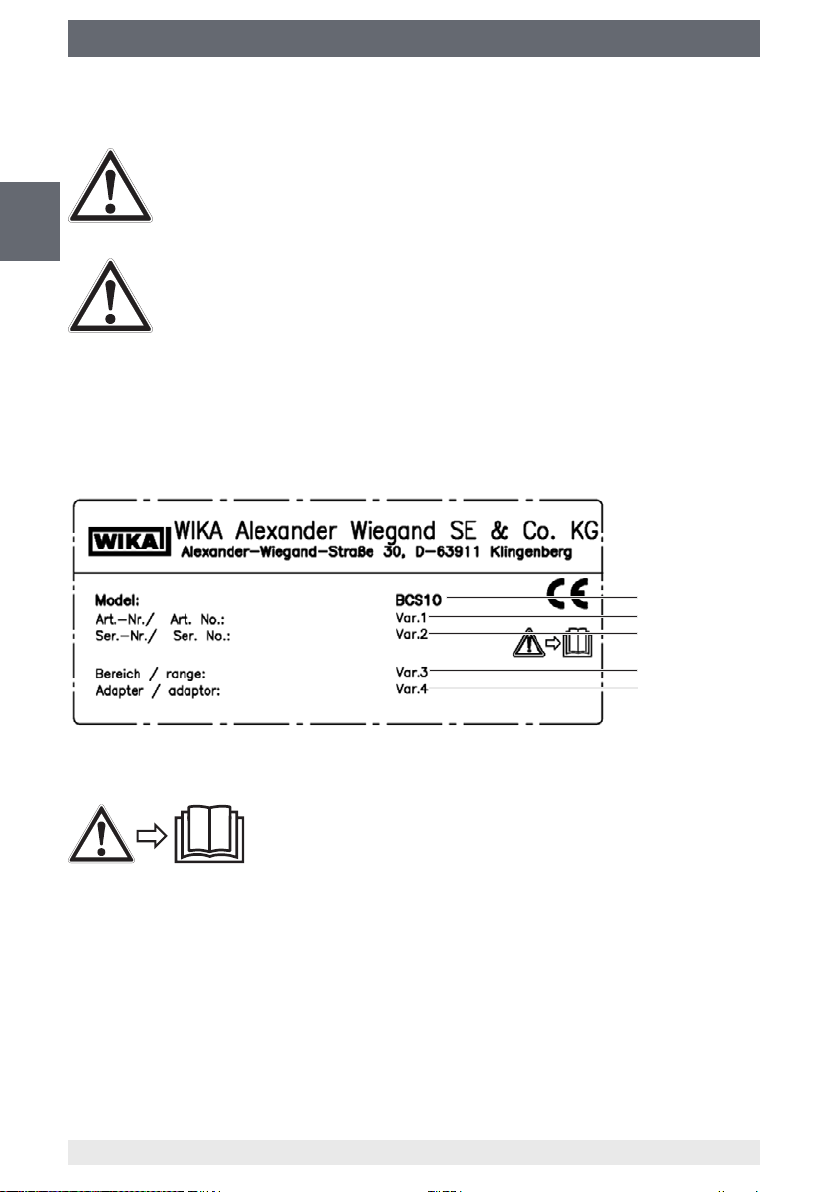

6WIKA operating instructions calibration system, model BCS10

14051046.02 07/2019 EN/DE/FR/ES

EN

2. Safety

If the instrument is transported from a cold into a warm environment, the formation of

condensation may result in instrument malfunction. Before putting it back into operation,

wait for the instrument temperature and the room temperature to equalise.

The manufacturer shall not be liable for claims of any type based on operation contrary

to the intended use.

2.2 Personnel qualication

WARNING!

Risk of injury should qualication be insucient!

Improper handling can result in considerable injury and damage to equip-

ment.

■

The activities described in these operating instructions may only be

carried out by skilled personnel who have the qualications described

below.

■

Keep unqualied personnel away from hazardous areas.

Skilled personnel

Skilled personnel are understood to be personnel who, based on their technical training,

knowledge of measurement and control technology and on their experience and

knowledge of country-specic regulations, current standards and directives, are capab-

le of carrying out the work described and independently recognising potential hazards.

Special operating conditions require further appropriate knowledge, e.g. of aggressive

media.

2.3 Additional safety instructions for SF₆ gas in switchgear

The plant operator must ensure that the handling of SF₆ gas is only carried out by

a qualied company or by qualied persons which have been specially trained in

accordance with IEC 61634, section 4.3.1 or IEC 60480, section 10.3.1.

Valid standards and directives for SF₆ gas

Installation, assembly, commissioning:

■

IEC 61634 (Handling of SF₆ gas)

■

IEC 60376 (New SF₆ gas, technical grade SF₆ gas)

■

IEC 60480 (Used SF₆ gas)

■

CIGRE report 276, 2005 (Practical SF₆ gas handling instructions)

Leaks during operation:

■

IEC 60376 (New SF₆ gas, technical grade SF₆ gas)

■

IEC 60480 (Used SF₆ gas)

■

CIGRE 2002 (“SF₆ gas in the electrical industry”)