Contents

WIKA Operating Instruction, Model CPH7600 3

14051628.01 07/2012 GB/D

C

C

Co

o

on

n

nt

t

te

e

en

n

nt

t

ts

s

s

1General Information ............................................................................................................. 5

2Safety .................................................................................................................................. 6

2.1 Intended use ........................................................................................................................ 7

2.2 Personnel qualification ......................................................................................................... 7

2.3 Special hazards ................................................................................................................... 8

2.4 Labelling / Safety marks ...................................................................................................... 9

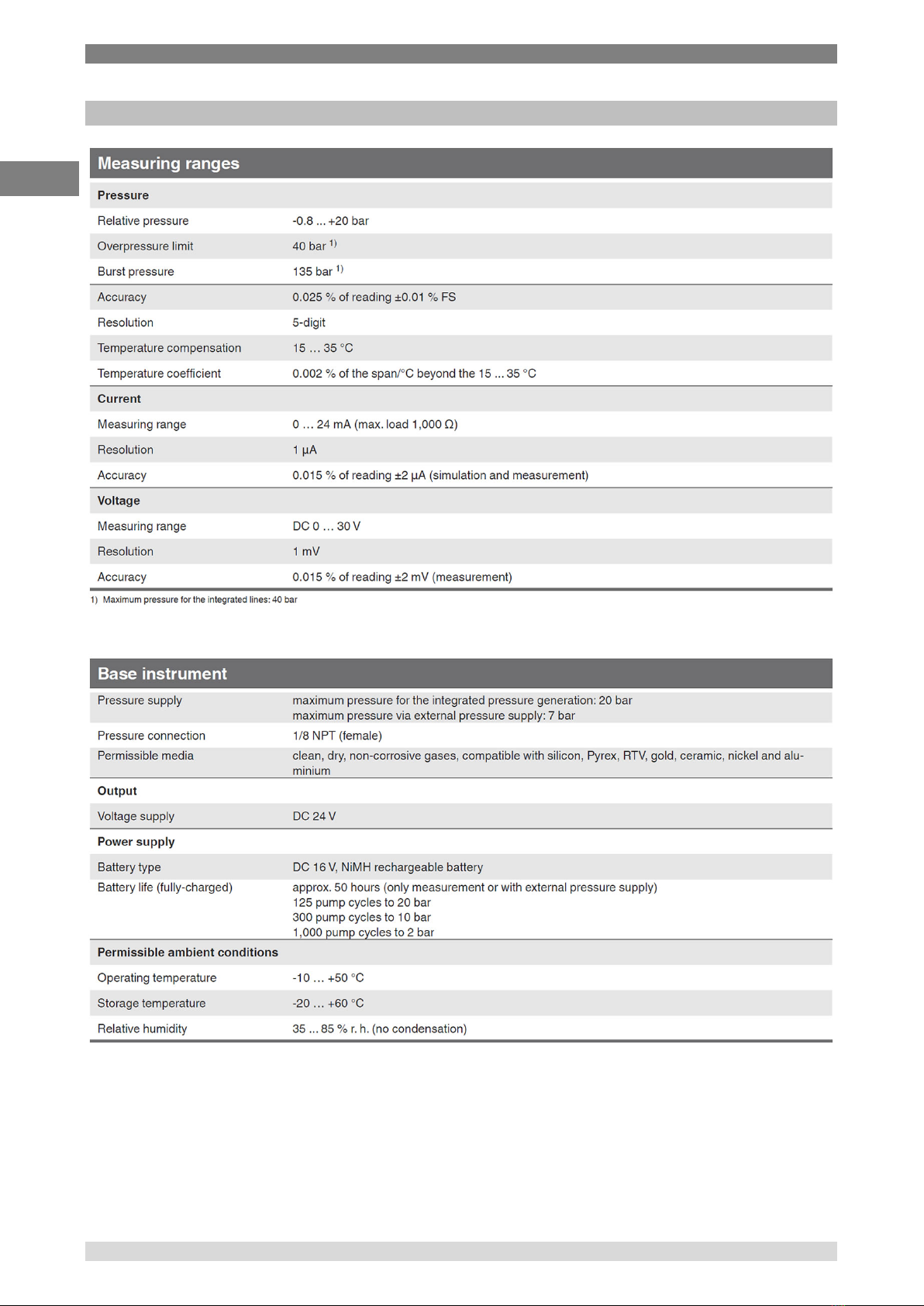

3Specifications .................................................................................................................... 10

4Design and Function .......................................................................................................... 13

4.1 Description ........................................................................................................................ 13

4.2 Scope of delivery ............................................................................................................... 13

4.3 Power supply ..................................................................................................................... 13

4.4 CPH7600 hand-held pressure calibrator, pressure connections ........................................ 14

4.5 CPH7600 hand-held pressure calibrator, keypad ............................................................... 15

4.6 Menu-Structure .................................................................................................................. 16

5Transport, packaging and storage ..................................................................................... 18

5.1 Transport ........................................................................................................................... 18

5.2 Packaging .......................................................................................................................... 18

5.3 Storage .............................................................................................................................. 18

6Commissioning, operation ................................................................................................. 19

6.1 Calibrator display ............................................................................................................... 19

6.1.1 Main display functionality ................................................................................................... 19

6.1.2 Main menu Functionality .................................................................................................... 20

6.2 Using the backlighting........................................................................................................ 21

6.3 Using the "ZERO" function................................................................................................. 21

6.3.1 External pressure module (not absolute) ........................................................................... 21

6.3.2 External pressure module (absolute) ................................................................................. 21

6.4 Other menu controlled functions ........................................................................................ 21

6.4.1 Setting the contrast ............................................................................................................ 22

6.4.2 Locking and unlocking configurations ................................................................................ 22

6.4.3 Saving and recalling settings ............................................................................................. 22

6.4.4 Setting auto shut-off parameters ........................................................................................ 23

6.4.5 Activating and deactivating a display ................................................................................. 23

6.4.6 Damping ............................................................................................................................ 23

6.4.7 Pump limit .......................................................................................................................... 23

6.4.8 HARTTM-Resistor ............................................................................................................... 24

6.5 Basic Setup and initial pressure generation ....................................................................... 24

6.6 Measuring pressure ........................................................................................................... 24

6.6.1 Media compatibility ............................................................................................................ 25

6.6.2 Measuring pressure with external modules ........................................................................ 25

6.7 Measuring and sourcing current (4 ... 20 mA) .................................................................... 26

6.8 Measuring voltage ............................................................................................................. 27

6.9 Performing a pressure switch test ...................................................................................... 28

6.10 Calibrating transmitters ...................................................................................................... 30

6.10.1 Using the mA measurement function ................................................................................. 30

6.10.2 Calibrating a pressure-to-current transmitter ...................................................................... 31

6.10.3 %-Error function ................................................................................................................. 32

6.11 MIN/MAX value capture ..................................................................................................... 35

7Maintenance, cleaning and recalibration ............................................................................ 36

7.1 Maintenance ...................................................................................................................... 36

7.2 Cleaning ............................................................................................................................ 36

7.3 Recalibration ..................................................................................................................... 36

8Faults ................................................................................................................................ 37