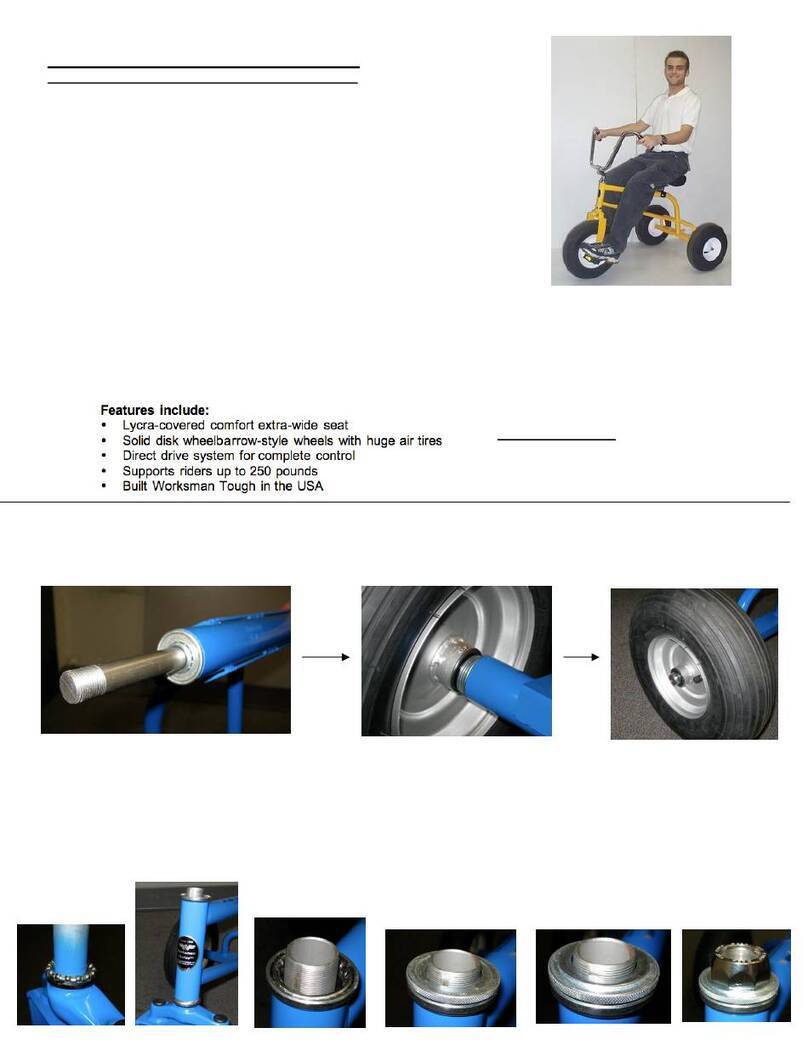

MAINTENANCE TIPS:

Always inspect your Worksman Cycle to ensure that all nuts, bolts, screws and hardware are tight and that no parts are

worn or damaged. Do not attempt to straighten bent forks or frames.

