23

Contact surface of the clamp jaw shall keep clean and refrained from cleaning

by corrosive and coarse matters.

Refrain from any shock on the clamp meter , especially the junction surface of

the clamp jaw.

It is strongly recommended using our company's explosion-proof Clamp-on

Ground Resistance tester in dangerous occasions.

The explosion-proof product is prohibited to dismantle and replace the battery

in dangerous place.

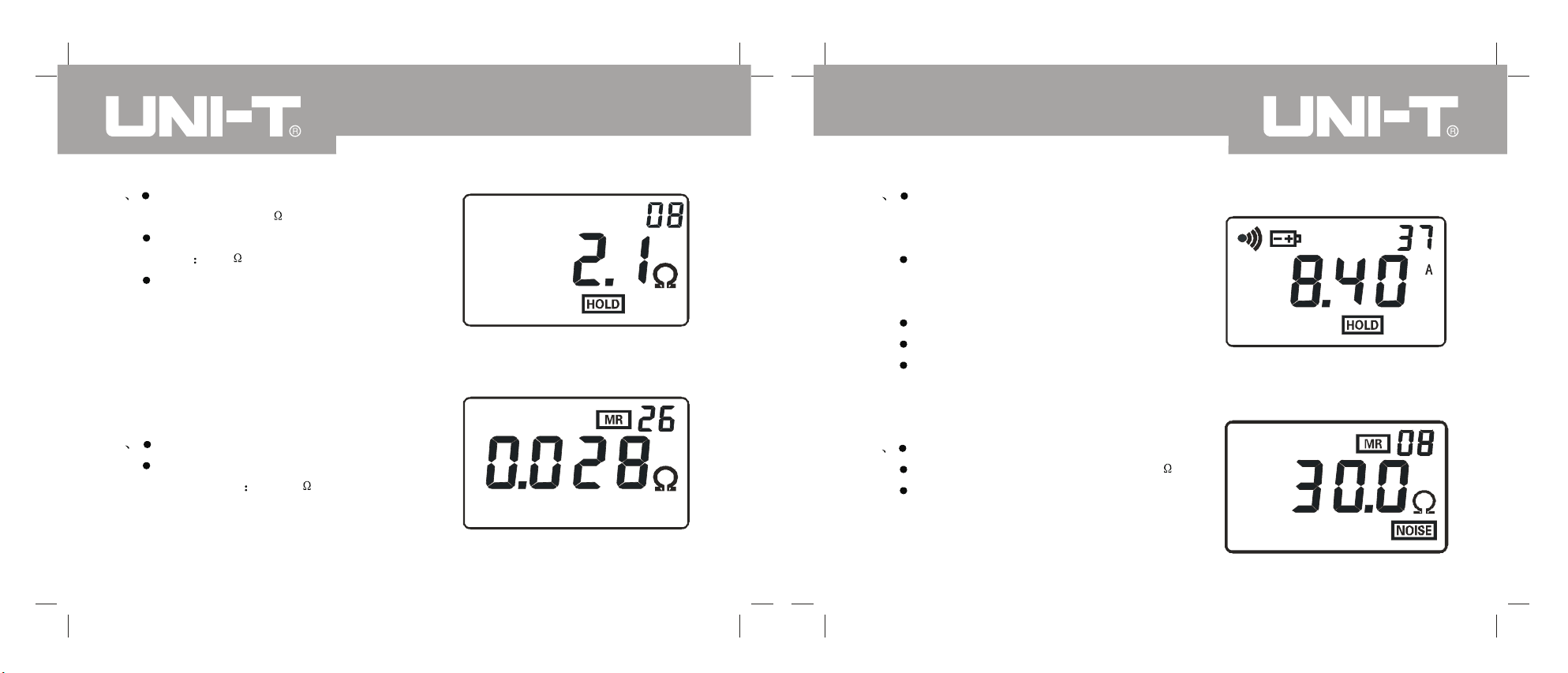

The clamp meter shall sound sporadically with light hum in measuring the

resistance, which is normal and shall be distinctive from the warning sound

beep--beep--beep-- .

Do not exceed the upper limits of the clamp meter in measuring the wire's

current.

Take out battery if do not use it for long time.

Dismantling, calibration and maintenance of the clamp meter shall be

conducted by the authorized qualified personnel.

If any danger might be resulted in continuation use by the inner reason of the

meter, stop using it immediately and pack it to the authorized qualified

institution to address the problem.

