Model DSB-2

Dry Sprinkler Boot

For Use With TFP Dry Type Sprinklers

Page 1 of 4 AUGUST 2018 TFP591

IMPORTANT

Refer to Technical Data Sheet

TFP2300 for warnings pertaining to

regulatory and health information.

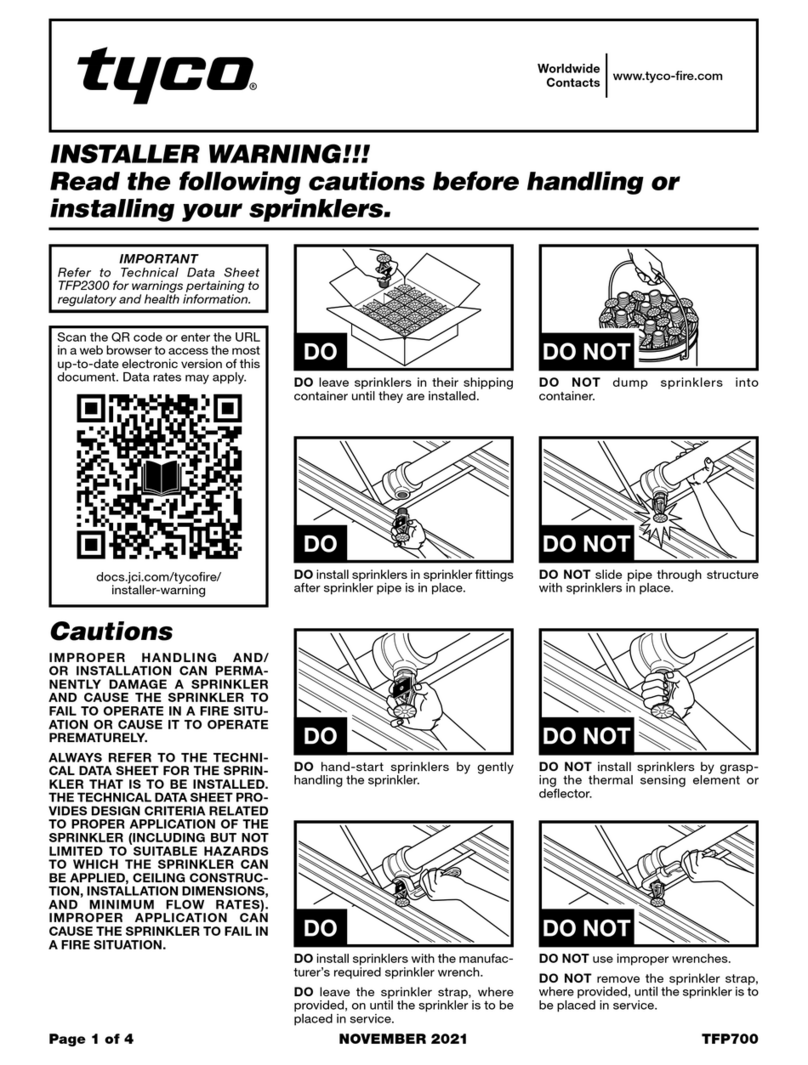

Always refer to Technical Data

Sheet TFP700 for the “INSTALLER

WARNING” that provides cautions

with respect to handling and instal-

lation of sprinkler systems and com-

ponents. Improper handling and

installation can permanently damage

a sprinkler system or its compo-

nents and cause the sprinkler to fail

to operate in a fire situation or cause

it to operate prematurely.

Worldwide

Contacts

www.tyco-fire.com

General

Description

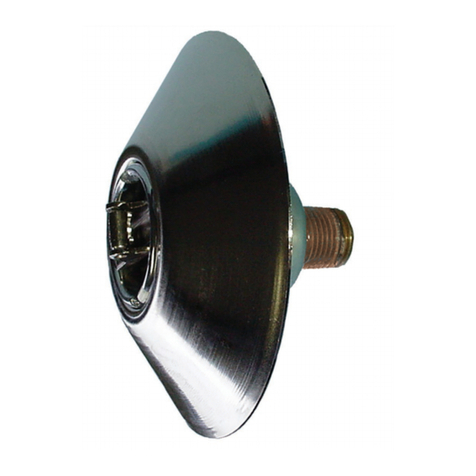

The TYCO Model DSB-2 Dry Sprinkler

Boot (Ref. Figure 1) is designed for use

with TFP Dry Type Sprinklers. When

properly installed, it will help close the

air gap created by the clearance hole

through a wall or ceiling through which

the dry type sprinkler has penetrated.

