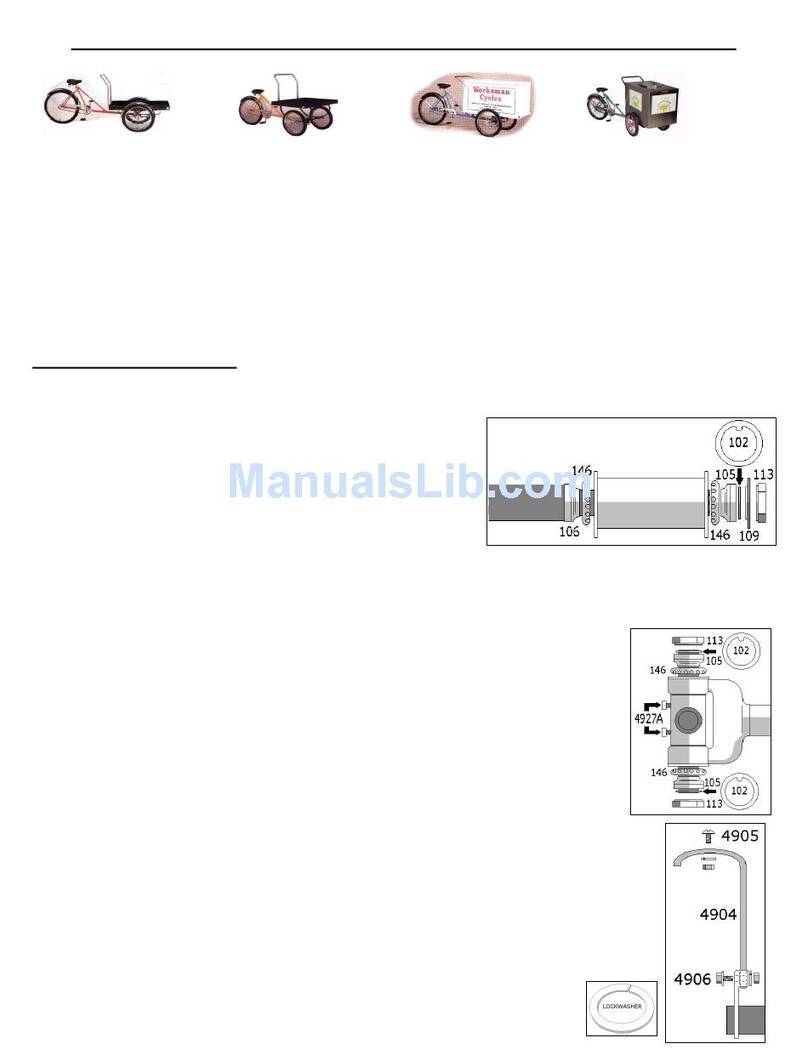

Rear Axle and Related Parts

Part # Description Part # Description

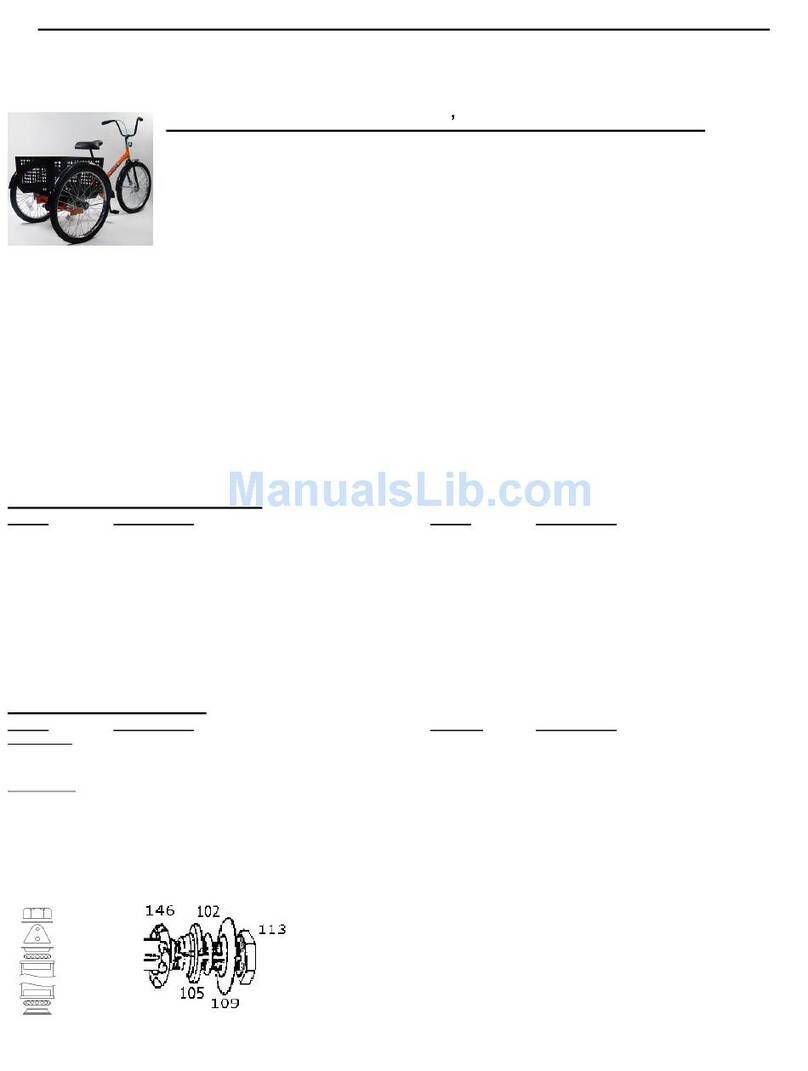

102 Key Washer 105 Adjusting Cone (threaded)

106 Stationary Cone (presses onto axle) 109 Dust Washer

113 Locknut - Left Hand Thread- Free Wheel Side) 146 Bearings (pair)

59A Locknut-Drive Side

130 Axle Parts Set(102,105,109,113,146,59A) 58 Rear Axle 34.5”

69 Fixed Drive Sprocket- 63B Key

(fits in axle slot to attach rear sprocket)

63C Set screw for 69 M13975 Side Bearing with Plate (each)

M13974 Center Axle Support Bearing 301M Coaster Brake w/Dual Sprockets

404NM 3 Speed Coaster Brake w/dual Sprockets SS721 Coaster Brake Internal Kit (for 301M)