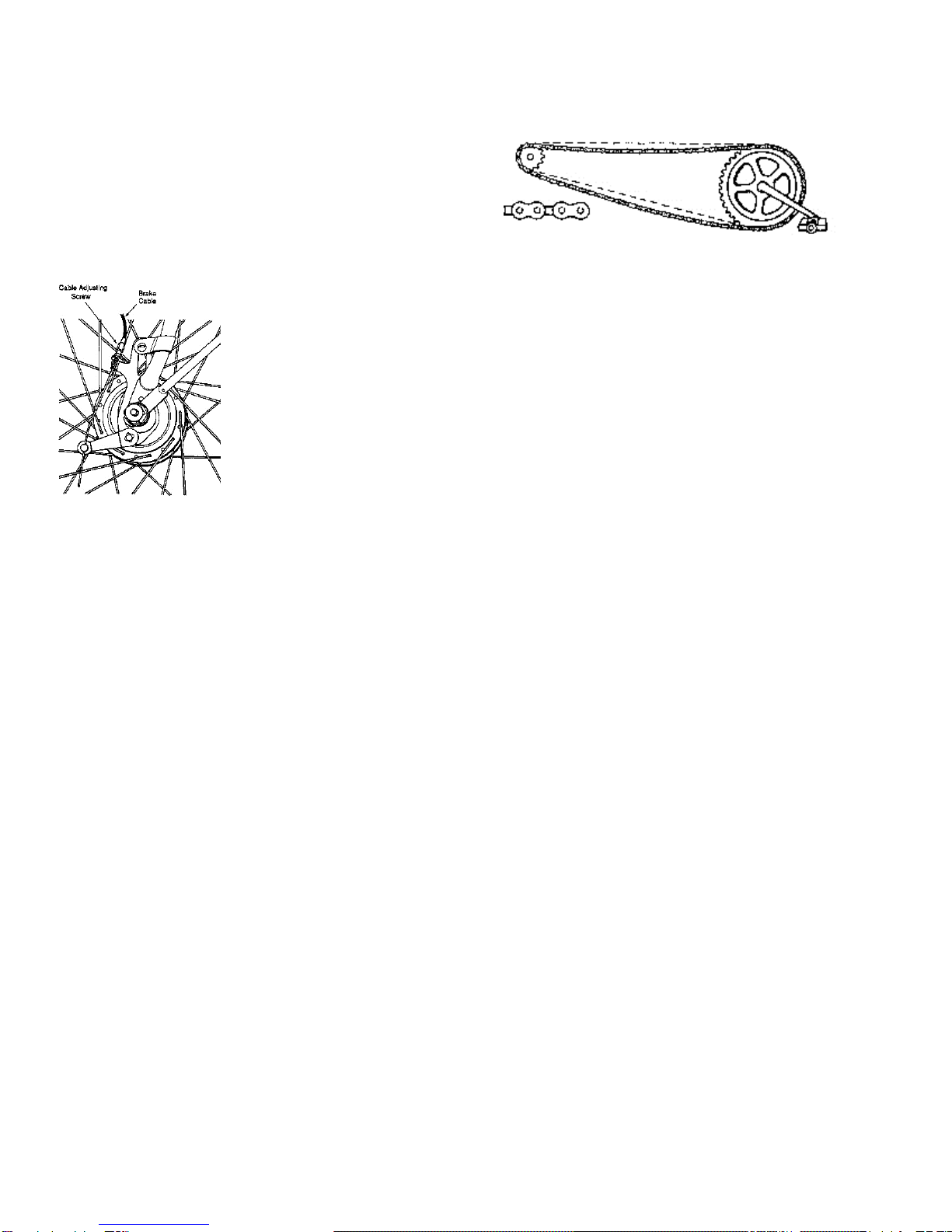

Chain:

Lubricate chain once a month or as needed with light oil.

Replace sprockets when teeth become worn, bent or broken.

Keep chain adjusted so there is no more than 3/8”slack. Note

that we make the chains tight at the factory, as we do know

they will stretch during the break-in period.

Lubricate crank parts every six months. Replace pedals when the surface is worn or if axle becomes “tight”or frozen.