The contents labeled with * in the user manual shall be only applicable to

UT278A.

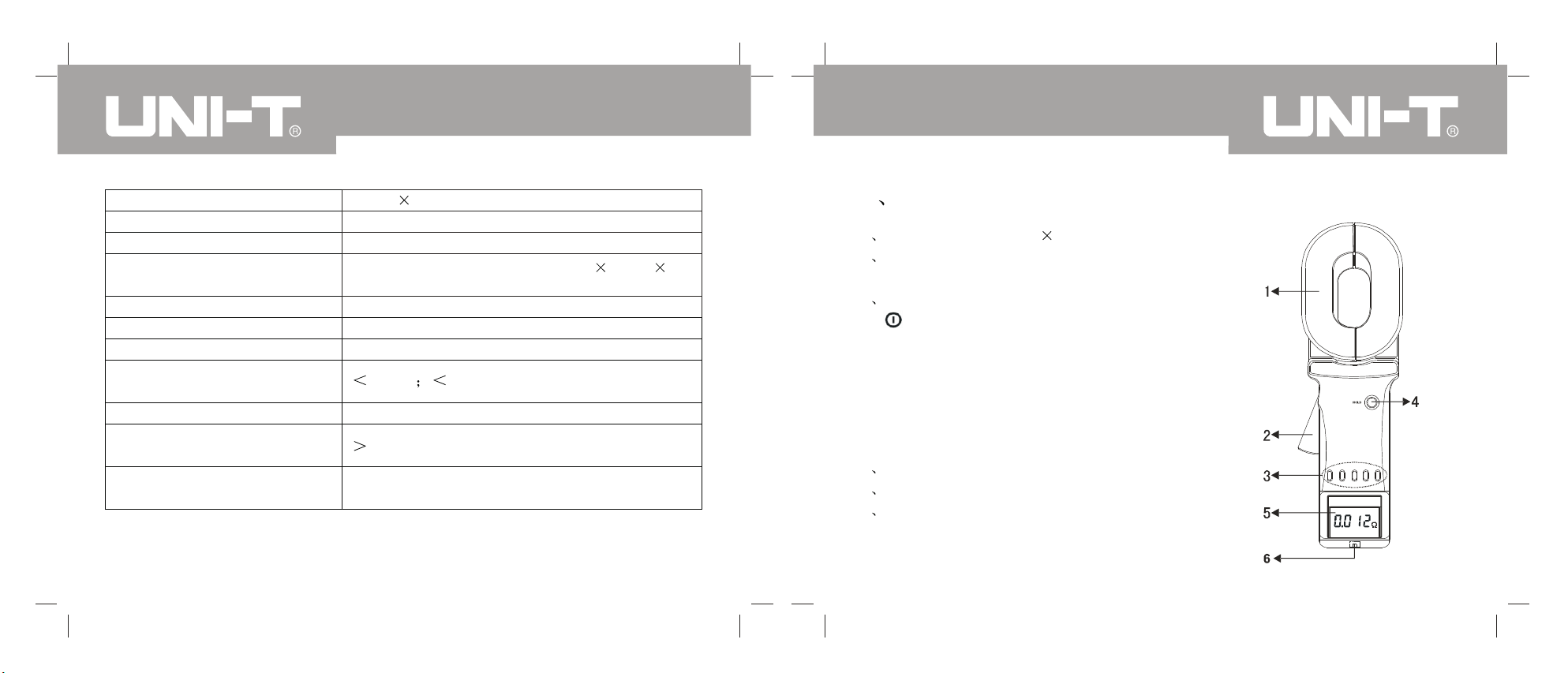

II Product Overview

The series of clamp-on ground resistance tester represents a significant

breakthrough of the traditional ground resistance measurement techniques and

apply widely to grounding resistance measurement in electricity,

telecommunication, meteorology, oilfield, architecture and industrial electric

equipment.

In measuring the ground system with loop, the series of clamp-on ground

resistance tester don't need to disconnect the ground down lead and any auxiliary

electrode, safe and fast, easy to use.

The series of clamp-on ground resistance tester can measure the grounding

problems with the traditional methods and apply to occasions traditional ways

can't measure as the tester measure the composite value of the grounding body

resistance and grounding down lead resistance.

UT276A 278A clamp-on ground resistance tester is the medium and high-end

UT276A/278A OPERATING MANUALUT276A/278A OPERATING MANUAL