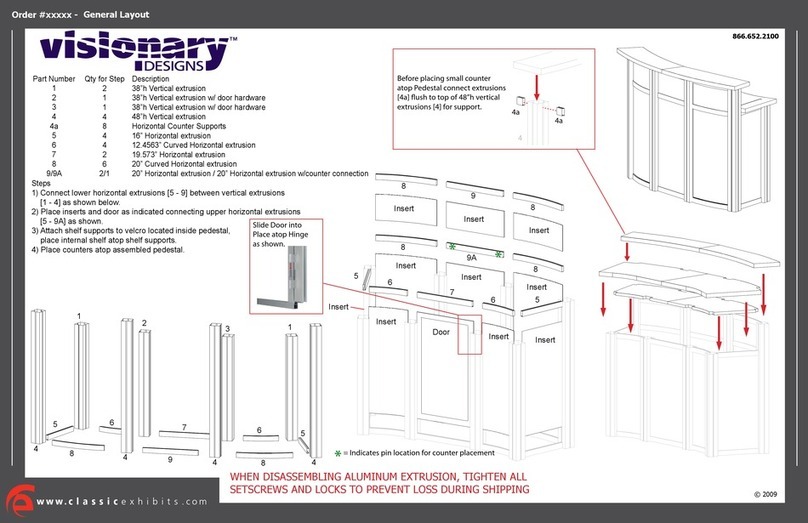

VISIONARY DESIGNS 41444 User manual

Other VISIONARY DESIGNS Indoor Furnishing manuals

VISIONARY DESIGNS

VISIONARY DESIGNS MOD-1185 Manual

VISIONARY DESIGNS

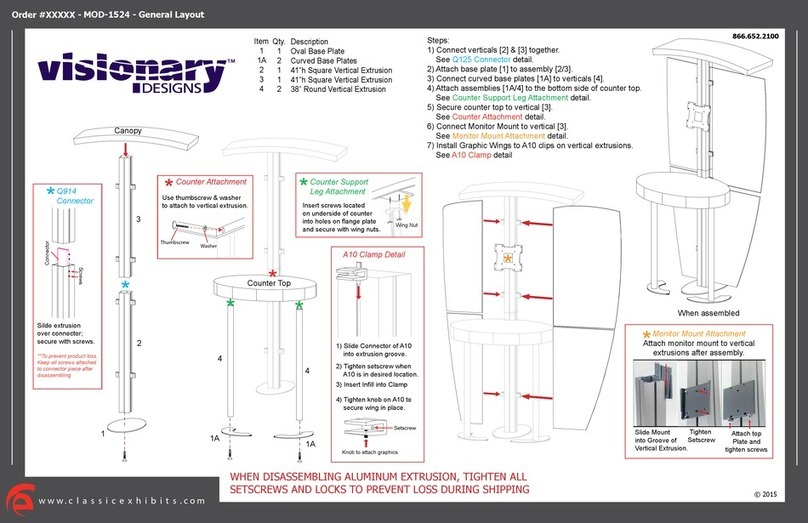

VISIONARY DESIGNS MOD-1524 Manual

VISIONARY DESIGNS

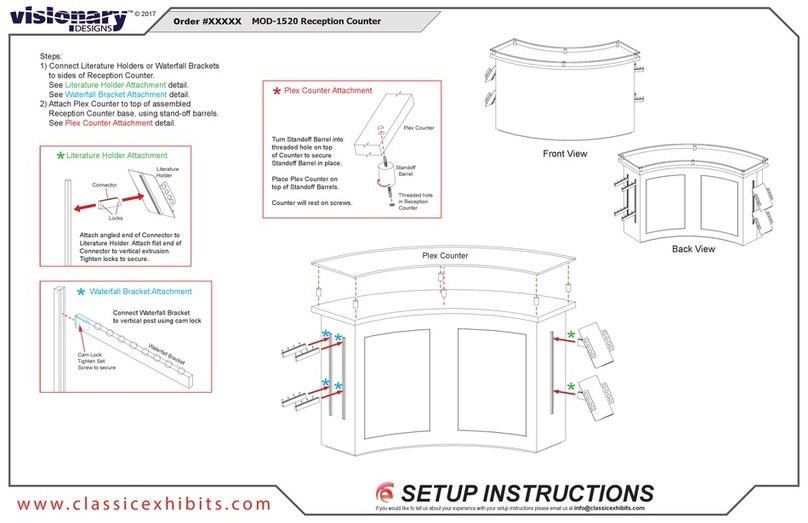

VISIONARY DESIGNS MOD-1520 User manual

