© by WilTec Wildanger Technik GmbH Seite 7

http://www.wiltec.info

that after each egg is put into the grille, there should be 5-l0mm clearance

at least for convenient turning ofhatching egg, inject 300ml water into the

base after the hatching egg is put, check once for every day so that the incu-

bator is not short of water. Every water injection shall not be more than 100-

l50ml, take down the date ofplacing hatching egg so as to well control the

hatching time. It's best to place the incubator on 60-80CM table for conve-

nient observation.

5. When closing the cover, the rod must insert the shifting slot of movable egg

tray, so that the egg tray can shift normally.

6. Switch on the power supply after closing the cover, and set the temperature

according to Push-Button Instruction and Incubation Technology.

Ifthe user has no time to care about the temperature, the temperature can

be set at 38°Cfrom the first day of incubation to first day of hatching, and it

can be set as 37.5 -37.8°C since the following day of hatching.

7. It moves to hatching tray 3 days earlier than incubation period for all poultries.

8. It usually takes 3--I days less than the number ofincubation days for egg

tray replacement, replace the egg tray once one or two hatching eggs are

seen hatched, and then take the movable egg tray and grille out.

9. After closing the cover and switching on the power supply, the hatching

situation can be observed.

III. Important for Safety

1.0nly the power supply marked on the incubator can be used,

2.Don't put any goods on the wire, the power line ofincubator shall be placed

where it won't be stepped on or make people trip and fall;

3. Make sure that the socket and extension line in use have no overload, other

-wise, it may cause fire or electric shock;

-I. If the incubator is smoking, or sending abnormal smell or unusual noise,

please cut off the power supply and pull down the power line to stop the

fault, after that, contact the agency or maintenance center;

5.Please don't touch the power line with wet hand, or it may cause electric shock;

6.This incubator can't be exposed to rain and sunshine;

7. Make sure that the power supply is switched off before cleaning the incubator;

8. The incubator shall be placed in room where is ventilated without vibratory

equipment, it can't be placed in room with fast air movement or room with

harmful and noxious chemicals and other pollutants.

IV. Push-button Instruction:

1. SET:

A: Push SET once to enter temperature control set, push <+> or <-> to adjust

parameter, push<+>or<-> for 3s to enter fast adjustment mode, push SET

again to exit from setting state.

B: Push SET for 3s to enter system menu set, push <+> or <-> to select menu

in need of adjustment, then push SET again to enter relative parameter sett-

ing state, push <+> or <-> to adjust parameter in need of modification, push

RST to exit after adjustment, or the system will exits after 5s delay.

2.<+>: Up button

3.<->: Down button

Operation Instruction:

Indicating lamp state instruction:

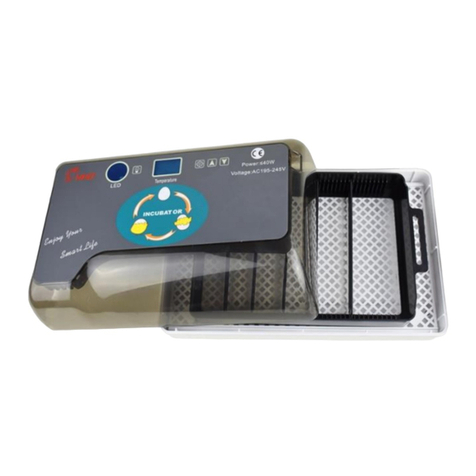

WORK lamp on the left side of display screen is made as work indicating lamp,

LED normally on means it's in heating state.SET lamp on the left side of dis-

play screen is used for indicating lamp set, LED normally on means it's in

setting state.

Function instruction:

{HU,HD:

Parameter HU and HD is set by factory, the user unless the professional is not

allowed to adjust it.

{Temperature correction set:

When measuring temperature deviates from reference temperature, tempe-

rature correction <CA> function shall be used to make the measuring value

in accordance with reference temperature, temperature after correction