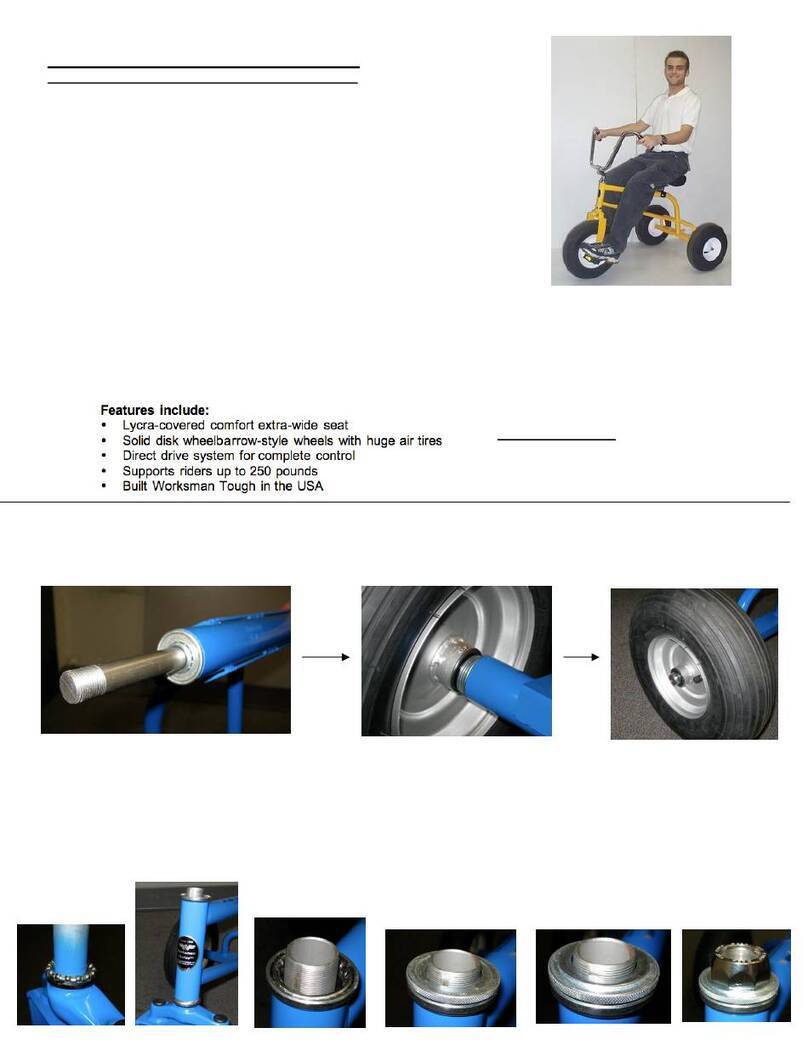

HERE ARE SOME OTHER EXCITING MODELS FROM WORKSMAN CYCLES!

Chariot Parent / Child Trike Folding Tandem Bike Mover M2626 w/ Jumbo Cabinet

Worksman Trading Corporation –94-15 100th Street –Ozone Park, NY 11416 –(718) 322-2000

www.worksmancycles.com Parts list EXEC07

LIMITED WARRANTY:

THIS CYCLE IS WARRANTIED AGAINST FAULTY PARTS UNDER THE FOLLOWING CONDITIONS: THIS WARRANTY DOES NOT COVER ANY

FAILURE DUE TO ACCIDENT, ABUSE, MISUSE, NEGLECT OR AS THE RESULT OF NORMAL WEAR AND TEAR, OR IMPROPER ASSEMBLY.