VISIONARY DESIGNS

VISIONARY DESIGNS MOD-1514 Manual

VISIONARY DESIGNS

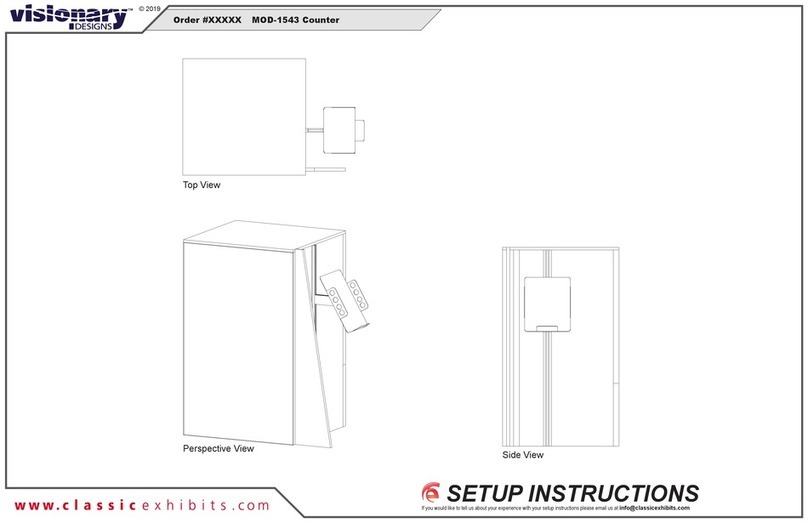

VISIONARY DESIGNS MOD-1543 Manual

VISIONARY DESIGNS

VISIONARY DESIGNS LTK-1001 User manual

VISIONARY DESIGNS

VISIONARY DESIGNS RE-1067 Manual

VISIONARY DESIGNS

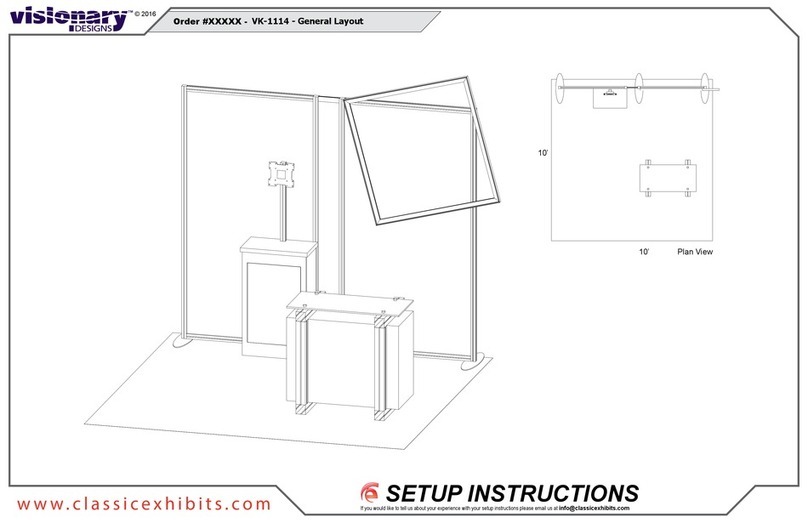

VISIONARY DESIGNS VK-1114 Manual