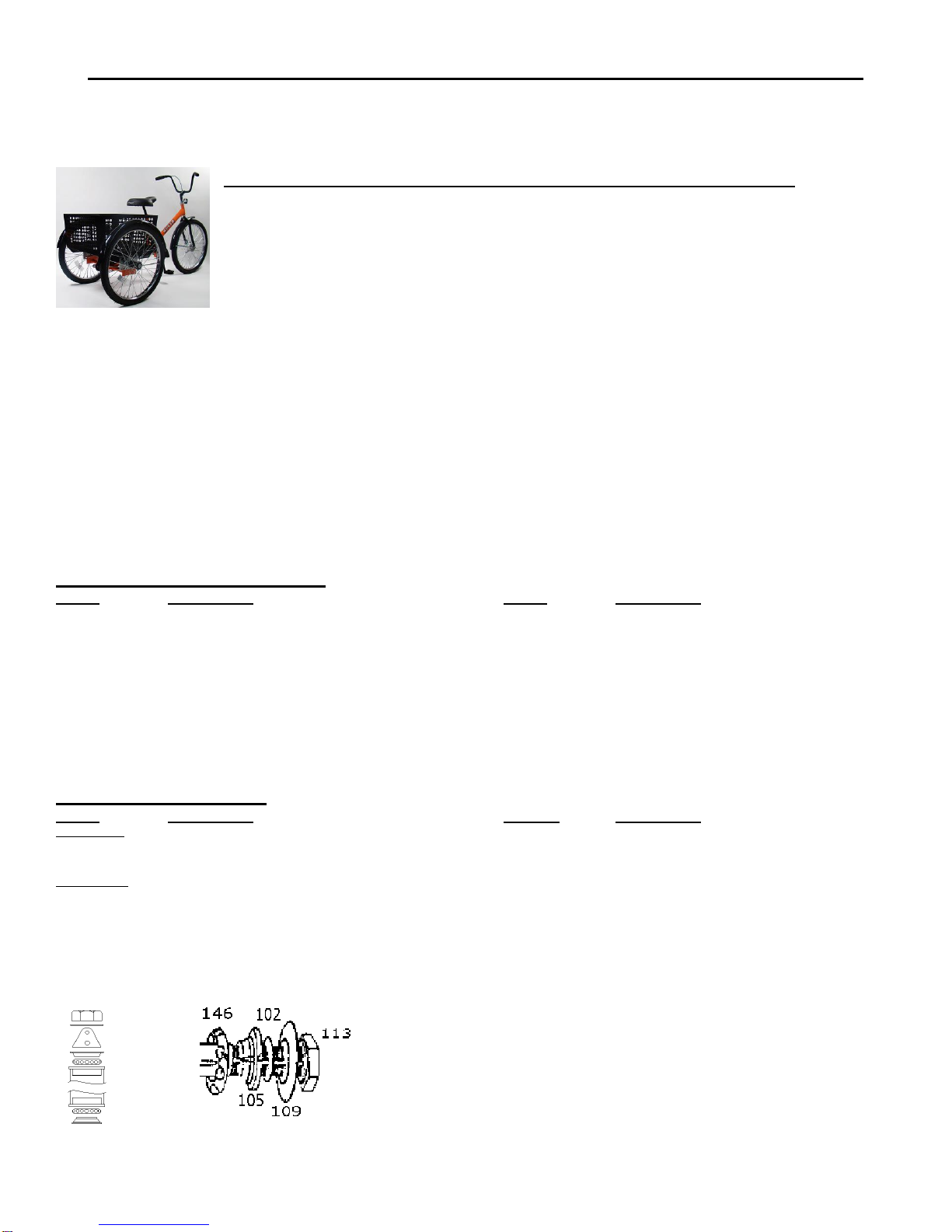

Drum Brake:

Your Worksman Mover Tricycle may be equipped with an automotive type front drum brake.

This brake is ideal for slowing your vehicle smoothly and reliably. It is engaged by squeezing

the hand lever on the handlebar. To use “Park”feature, when cycle is completely stopped,

squeeze hand lever and push in parking plunger button on lever. To disengage, simply

squeeze lever until parking plunger button releases.

Drum brakes are pre-adjusted at the factory. Readjust the cable tension as necessary using the

adjusting barrel so that wheel spins freely and stops when brake is applied. Always replace

worn brake cables (F719) and damaged hand levers. Internal parts kits are available for your

drum brake. (See parts list for part #’s.)

Coaster Brake (if applicable):

Foot activated coaster brakes are easy to use and reliable. To activate this internal brake, reverse the pedaling motion

until the brake engages. To avoid skidding and maintain control, apply care when braking. This is especially true on wet

surfaces. Apply brakes gently, gradually increasing pressure. Replace coaster brakes when they become worn. Check

chain tension regularly. Coaster brake hubs may make a vibrating noise under braking until they are broken in. For three

speed units, pause pedaling to help mesh gears. (Let the cycle coast.) This will make shifts smoother and will reduce

wear and tear on the hub. Do not shift when pedals are not moving as damage could occur.

Tires:

Always check for worn or damaged tires. We recommend 40PSI as proper level of inflation. Replace tires that are worn

or cut immediately. Replace or repair tubes that show leaks.

LIMITED WARRANTY:

This cycle is warranteed against faulty parts under the following conditions: this warranty does not cover any failure due to accident,

abuse, misuse, neglect or as the result of normal wear and tear, or improper assembly. The entire frame, including all welded joints, is

warranted to be free from defects and material for one year while in possession of the original purchaser. All other parts on this cycle,

except tires and tubes, are warranteed for Ninety days from the date of purchase. Repair and replacement of these parts is to be

according the Worksman cycles parts and service procedures and must be handled directly through the source where the cycle was

purchased. If upon examination of the parts in question, the Worksman Cycle dealer determines that it is defective, either repair or

replacement will be made at no cost except the cost of transportation and labor charges (if any). Unauthorized repairs or replacement

automatically voids warranty. Proper maintenance is required for warranty to be valid. In the event that it was determined that the

warranty claim is the result of misuse, abuse, improper maintenance or simply not defective or beyond the warranty period, Worksman

Cycles or the dealer will advise you as to the cost of repair, replacement or labor prior to performing any work or replacing any parts. If

you choose not to have the dealer or Worksman Cycles perform the work, the parts will be returned to you at your expense or

discarded if no reply is received within 2 weeks of notification. The sole responsibility of the manufacturer to the terms of this warranty,

if any, shall be the repair and/or replacement of the parts as indicated above. The liability of the manufacturer shall in no event exceed

the original purchase price of the product, and the manufacturer shall not be responsible for any consequential damages of any nature,

including, but not by way of limitation, damages for personal injury or property. This statement constitutes the exclusive expression of

warranties by the manufacturer and is in lieu of any or all other warranties such as expressed warranties, implied warranties, including

but not limited to warranties of merchantability, and fitness or purpose, are limited in duration for one year from the date of purchase of

the frame only and 90 days for all other parts, except tires and tubes which are not warranted. Worksman Trading Corporation is the

manufacturer. Misuse of the cycles including off road riding, installation of motors or power assists, alterations, repairs using parts

other than genuine Worksman Cycle parts voids warranty. Worksman Trading Corporation is not responsible for maintaining records of

serial numbers. Void where prohibited by state law.

Worksman Trading Corporation –94-15 100th Street –Ozone Park, NY 11416 –(718) 322-2000

www.worksman.com