THE ENTIRE FRAME, INCLUDING ALL WELDED JOINTS, IS WARRANTED TO BE FREE FROM DEFECTS AND MATERIAL FOR ONE YEAR

WHILE IN POSSESSION OF THE ORIGINAL PURCHASER. ALL OTHER PARTS ON THIS CYCLE, EXCEPT TIRES AND TUBES, ARE

WARRANTIED FOR NINETY DAYS FROM THE DATE OF PURCHASE. REPAIR AND REPLACEMENT OF THESE PARTS IS TO BE ACCORDING

THE WORKSMAN CYCLES PARTS AND SERVICE PROCEDURES AND MUST BE HANDLED DIRECTLY THROUGH THE SOURCE WHERE THE

CYCLE WAS PURCHASED. IF UPON EXAMINATION OF THE PARTS IN QUESTION, THE WORKSMAN CYCLE DEALER DETERMINES THAT IT

IS DEFECTIVE, EITHER REPAIR OR REPLACEMENT WILL BE MADE AT NO COST EXCEPT THE COST OF TRANSPORTATION AND LABOR

CHARGES (IF ANY). UNAUTHORIZED REPAIRS OR REPLACEMENT AUTOMATICALLY VOIDS WARRANTY. PROPER MAINTENANCE IS

REQUIRED FOR WARRANTY TO BE VALID. IN THE EVENT THAT IT WAS DETERMINED THAT THE WARRANTY CLAIM IS THE RESULT OF

MISUSE, ABUSE, IMPROPER MAINTENANCE OR SIMPLY NOT DEFECTIVE OR BEYOND THE WARRANTY PERIOD, WORKSMAN CYCLES OR

THE DEALER WILL ADVISE YOU AS TO THE COST OF REPAIR, REPLACEMENT OR LABOR PRIOR TO PERFORMING ANY WORK OR

REPLACING ANY PARTS. IF YOU CHOOSE NOT TO HAVE THE DEALER OR WORKSMAN CYCLES PERFORM THE WORK, THE PARTS WILL

BE RETURNED TO YOU AT YOUR EXPENSE OR DISCARDED IF NO REPLY IS RECEIVED WITHIN 2 WEEKS OF NOTIFICATION. THE SOLE

RESPONSIBILITY OF THE MANUFACTURER TO THE TERMS OF THIS WARRANTY, IF ANY, SHALL BE THE REPAIR AND/OR REPLACEMENT

OF THE PARTS AS INDICATED ABOVE. THE LIABILITY OF THE MANUFACTURER SHALL IN NO EVENT EXCEED THE ORIGINAL PURCHASE

PRICE OF THE PRODUCT, AND THE MANUFACTURER SHALL NOT BE RESPONSIBLE FOR ANY CONSEQUENTIAL DAMAGES OF ANY

NATURE, INCLUDING, BUT NOT BY WAY OF LIMITATION, DAMAGES FOR PERSONAL INJURY OR PROPERTY. THIS STATEMENT

CONSTITUTES THE EXCLUSIVE EXPRESSION OF WARRANTIES BY THE MANUFACTURER AND IS IN LIEU OF ANY OR ALL OTHER

WARRANTIES SUCH AS EXPRESSED WARRANTIES, IMPLIED WARRANTIES, INCLUDING BUT NOT LIMITED TO WARRANTIES OF

MERCHANTABILITY, AND FITNESS OR PURPOSE, ARE LIMITED IN DURATION FOR ONE YEAR FROM THE DATE OF PURCHASE OF THE

FRAME ONLY AND 90 DAYS FOR ALL OTHER PARTS, EXCEPT TIRES AND TUBES WHICH ARE NOT WARRANTED. WORKSMAN TRADING

CORPORATION IS THE MANUFACTURER. MISUSE OF THE CYCLES INCLUDING OFF ROAD RIDING, INSTALLATION OF MOTORS OR POWER

ASSISTS, ALTERATIONS, REPAIRS USING PARTS OTHER THAN GENUINE WORKSMAN CYCLE PARTS VOIDS WARRANTY. WORKSMAN

TRADING CORPORATION IS NOT RESPONSIBLE FOR MAINTAINING RECORDS OF SERIAL NUMBERS. VOID WHERE PROHIBITED BY STATE

LAW.

RULES FOR SAFE RIDING AND RESPONSIBLE OPERATION: Carefully read this manual before operating the cycle.

·It is the responsibility of the person who completes the assembly to properly install all parts included and to inspect the cycle prior to riding to

insure proper operation.

·Operator is responsible for required maintenance to keep the cycle in good operation condition.

·Observe all traffic regulations in the operating environment. (Stop signs, etc.)

·Keep to the right and in a straight line. Tricycles tend to pull toward the non-driven wheel side. This is normal. Ride in single file.

·Do not ride outdoors at night, and have appropriate signaling device as needed. (We recommend the 3973 Mega Horn.)

·Give pedestrians the Right of Way.

·Always look around you to understand the riding environment and hazards.