VISIONARY DESIGNS

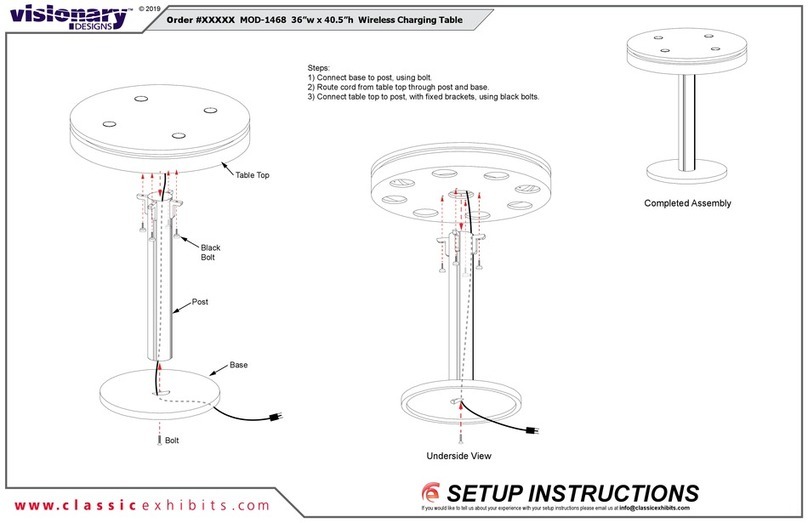

VISIONARY DESIGNS MOD-1468 User manual

VISIONARY DESIGNS

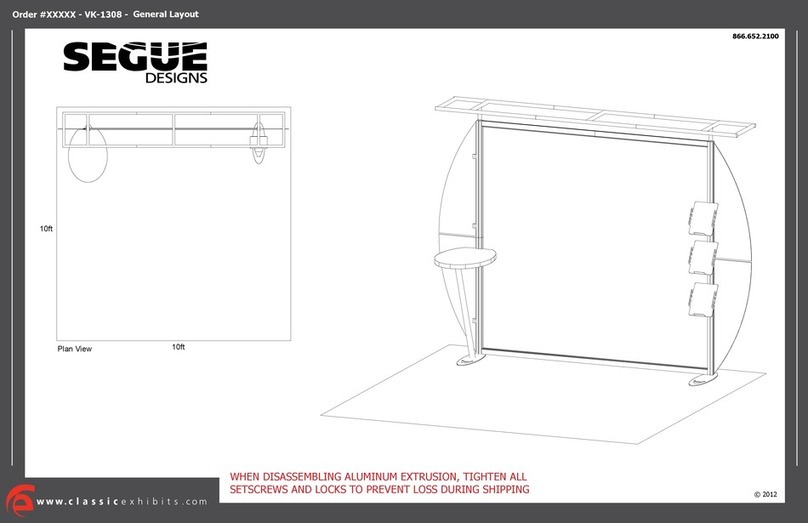

VISIONARY DESIGNS SEGUE VK-1308 User manual

VISIONARY DESIGNS

VISIONARY DESIGNS MOD-1450 Manual

VISIONARY DESIGNS

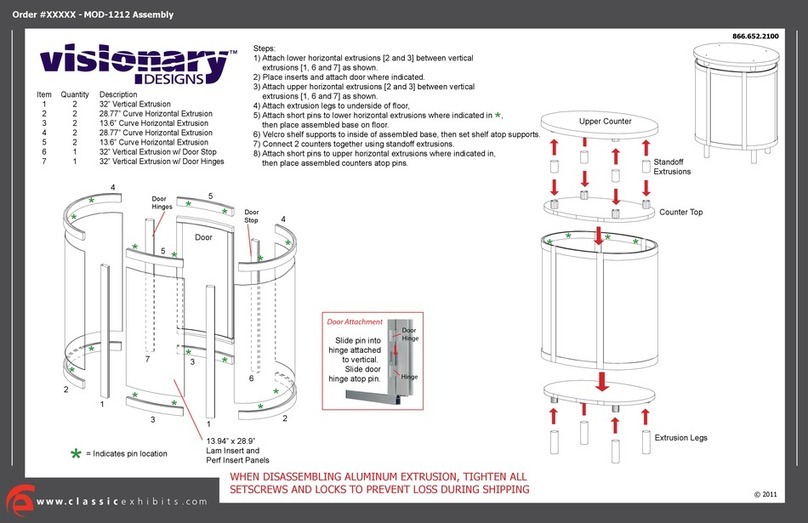

VISIONARY DESIGNS MOD-1212 User manual

