Page 2 of 3 0714 IH-1250

NOTE: Before operating, check the heater

(heating element), Teflon cover, Teflon

adhesive, and the sealing pad (silicon rubber).

1. Insert the Power Cord into the correct receptacle (110V).

2. Turn the power switch ON.

3. Set the timer knob to lowest setting. Always start with

a low setting and increase gradually. Thicker bags

need a higher setting.

4. Place the end of the bag under the sealing arm

and press the pedal down gently, but firmly. Hold for

2-3 seconds. The red light will go out when sealing

time is complete.

a. If the seal is broken or damaged, decrease the

sealing time.

b. If the seal is not fully welded, increase the

sealing time.

c. If the sealing material sticks to the sealing pad,

decrease the congealing time.

d. If the width of the seal is not perfect or does

not match the size of the element, increase the

congealing time. (Congealing time is necessary

for sealing.)

5. When red light goes out, keep pressing the pedal for

2-3 seconds.

NOTE: Must wait until congealing time is up.

6. Release the Pedal.

ADDITIONAL INFORMATION

1. Always keep the sealer clean. Remove any residue

found on the platform and Teflon cover. Silicon spray

may be used for this purpose.

2. When replacing the heating elements, always check

the condition of the bottom Teflon tape.

3. A worn Teflon Adhesive can cause the heating

element to break. Use only Thermoelectric wire of

the identical specifications.

4. Occasionally check the condition of the silicon

rubber for wear or burns. A damaged silicon rubber

will affect the quality of the seal.

5. Be sure to turn OFF the power or unplug before

replacing any parts.

