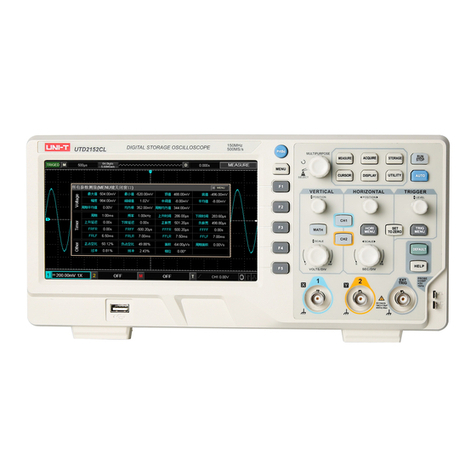

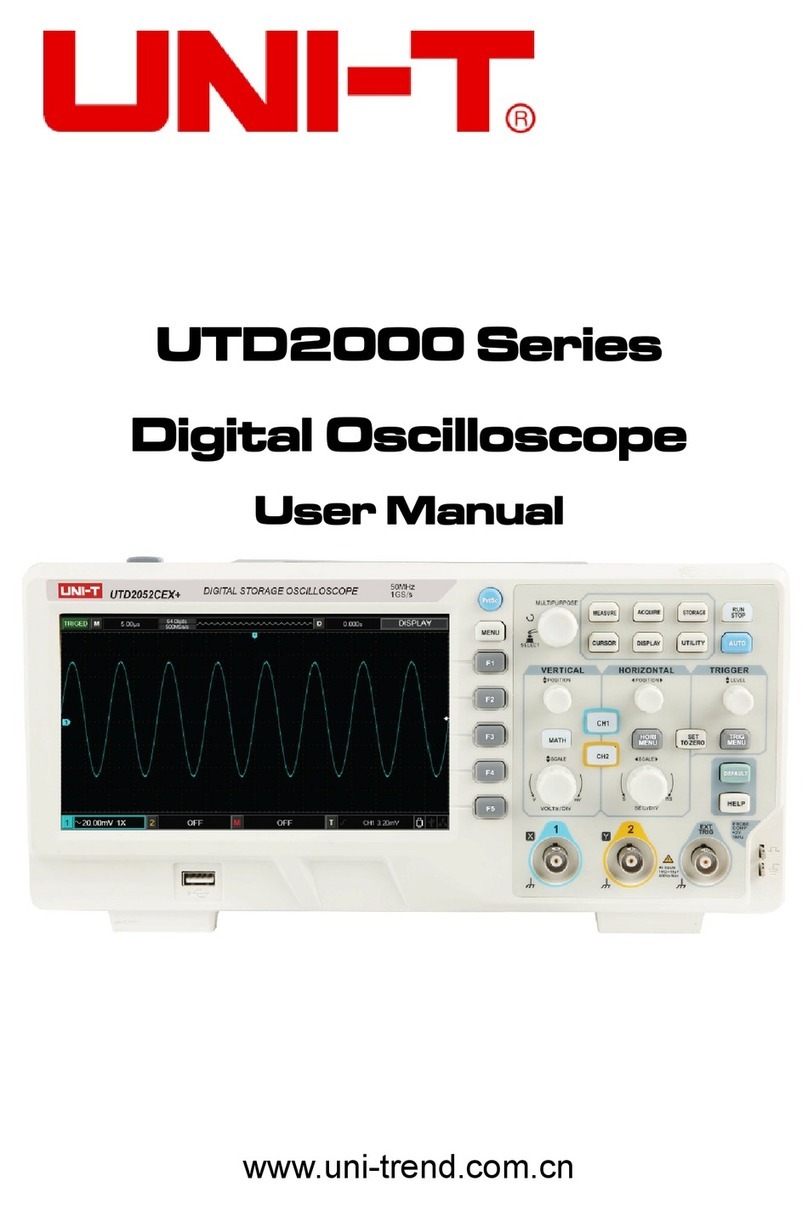

UTD2000 Series User Manual

3

If this product is sold or assigned by the original purchaser to a third party within three

years of purchase, the new owner should note that warranty is available for a period of

three years from the day the original purchaser acquired the product from Uni-T or an

authorized dealer. The probe, other accessories and fuses are not covered by warranty.

If any genuine defect is found during the valid warranty period, Uni-T has the option to

repair the defective product without any charge for parts or labor, or replace it with another

product (at the discretion of Uni-T). Uni-T may use parts, modules and replacement

products that are brand new or repaired to a good-as-new standard. All old parts, modules

and products that are removed during replacement become properties of Uni-T.

In this User Manual, “customer” means an individual or entity vested with the rights

hereunder. To enjoy the warranty service, the “customer” must report any defect to Uni-T

during the valid warranty period and make appropriate arrangement to allow servicing.

The customer should pack the defective product in a container and deliver it to a

maintenance centre specified by Uni-T. The customer should also prepay all freight cost

and provide a copy of the original sales receipt issued to the original purchaser. If the

product is to be delivered to an address within the country where the maintenance centre

operates, Uni-T shall pay the cost of returning the product to the destination, all freight,

custom duty, tax and other costs will be paid by the customer.

This warranty shall not apply to any defects or damages caused by accidental,

machine parts’ wear and tear, improper use, and improper or lack of maintenance. UNI-T

under the provisions of this warranty has no obligation to provide the following services:

a) Any repair damage caused by the installation, repair, or maintenance of the

product by non UNI-T service representatives.

b) Any repair damage caused by improper use or connection to an incompatible

device.

c) Any damage or malfunction caused by the use of a power source that does not

conform to the requirements of this manual.

d) Any maintenance on altered or integrated products (if such alteration or integration

leads to an increase in time or difficulty of product maintenance).

This warranty written by UNI-T for this product, and it is used to substitute any other

express or implied warranties. UNI-T and its distributors do not offer any implied

warranties for merchantability or applicability purposes.

For violation of this guarantee, UNI-T is responsible for the repair or replacement of

defective products is the only remedy available to customers. Regardless of whether

UNI-T and its distributors are informed that any indirect, special, incidental, or

consequential damage may occur, UNI-T and its distributors shall not be responsible for

any of the damages.