VISIONARY DESIGNS

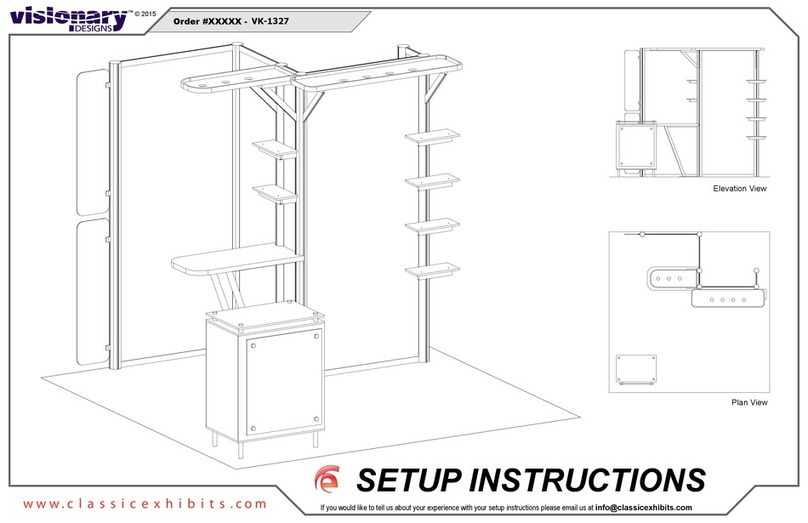

VISIONARY DESIGNS VK-1327 Manual

VISIONARY DESIGNS

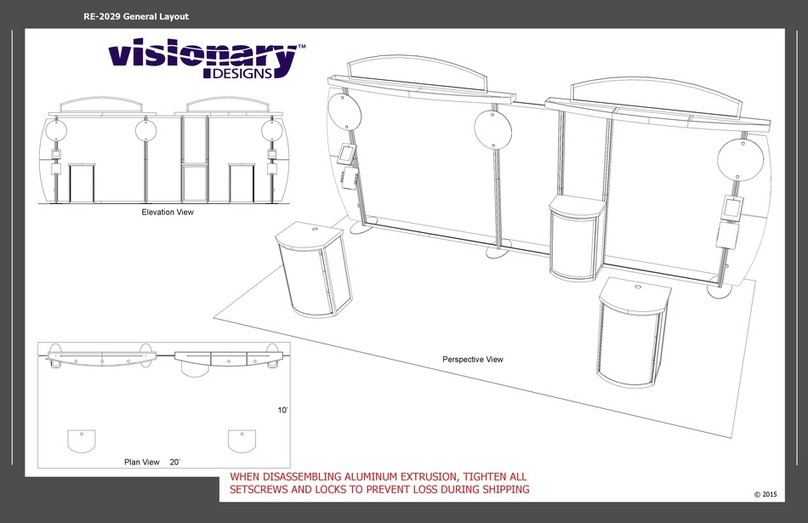

VISIONARY DESIGNS RE-2029 User manual

VISIONARY DESIGNS

VISIONARY DESIGNS VK-1032 Manual

VISIONARY DESIGNS

VISIONARY DESIGNS MOD-1177 User manual

VISIONARY DESIGNS

VISIONARY DESIGNS VK-2922 Manual

VISIONARY DESIGNS