·Do not carry passengers, and check brakes prior to riding.

·Slow down when approaching turns or intersections. Tricycles are meant for slow pace rides, not for racing.

·Use proper hand signals when turning or stopping.

·Recommended safety options include, but are not limited to, an approved helmet, audible warning device, front/rear lights and/or reflectors.

·Never ride the cycle if there are known repairs required.

·Do not exceed the recommended weight capacity of the cycle. (250 lbs., including the rider.)

·Always secure cargo with appropriate tie down straps. StarLite Tricycles are not intended or warranteed for commercial use.

·Wipe surface of cycle clean and dry when exposed to corrosive substances or environment.

·Operate cycle at slow speeds, particularly in high traffic areas.

·Operators of cycles should be in good physical condition. Ride at your own risk.

·Wear proper riding attire. Check shoelaces and pant legs prior to riding so they do not become engaged in the chain and sprocket.

·Ride only on smooth, paved surfaces. Do not use off road.

·Do not operate a tricycle on steep grades. They are designed for relatively level, paved surfaces only.

·Always replace worn parts with genuine Worksman Cycle Repair Parts.

·Always keep both hands on the handlebars. Tricycles have a tendency to pull slightly to one side.

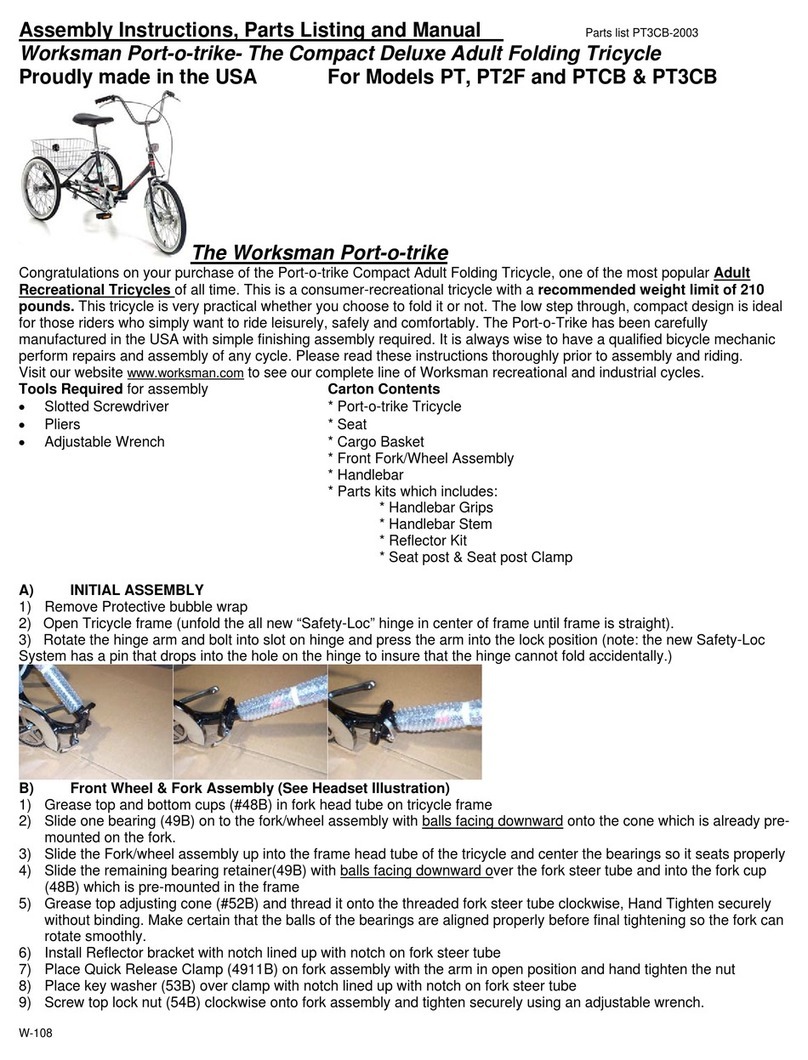

Worksman highly recommends having the Executive tricycle built by a professional and experienced bicycle

mechanic to avoid errors in assembly. Failure to have this tricycle professionally assembled by a qualified

bicycle mechanic puts the rider at risk of injury or death.

Visit us online at www.worksmancycles.com or call us at (888) 3-WHEELER!