Installation

ITC-Series Inverter Page 6 10/07/05

System Features

Inverter

The inverter consists of a sine wave inverter that supplies power when AC loads are applied. Depending on

your model, the inverter develops 2100, 3200 or 3600 watts of continuous power. Using TruSine®

technology, a very high quality sine wave is produced. Total harmonic distortion (THD) is less than 4.0

percent.

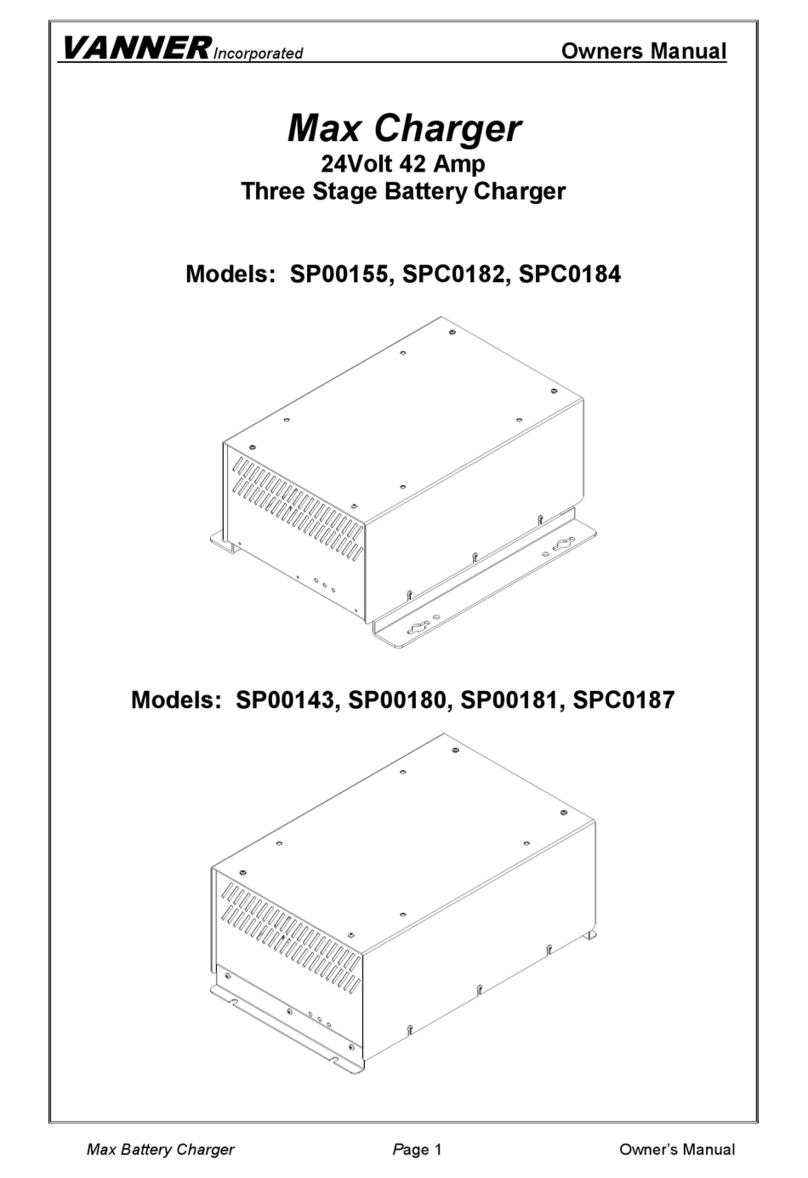

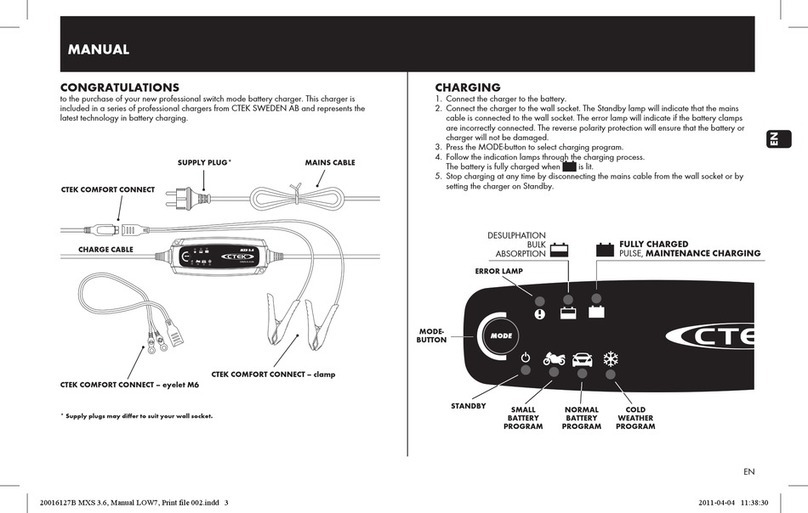

Battery Charger with Automatic Power Management

The high efficiency, multi-stage battery charger allows automatic charging of flooded lead acid and gel type

batteries. The efficient 0.85 power factor or PF, compared to typical 0.59PF on triac pulse type chargers,

allows full charger output from a 30-amp AC source. The system‟s Bulk, Absorption, and Float charge cycle

quickly charges and maintains the battery bank. An Equalization charge cycle is available for flooded lead

acid battery maintenance. In addition, there is an optional battery temperature sensor to reduce battery

float voltage as temperature increases above 25° Celsius.

Automatic Power Management (APM) monitors the AC Input current and will reduce the battery charger

output as needed to keep the AC input current below the preset APM Limit.

GenStart Contact

The GenStart feature provides a start/stop signal to control an automatic generator. The start/stop signal

consists of a contact closure to start the Gen. Start based on battery voltage of 12.3 (24.6) VDC. The

GenStart turns off when the battery charging current falling below 10 amps.

Low Battery or Fan On Contact

The Low Battery contact allows remote monitoring of the Inverter‟s battery status. The contact will close

when battery voltage falls below 11.0 (22.0) volts. This will alert the user to take appropriate measures to

avoid shutdown of the Inverter at 10.5 (21.0) VDC. The SP00172 offers a Fan On contact instead of the

Low Battery contact for turning on an external fan or blower when the ITC‟s fan is on.

Remote Power Switch

This loop between Options Terminal 7 and 8 (left side of Options Terminal) allow remote control of the

system On/Off. Tying these two terminals together or optionally, tying the terminal 7 (Remote Switch) to

battery ground applies power to the unit.

Note: The Front Panel switch will always overrule the remote switch in terms of disabling the unit.

System Control

The ITC contains a System ON/OFF Switch located in the front of the ITC. This switch is used to turn the

control power ON and OFF. This power switch also has a break out loop for a series switch that can be

placed in a remote location from the unit (See Remote Power Switch above). A control microprocessor

provides a variety of protection interlocks, system fault detection/reporting/recovery, storage of system data

parameters, and high-speed data communications to the ITC Control/Display Unit. This Control/Display

Unit also has individual on/off switches for independent Inverter and Charger control. The ITC will protect

itself in the event of any overload, over temperature, high or low battery voltage condition.

ITC Control/Display Unit

The ITC Control/Display Unit is a user interface that is connected to the ITC Control Board via a 6-wire

modular cable. This Control/Display unit can be an integral part of the Inverter or can be removed and

mounted in a remote area to allowing remote system operation. Two of these units can talk to the System

Control Board one display would be configured as a Master, and the other as Slave. The configuration

switches on top of the Master allow programming of the Charger current, Automatic Power Management

and battery type settings.

NOTE: It should be noted that if the Control Display unit is taken out of the front of the unit, the cover plate