VISIONARY DESIGNS MOD-1243 Manual

VISIONARY DESIGNS

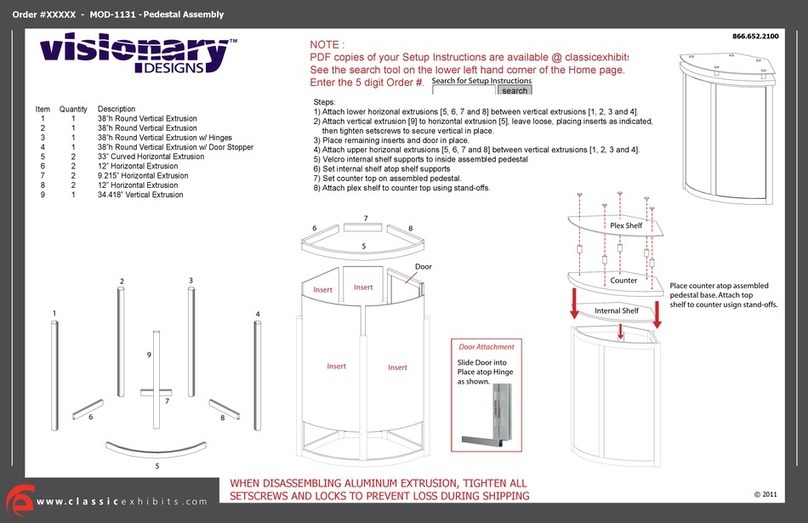

VISIONARY DESIGNS MOD-1131 User manual

VISIONARY DESIGNS

VISIONARY DESIGNS MOD-1143 User manual

Popular Indoor Furnishing manuals by other brands

Safavieh Furniture

Safavieh Furniture COF4203 Care and maintenance

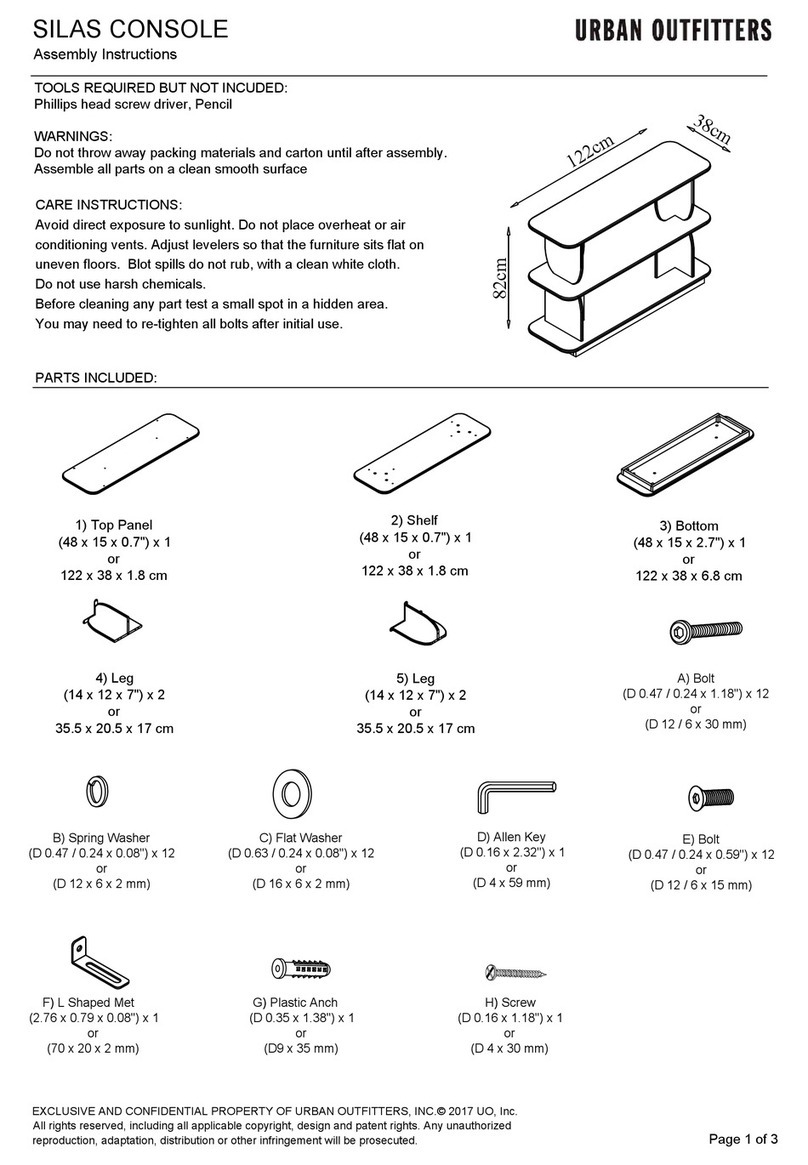

