5

Table of Contents

General information................................................................... 6

1. Main functions ................................................................... 7

2. Basic concepts................................................................... 8

3. Installation topology............................................................... 14

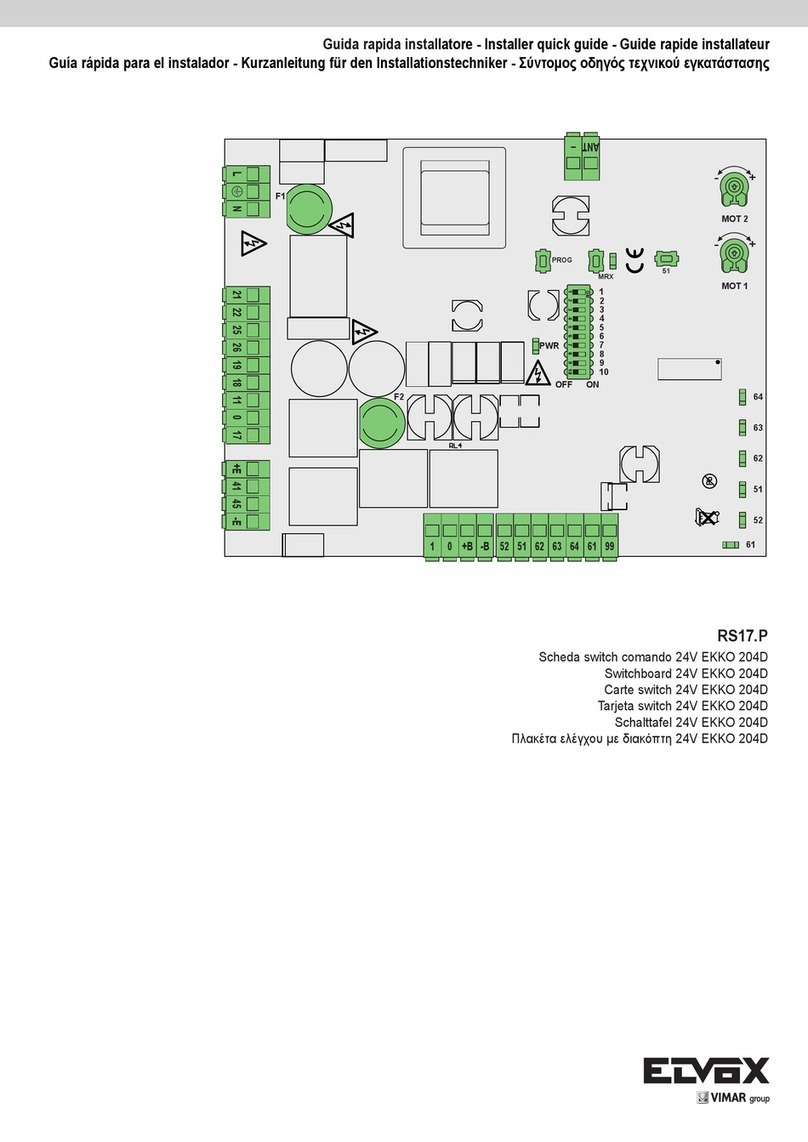

3.1 Installation of bus systems................................................................... 15

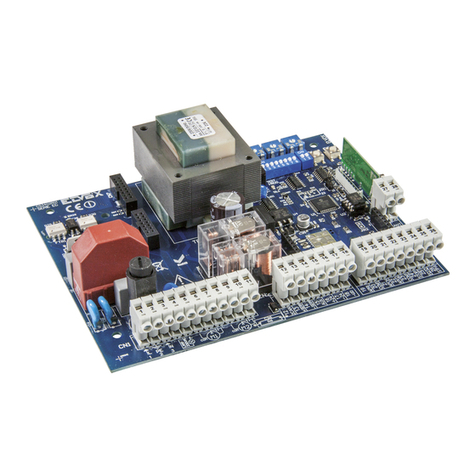

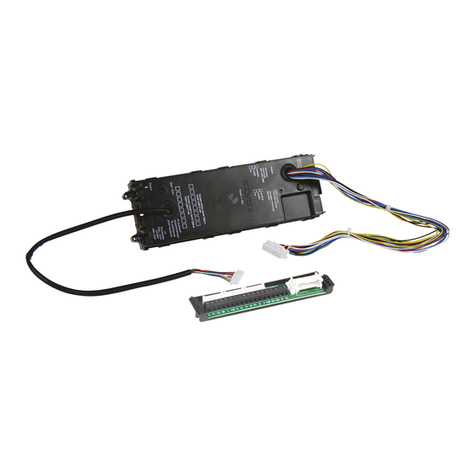

3.2 Description of terminals ..................................................................... 18

3.3 Putting the system into service ................................................................ 19

4. Main configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

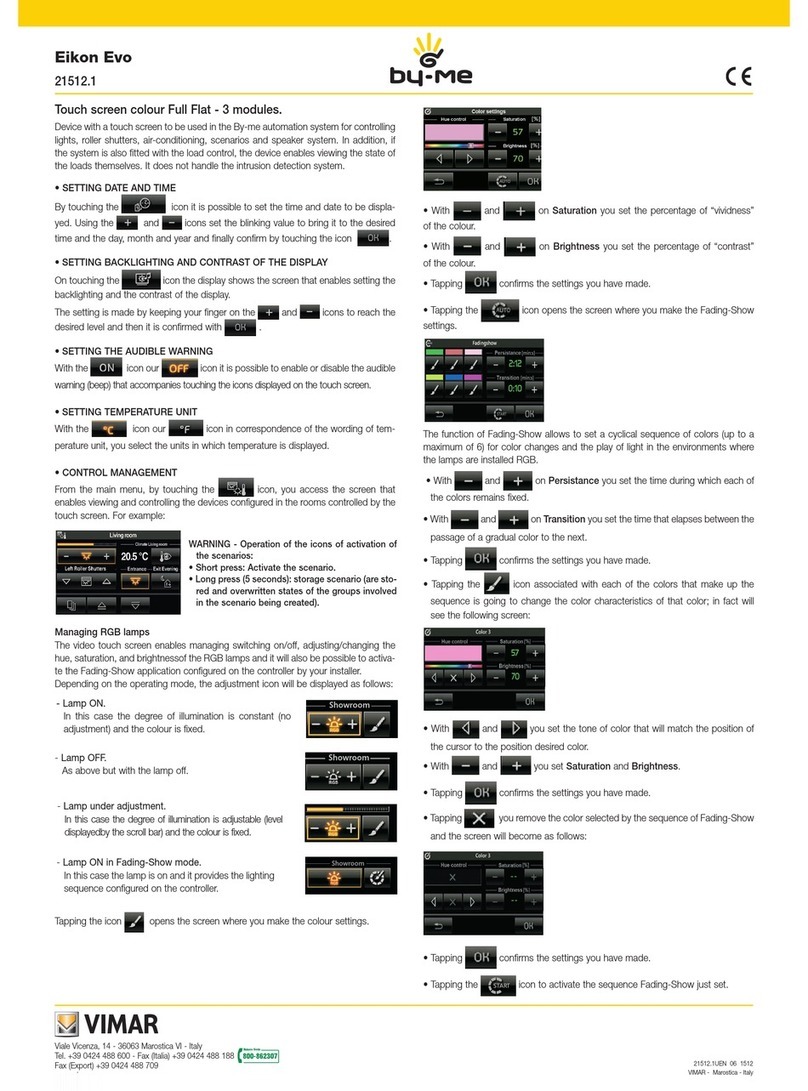

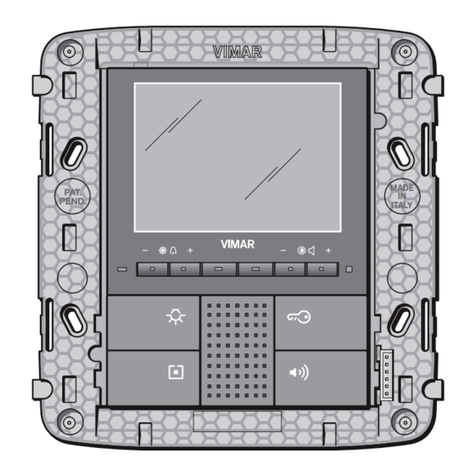

4.1 Navigating the control unit menus ............................................................. 20

4.2 Initial switch-on ........................................................................... 21

4.3 Main screens of the control unit ............................................................... 23

4.4 Settings menu ............................................................................ 24

4.5 Configuration menu ........................................................................ 29

5. HVAC control .................................................................... 55

5.1 General settings........................................................................... 55

5.2 Operating modes.......................................................................... 63

5.3 Programming............................................................................. 65

6. Scenarios ....................................................................... 66

6.1 Creating a scenario . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

6.2 Activating a scenario ........................................................................ 68

6.3 Renaming a scenario ....................................................................... 68

6.4 Deleting a scenario ........................................................................ 69

6.5 Cancelling a button associated with the scenario................................................... 69

6.6 Remote access to scenarios ................................................................. 69

7. Load control ..................................................................... 70

7.1 Functionality .............................................................................. 70

7.2 Power management ........................................................................ 71

7.3 Load management ......................................................................... 73

7.4 LED signals of the module 01855 .............................................................. 75

8. Programming events .............................................................. 76

8.1 Programming............................................................................. 76

8.2 Operation ............................................................................... 82

8.2 Example applications....................................................................... 83

9. Integration of the passive infrared presence detectors and the contacts interfaces ........... 87

10. Diagnostics and maintenance ...................................................... 88

10.1 Diagnostics and replacement of devices ........................................................ 88

10.2 Remote communications management ........................................................ 89

10.3 Control unit software release ................................................................. 89

11. Installation rules .................................................................. 90

12. Compliance with regulations ........................................................ 90

13. Supplementary declarations made by the manufacturer ................................. 90