User’s Manual UPO1000 Series

9/96

3. Introduction of UPO1000

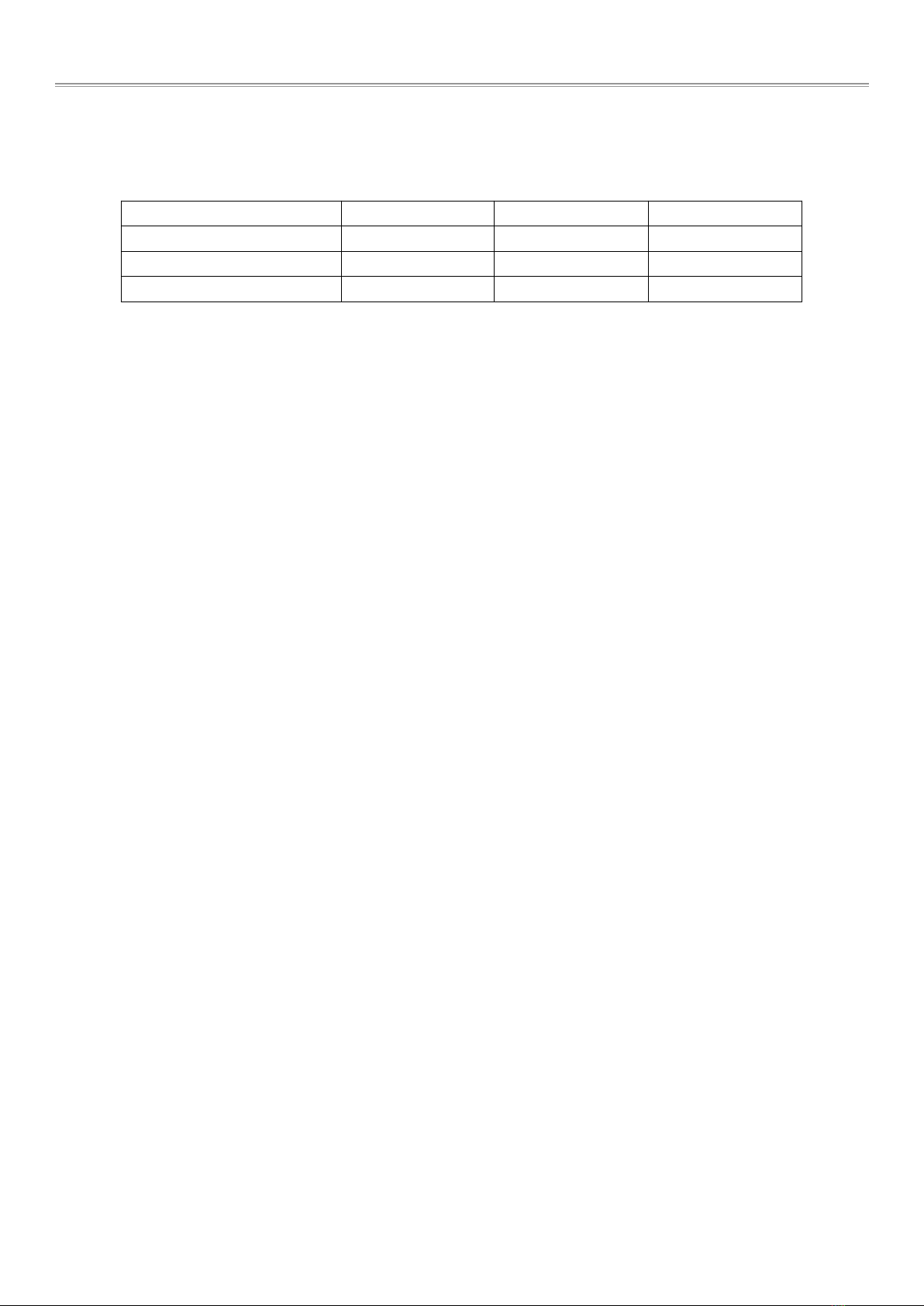

UPO1000 series digital phosphor oscilloscope includes three models.

UPO1000 series digital phosphor oscilloscope adopts UNI-T 3D technique Ultra Phosphor 2.0 with new

appearance upgrade and the function of deep storage, high waveform capture rate, real-time waveform

recording and playback and 256-level greyscale display.

The series is equipped with three levels of bandwidth of 50 MHz/100 MHz/200 MHz, real-time sampling

rate up to 2 GSa/s. The whole series are equipped with 4 channels, the maximum storage depth is 56

Mpts, up to 500,000wfms/s in Fast Acquire mode. Hardware real-time waveform uninterrupted recording

and waveform analysis up to 120,000 waveform frames; support DVM module, rich trigger and bus

decoding functions, and support full memory hardware real-time decoding.

It widely used in many fields, including communication, semiconductor, computer, IC design,

instrumentation, industrial electronics, consumer electronics, automotive electronics, field

maintenance and R&D/education.

Main Features

Analog channel bandwidth: 200 MHz, 100 MHz, 50 MHz

Analog channel number: 4

Maximum sampling rate: 2 GSa/s

Vertical scale: 500 μV/div-20 V/div

Low-base noise :<100 μVrms

Maximum storage depth up to 56 Mpts

Waveform capture rate of up to 500,000 wfms/s

The hardware can be continuous waveform recording 120,000 frame in real time

Automatic measurement of 36 waveform parameters, the measurement range divides into screen and

cursor area

Supports 7 digits hardware frequency meter measurement

DVM supports AC/DC TRMS (true virtual value) measurement

Waveform calculation function (FFT, add, subtract, multiply, divide, digital filter, logical operation and

advanced operation)

1M sampling points to enhance FFT function, it supports frequency setting, waterfall curve,

demodulation mode and marker measurement

Multiple trigger functions (edge, pulse width, video, slope, runt pulse, over-amplitude pulse, delay,

timeout, duration, setup hold, Nth edge and code pattern)

Supporting RS232, I2C, SPI trigger

Innovative RS232, I2C, SPI full memory hardware for real-time decoding

Ultra phosphor display effect, 256 grayscale display

7 inch WVGA(800×480)TFT LCD