The DSB-2 is intended predominately

for use with clearance holes through

freezer ceiling structures. In these

types of installations, due to the greater

temperature difference between the

inside and outside of the freezer than

found with other type installations, the

potential for the formation of conden-

sation in the sprinkler and subsequent

ice build-up is increased. If this con-

densation is not controlled, ice build-up

can occur that might damage the dry

type sprinkler and/or prevent proper

operation in a fire situation.

The DSB-2 is intended to help stop the

air exchange between the inside and

outside of the freezer (or any other type

of similar construction) to help prevent

transfer of moist air into the freezer

space. The use of the DSB-2 provides

a quick and efficient means of closing

the air gap created by the dry type

sprinkler clearance hole. The DSB-2

provides the added feature of eliminat-

ing the occurrence of cracking of some

commonly used sealants, that subse-

quently allows the passage of moist air.

NOTICE

The Model DSB-2 Dry Sprinkler Boot

described herein must be installed

and maintained in compliance with

this document, as well as with the

applicable standards of the NATIONAL

FIRE PROTECTION ASSOCIATION, in

addition to the standards of any other

authorities having jurisdiction. Failure

to do so may impair the performance

of these devices.

The owner is responsible for main-

taining their fire protection system

and devices in proper operating con-

dition. Contact the installing contrac-

tor or product manufacturer with any

questions.

Technical

Data

Approvals

The TYCO Model DSB-2 Dry Sprin-

kler Boot does not require laboratory

approval to be installed in accordance

with the applicable standards of the

NATIONAL FIRE PROTECTION ASSO-

CIATION. The use of the DSB-2 does

not alter any of the applicable labo-

ratory approvals for TFP Dry Type

Sprinklers.

The 2007 edition of NFPA 13, Section

8.4.10.2 requires that dry sprinklers

connected to wet pipe sprinkler

systems protecting insulated freezer

structures, the clearance space around

the sprinkler barrel shall be sealed.

Dry Type Sprinkler Compatibility

and Technical Data Sheet

Reference

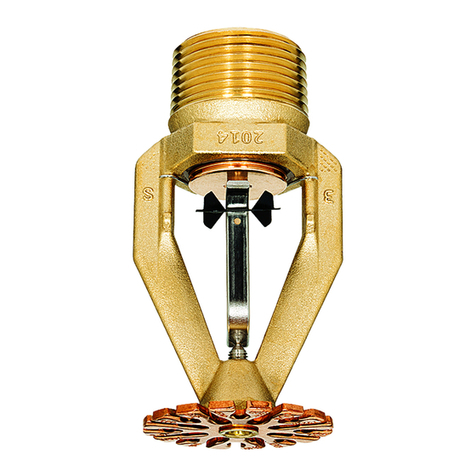

Series DS-1, Standard Response

Standard Coverage,

Pendent, Upright

and HSW . . . . . . . . . . . . . . . . . . . .TFP500

Series DS-1, Quick Response

Standard Coverage,

Pendent, Upright

and HSW . . . . . . . . . . . . . . . . . . . . TFP510

Series DS-C, Standard Coverage

Concealed Pendent ............TFP515

Series DS-ECC, Extended Coverage

Concealed Pendent ............TFP518

Series DS-1, Extended Coverage

Horizontal Sidewall ............TFP520

Series DS-2, Standard

Coverage Pendent .............TFP530

Series DS-2, Extended

Coverage Pendent .............TFP540

Series DS-3, ECOH

Horizontal Sidewall ............TFP550

NOTE: Use of the Model DSB-2 Dry

Sprinkler Boot with non-TFP Dry Type

Sprinklers will void the warranty. Failure

may result due to dimensional differ-

ences in the outside diameter of the

barrel. The DSB-2 has not been tested

with any non-TFP Dry Type Sprinklers

with regard to fit or performance.

Physical Characteristics

The Boot is EPDM, the Strap Ties are

nylon, and the Adhesive is ethyl cyano-

acrylate based. The adhesive is formu-

lated for instant bonding of the Boot to

metal, plastic, or rubber surfaces.

Design

Criteria

There are four items to be considered:

Dry Type Sprinklers, Clearance Hole,

Exposure Length, and Sprinkler Fitting.

Dry Type Sprinklers

This Technical Data section provides

a list of all of the compatible dry type

sprinklers and their associated techni-

cal data sheets. Refer to the applicable

technical data sheet for installation and

maintenance information for the sprin-

kler being utilized.