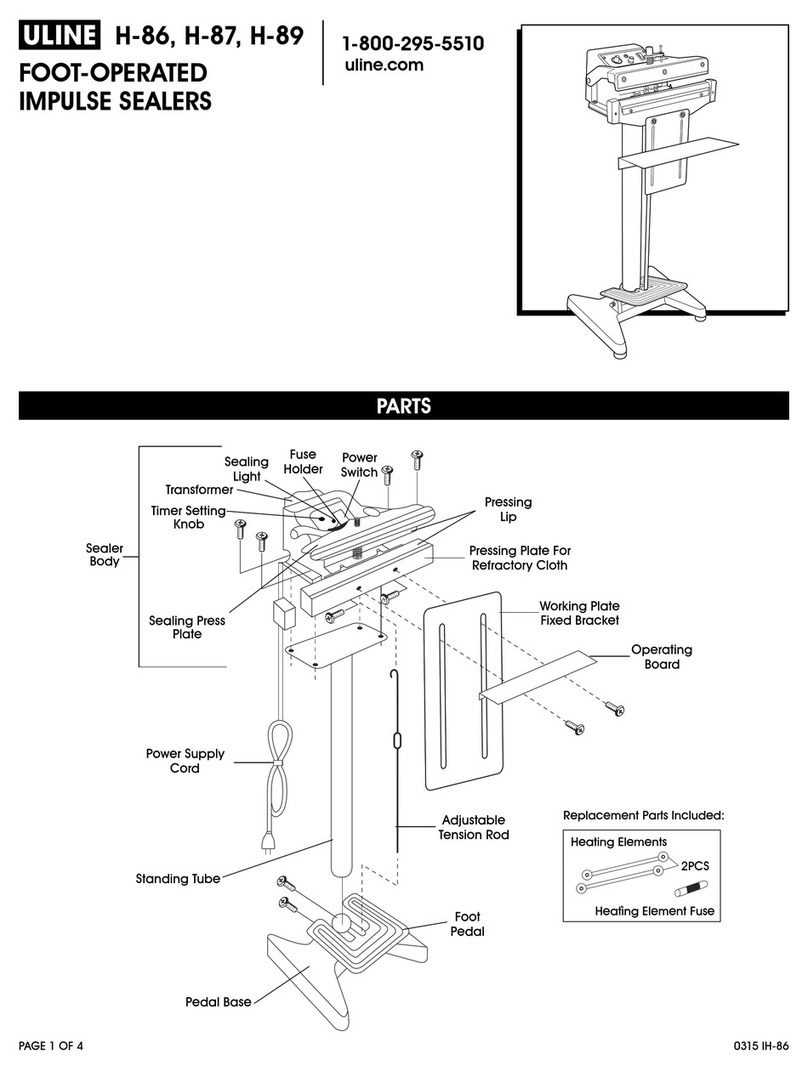

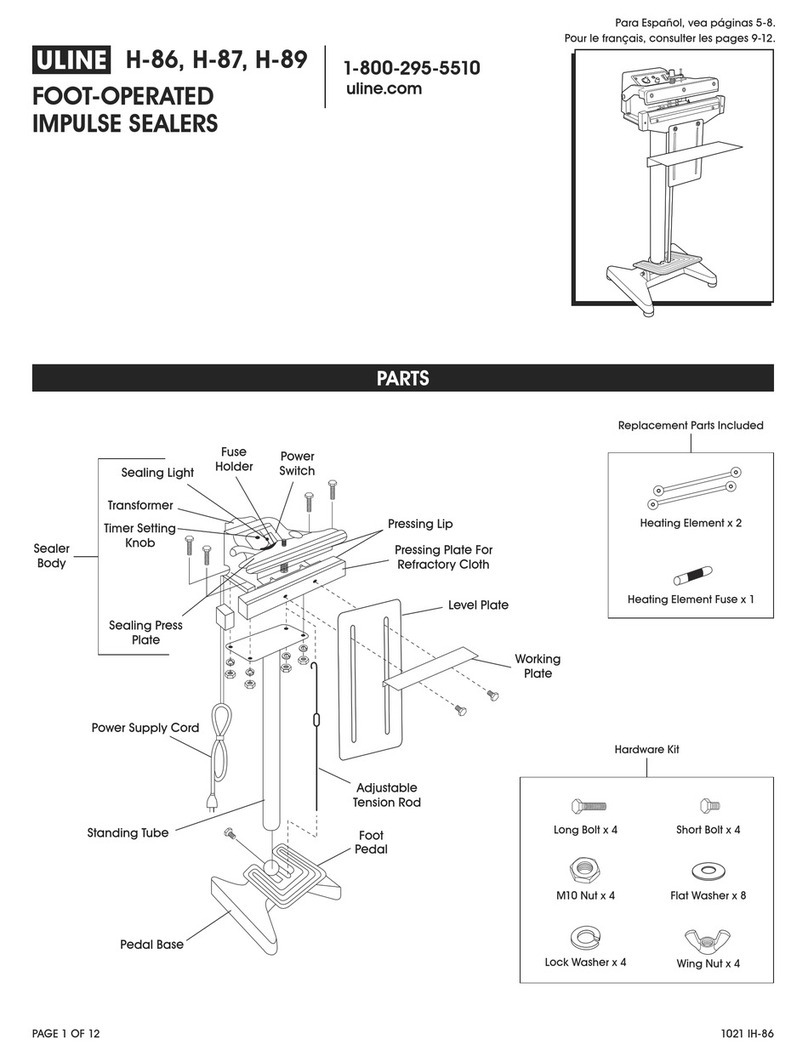

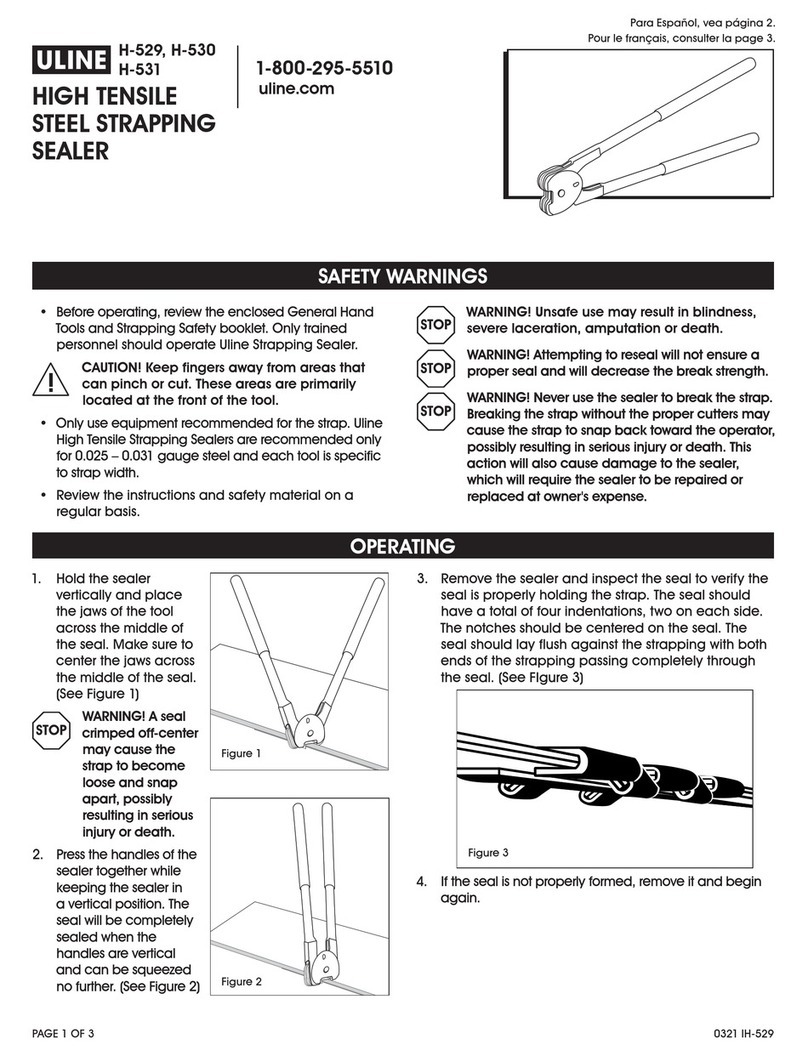

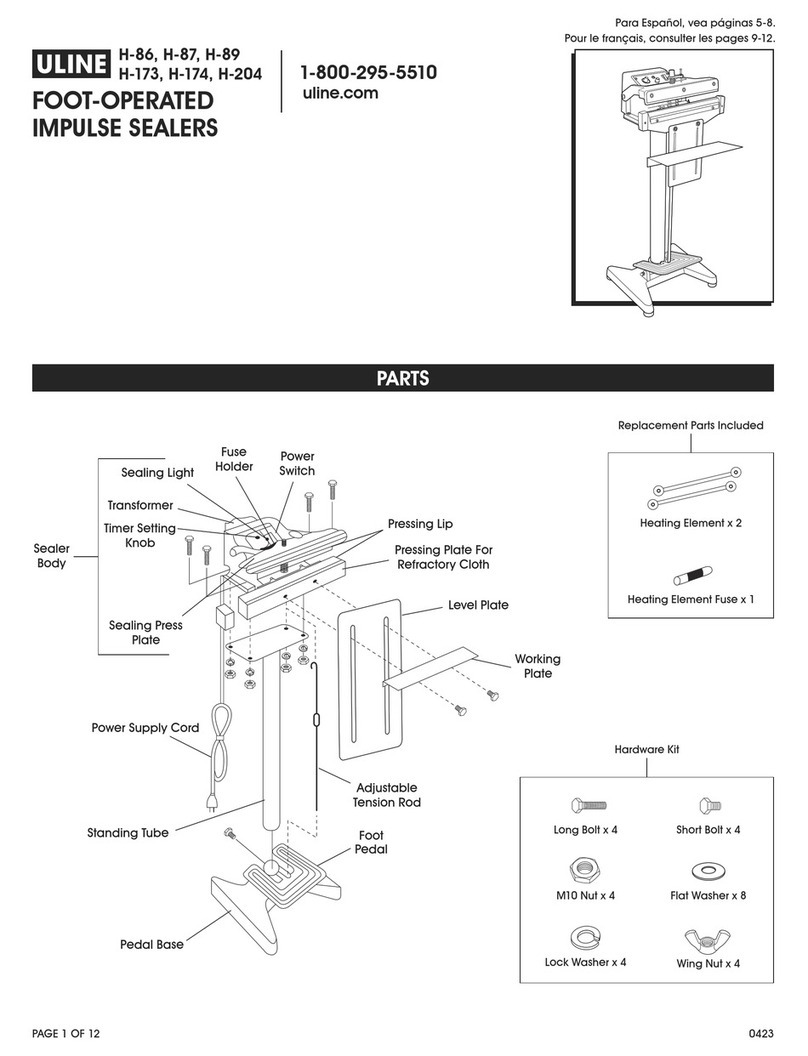

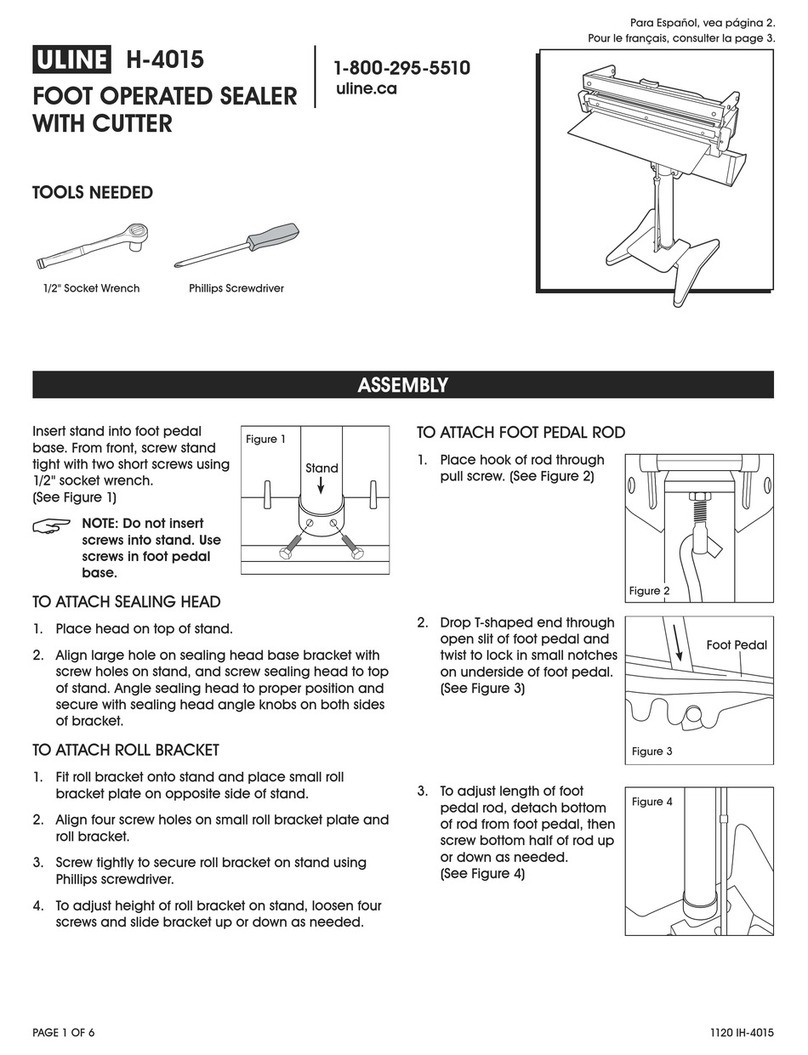

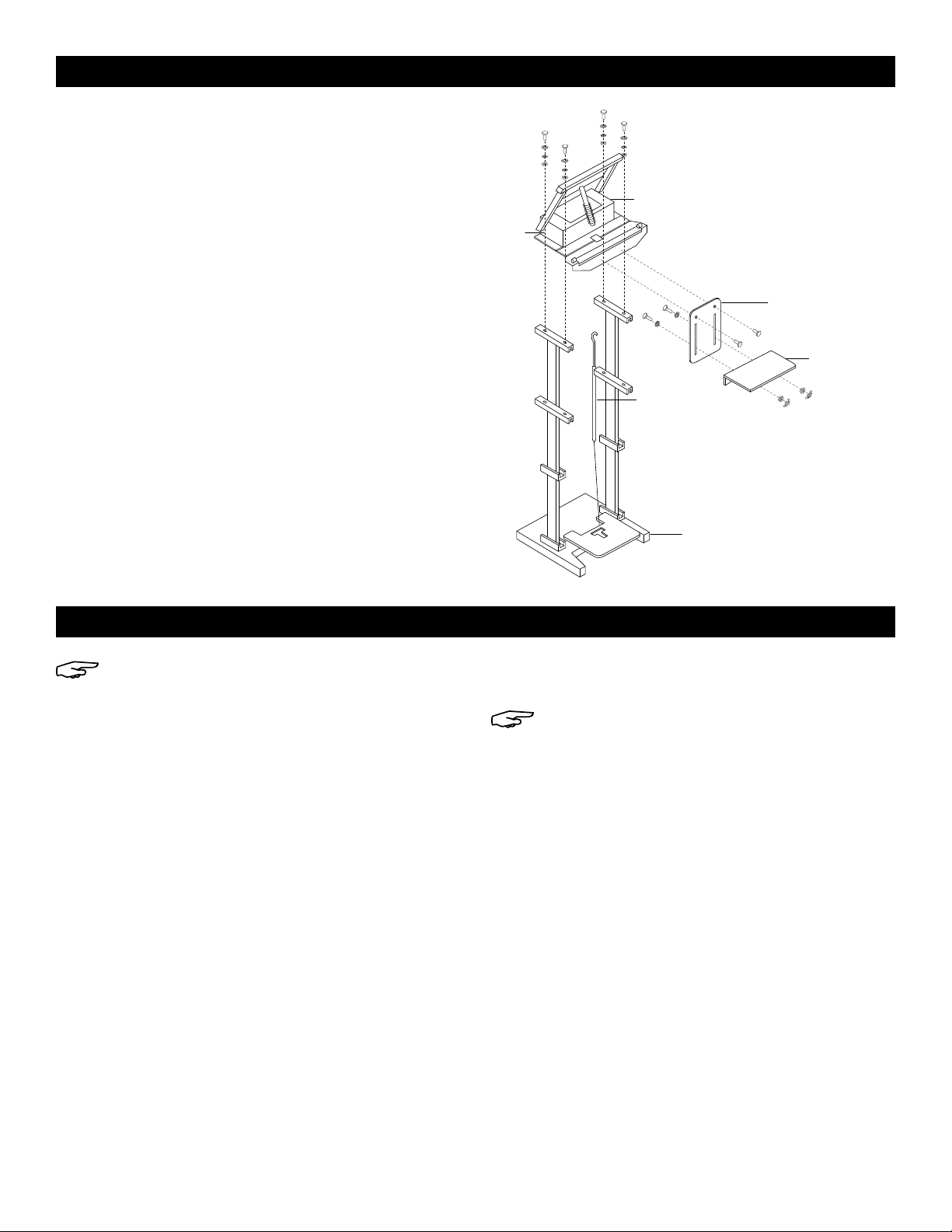

1. Position the pedestal on the floor standing upright.

2. Mount the complete sealer assembly to the top of

the pedestal and attach with four screws.

3. Position spring under the sealer’s upper level. The

pull-rod goes through the spring and is fastened to

the upper level.

4. With foot pedal metal rod in hand, gently push

down upper jaw to meet with lower jaw. While jaws

are compressed, reach under unit and hook the

metal foot pedal rod into the bottom of the spring

bar where the 1/2" hole is exposed.

5. With jaws still compressed, lift up the foot pedal to

45˚ angle and slide the metal foot pedal rod into

one of two pre molded slots. This will create tension

on the foot pedal and cause the pedal to stand

upright at 45˚.

6. Sealer is now ready to be used.

TO INSTALL OPTIONAL WORKING TRAY AND COVER

1. Remove center screws from bottom sealing jaw.

2. Install the working plate set A & B as shown.

OPERATION

ASSEMBLY

Control Set

Sealer

Assembly

Working Tray

Pull Rod

Working Plate

Pedestal