409-5128-3

AMP-O-LECTRIC One-Valve Press 694234-7

Rev

A4

of 9 Tyco Electronics Corporation

When reading this manual, pay particular attention to DANGER, CAUTION, NOTE statements.

Denotes an imminent hazard which ma result in moderate or severe injur .

Denotes a condition which ma result in product or equipment damage.

Highlights special or important information.

Dimensions in this manual are in metric units [with U.S. customar units in brackets].

Reasons for reissue of this document are provided in Section 8, REVISION SUMMARY.

2. DESCRIPTION

2.1. Fun tional Des ription

The following describes the function of the one–valve press beyond the description of the basic press covered

in 409–5128.

In the static condition, the cam switch (S8) is actuated OPEN by the cam on the transmission and the solenoid

valve is de–energized, thus supplying air through the top front port and exhausting return air through the

bottom front port and muffler to the atmosphere.

The press cycle begins the moment the foot switch (S3) is depressed. At approximately 4 degrees of the press

flywheel rotation, the cam switch is de–actuated which CLOSES the circuit to energize the solenoid valve. This

diverts air pressure out of the bottom front port of the solenoid valve and exhaust air back through the top front

port and muffler to the atmosphere. The solenoid valve remains energized as the press ram bottoms and

returns near the top of the upward stroke. At this point, the cam again actuates the cam switch and the circuit

is OPENED to de–energize the solenoid valve as the press returns to the static condition. This completes a

cycle of operation.

The purpose of the motor ON–OFF switch (S4) is to provide a means of stopping the motor for hand–cycling of

the press during setup and adjustments of the special machine or miniature applicator. With this switch OFF

and the main power switch (S2) ON, the solenoid valve is energized and de–energized during hand–cycling of

the press in the same manner as during normal operation.

2.2. Ele tri al Des ription

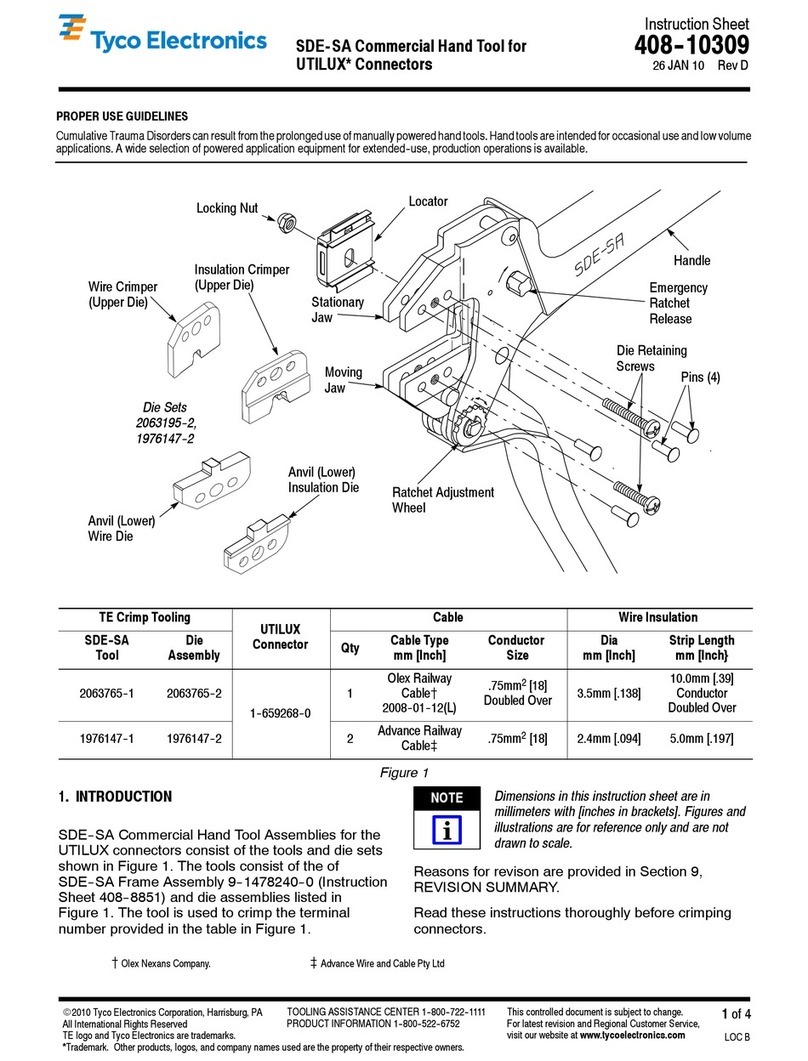

The electrical system is basically the same as the basic machine covered in 409–5128 except with the addition

of the solenoid valve (L2), cam switch (S8), and motor on–off switch (S4) as indicated in Figure 2.

3. RECEIVING INSPECTION AND INSTALLATION

All receiving inspection and installation information contained in 409–5128 is applicable to the one–valve press.

The one–valve press must be installed as described in 409–5128, and the plug must be connected to an

adequate and convenient electrical outlet with 115 Volts, 60 Hz, single phase, and a minimum continuous air

supply of 620 kPa [90 psi] connected to the sleeve valve. The sleeve valve must be OPEN, and the main

power switch (S2) and motor ON–OFF switch (S4) must be ON. With both switches ON, the motor runs

continuously and electric power is supplied to the cam switch (S8).

4. OPERATION

All operating information contained in 409–5128 is applicable to the one–valve press.

DANGER

CAUTION

!

NOTE

i

NOTE

i