URBAN OUTFITTERS

URBAN OUTFITTERS Lila 65313553 Assembly instructions

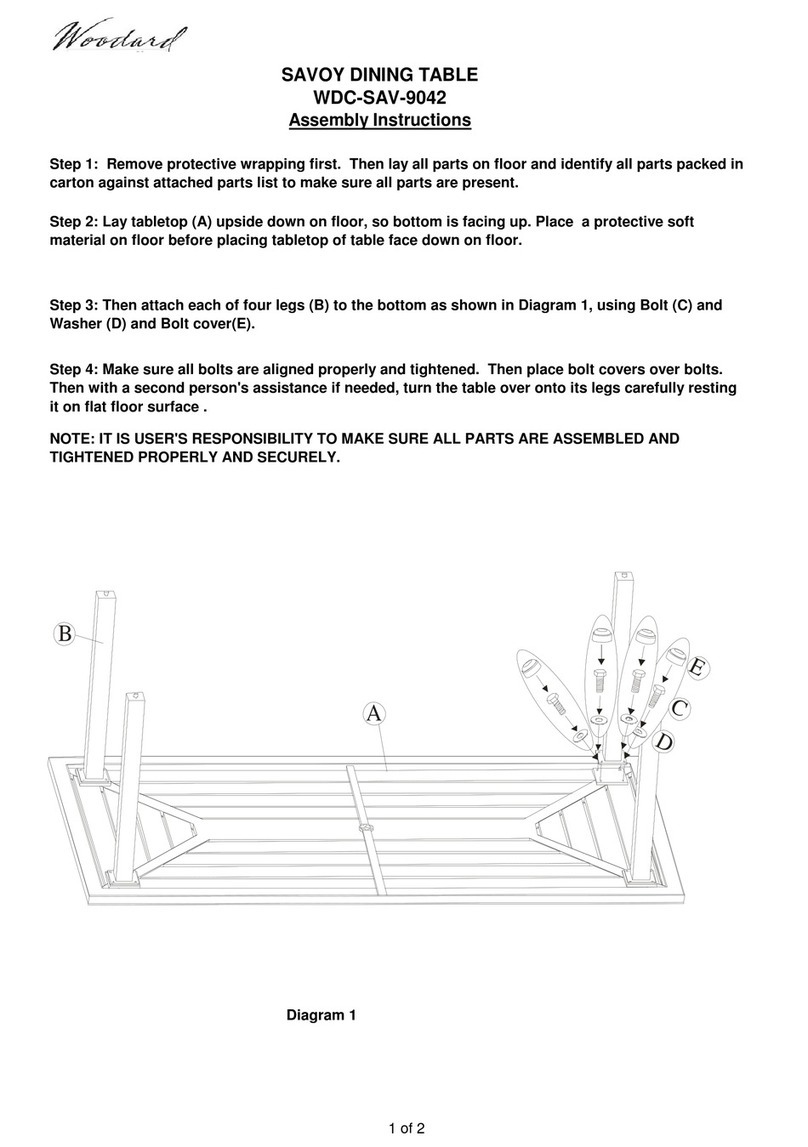

Woodard

Woodard SAVOY DINING TABLE WDC-SAV-9042 Assembly instructions

Kenroy Home

Kenroy Home SURREY 65132 Use and care guide

Leigh Country

Leigh Country TX 93486 quick start guide

Bensons for Beds

Bensons for Beds CASSIA STK721501 Assembly instructions