SS13N-3 3 Speed Cable and Trigger for 404NM 4921 Springs and parts U-BOLTS

4926 U-Bolts for Leaf Springs

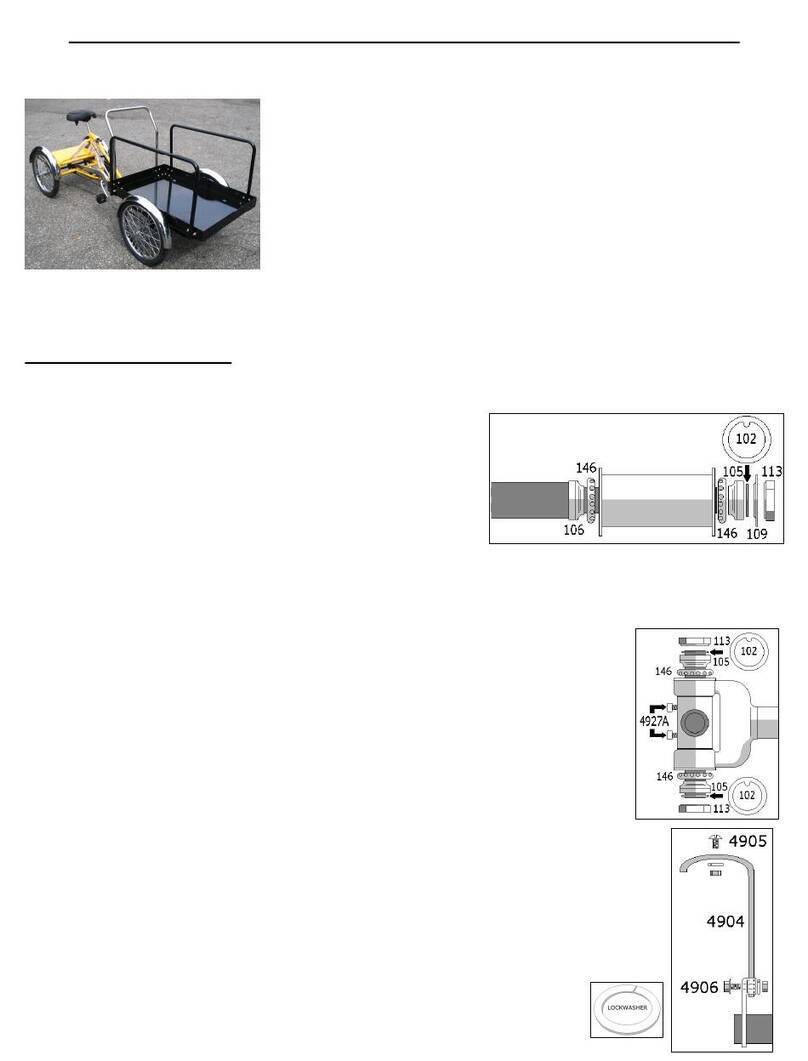

Crank and Crank Parts (Pedal Section) and Chains

Part # Description Part # Description

1265 Crank Parts (1266,1268,1269,1271,1272,1273,1274) 1265BMXS Deluxe Sealed Crank Set (Upgrade)

1266 Crank Bearings (pair) 1267 Complete Crank Set 36T(1265,1275,1380D)

1267F Complete Crank Set with 32 T Sprocket 1267H Complete Crank Set w/ 28T Sprocket

Note- The Mover Comes standard with a 32T front Sprocket and 1265 Crank part set. Smaller

Sprockets in the front will reduce gear ratio (easier to start pedaling) . The 1265BMXS is a heavier duty

upgrade for crank parts. Shown at right….1275 crank with 1265 hanger parts et.

