjustment screw and rotate the adjustment wheel

COUNTERCLOCKWISE to a higher setting.

Repeat as required.

3. If the crimp height is less than recommended,

remove the ratchet wheel adjustment screw and

rotate the adjustment wheel CLOCKWISE to a

lower setting. Repeat as required.

4. If the crimp cannot be made to conform to the

dimensions provided in the appropriate product

application specification, the tool and/or dies are

defective and must be replaced.

6. PARTS REPLACEMENT

PRO–CRIMPER III Hand Crimping Tool Frame

Assembly 354940–1 is inspected prior to shipment. It

is recommended that it be inspected upon arrival to

ensure that it has not become damaged during

shipping.

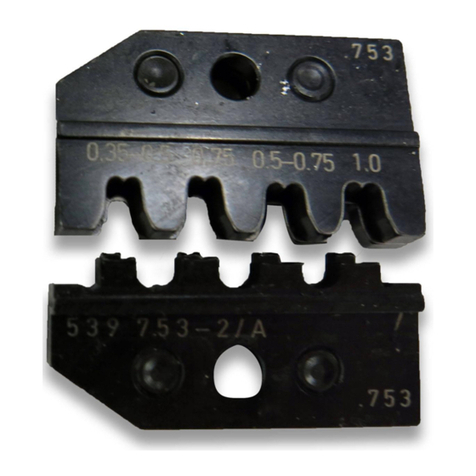

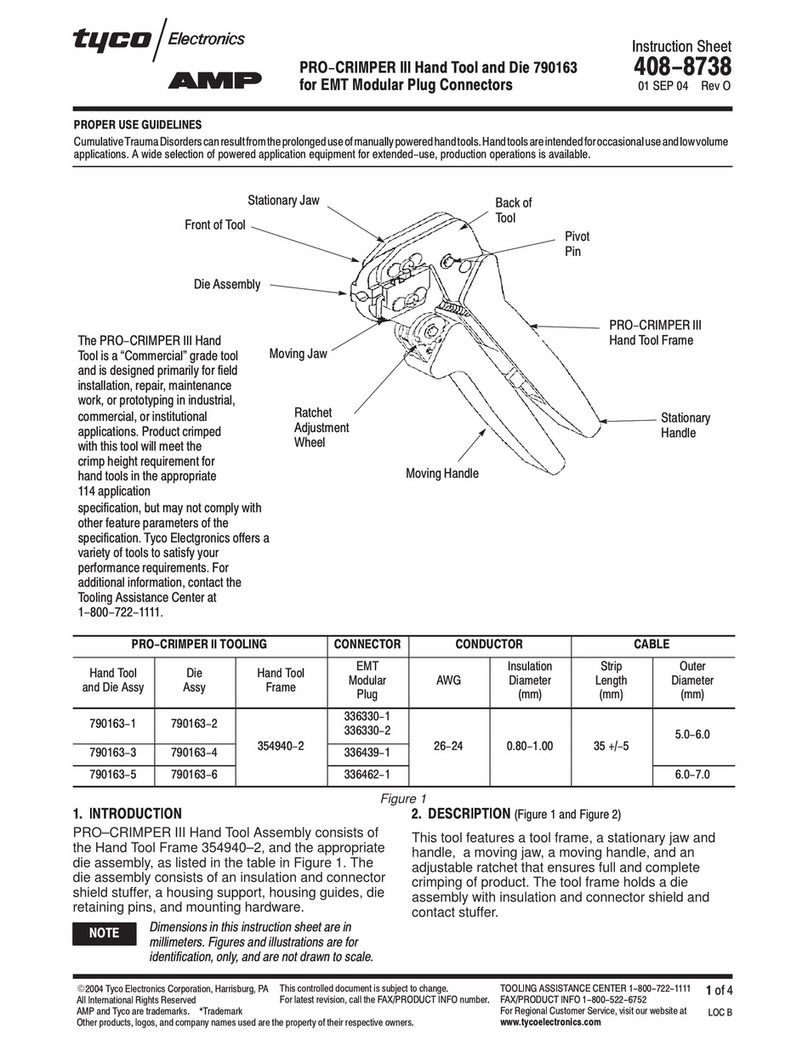

Refer to the parts list in Figure 4 to determine the part

number for the item to be replaced and to identify the

proper location and orientation of the part in the tool

frame.

Additional tools and parts may be ordered from:

CUSTOMER SERVICE (38–35)

TYCO ELECTRONICS CORPORATION

P.O. BOX 3608

HARRISBURG, PA 17105–3608

7. REVISION SUMMARY

Per EC 0990–0647–04:

S

Updated document to corporate requirements

S

Changed PRO–CRIMPER “II” to “III” in all

instances

NOTE

NOTE