1268 Cups for crank housing (pair) 1269 Stationary washer(inside)

1271 Key Washer- Outside 1271 Key Washer- Outside

1272 Adjusting Cone (threaded)-Outside 1273 Stationary Cone- Inside

1274 Crank Locknut 1275 Crank-forged- 6.5”

1380F Sprocket 32Tooth

1380H Sprocket 28 Tooth 7217 Pedal Set (Pair)

4910A Chainguard 4914A Chain Connecting Link(1/2x3/16”)

4914STR32 Chain 1/2x3/16”x187 (for 32T Sprocket 4914XX Chain- Short 3 1/2x3/16”x37

4914STR28 Chain 1/2x3/16”x185(for 28T Sprocket 4915 Chain Adjusters (for Coaster Brake)

Seats and Seatpost and Fenders, Baskets and Cabinets

Part # Description Part# Description

6910V-5 Saddle-padded w/5/8” clamp (standard) 6911V-5 Saddle-padded w/springs & 5/8” Clamp

4908M Seatpost- Solid Steel 4909M Square Head Bolt- (Secures Seatpost)

M13970 Basket fits Rear Platform- 23x22x15” Heavy Duty 3927STPT Rear Platform 38x26” w 3” Lip-Standard

M17350 Cabinet-23x22x11.5” fits on Rear Platform M17350J Jumbo Cabinet 23x22x20”

3927SUD Super Size Cabinet-in lieu of Platform(42x23x26”) 7228 Front Basket 21x15x9” w/bracket

139 Front Basket 18x13x6” w/bracket 82 Front Fender-26”

83A Brace- Front Fender

95 “L” Bracket to attach Front Fender to Fork 4907 Bolts, nut, washer (for 83A Brace)

4905 Bolt set for attaching 4902 to top of M13996 4907A Bolt Set to attach 82 to Fork

4906 Bolt Set for bottom of M13996 MSF2620-STR Side Fender Set (M2620-CB-STR)

.

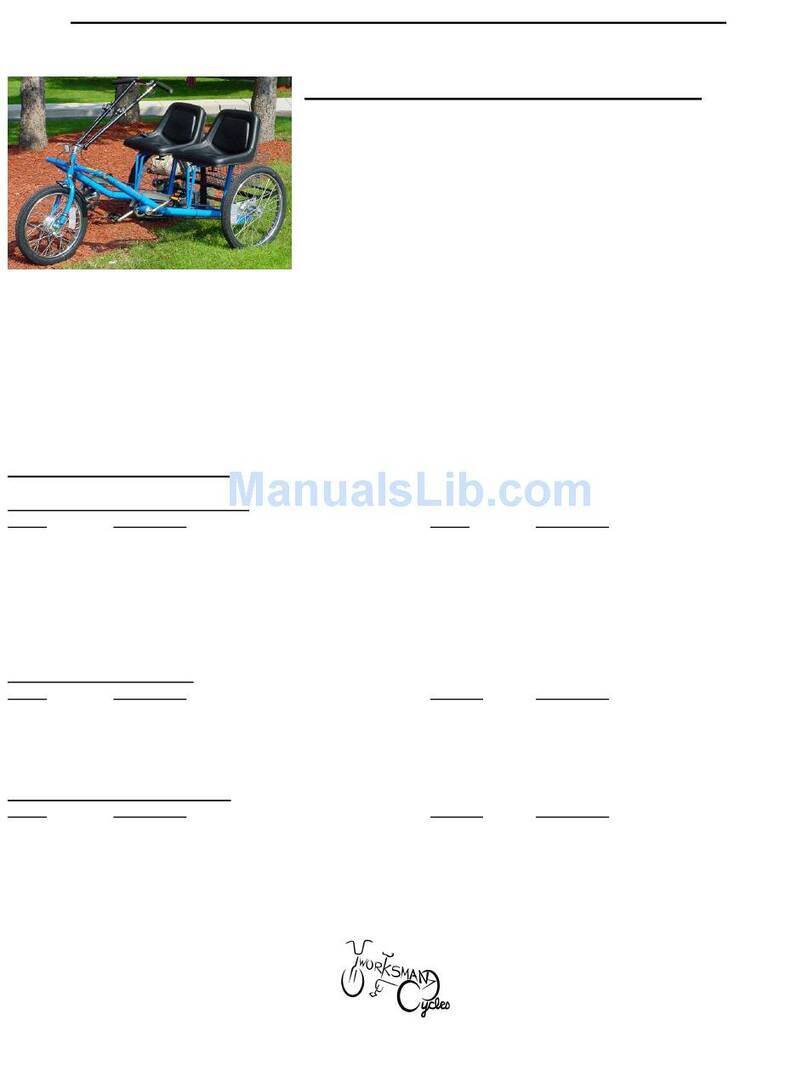

M13970 Rear Basket 6911V-5 Saddle 7228 Front Basket

23x23x16” Thickly Padded 21”x15”x9”

Part #’s and Specifications subject to change without notice as we are constantly seeking ways to improve our products. ---Worksman Cycles----

Parts List M2620-STR03